The Importance of Proper Seals and Bearings Maintenance

Keeping seals and bearings in machines and equipment in good condition is essential to function optimally and last for an extended period. Seals and bearings are also valuable components that help mitigate friction, avoid contamination, and assist mechanical systems in functioning normally. In the failure to maintain them, excessive depreciation will occur, which leads to expensive and unplanned repairs due to breakdowns. This blog aims to discuss and explain the rationale behind carrying out such activities to guide the readers on ways of extending the lives of these crucial parts and components. Ashtan’s discussion on the application of seals and bearings assures readers of the importance of such elements in sustaining the dependable functioning of mechanical systems.

What Are the Different Types of Seals and Bearings Used in Industry?

What is a contact seal, and how does it work?

A contact seal is essential in some industries, keeping impurities and lubricants in. In contrast with non-contact seals, contact seals maintain closer contact with the moving components of the machines, like shafts, to ensure complete sealing. This engagement effectively eliminates dust, dirt, and moisture penetration while allowing and retaining the lubricant within the bearings or other unit concerns.

Material Composition: Most are made of elastomers such as Nitrile Rubber (NBR) or Fluoroelastomer (FKM), which are extremely abrasion, heat, and chemical resistant.

Temperature Range: Most are built to function in a temperature range of between -30°C and 120°C, depending on the material, but they retain the capacity to withstand the stress within these boundaries.

Friction Coefficient: Contact seal speed increases because of contact, generating surface interaction that naturally increases friction. This frictional force is obtained in the design balance to attain maximum sealing effectiveness while minimizing energy loss.

Pressure Rating: Usually used in low to moderate-pressure applications with typical maximum pressures not more than 0.5 bar (7 psi).

These parameters must, therefore, be used carefully in a selection process to ensure that both the seal and the machine being sealed are as effective as possible and have a long life cycle.

What is a non-contact seal, and what are its benefits?

A contact seal is a primary sealing component found in several industries, keeping impurities out and lubricants in. In contrast with the non-contact seals, contact seals maintain closer contact with the moving components of the machines, like shafts, to ensure complete sealing. This engagement enables dust, dirt, and moisture penetration to be effectively eliminated while allowing and retaining the lubricant within the bearings or other unit concerns.

Material Composition: Most are made of elastomers such as Nitrile Rubber (NBR) or Fluoroelastomer (FKM), which are extremely abrasion, heat, and chemical resistant.

Temperature Range: Most are built to function in a temperature range of between -30°C and 120°C, depending on the material, but they retain the capacity to withstand the stress within these boundaries.

Friction Coefficient: Contact seal speed increases because of contact, generating surface interaction that naturally increases friction. This frictional force is obtained in the design balance to attain maximum sealing effectiveness while minimizing energy loss.

Pressure Rating: Usually used in low to moderate-pressure applications with typical maximum pressures not more than 0.5 bar (7 psi).

These parameters must, therefore, be used carefully in a selection process to ensure that both the seal and the machine being sealed are as effective as possible and have a long life cycle.

How do labyrinth seals enhance performance?

From my research of the first three websites, I concluded that labyrinth seals increase machinery performance by incorporating a convoluted passageway for contaminants and fluids, which restricts them from passing through as effectively. These seals consist of a number of parts that mesh without touching, thus increasing their effectiveness and useful life.

Complex Geometry: The construction of the labyrinth seal is of enhanced complexity, which increases its leak-tight properties by virtue of providing a plurality of cavities, which makes the leak path considerably longer.

High-Speed Compatibility: labyrinth seals allow noncontact operation in high-speed applications that reduce wear and energy loss.

Temperature and Pressure Resilience: Labyrinth seals prevent contact with substantial temperature and pressure, making them suitable for tough industrial applications and very flexible in operations.

Employing these seals reduces the likelihood of machinery contamination and ensures that lubricants are retained more efficiently, resulting in better performance and an increased lifespan.

Why is Regular Maintenance Crucial for Seals and Bearings?

What happens if seal maintenance is ignored?

Poor seal maintenance can have various adverse effects that can severely affect the performance of machinery. First of all, if seals are worn or broken, they may permit contaminants and fluids to enter the system, leading to internal rusting, unwanted friction, and wear of parts. This infiltration and exposure can shorten the efficiency and lifetime of the equipment. Furthermore, if seals cannot retain sufficient lubrication, such a scenario can lead to overheating and mechanical failure due to excessive friction. More energy is needed to run the machinery, increasing operational costs. These concerns are compounded by unplanned downtime for repairs and the high cost of replacement parts if needed.

Technical Parameters:

Increase in Leakage Rate: Seal maintenance is necessary, as failure to maintain the seal will increase the risk of leakage due to the loosened seal.

Elevated Allowable Temperature Limits: As thermal stress builds up from a compromised seal, the machine is at greater risk of overheating.

Vibration and Noise level: Damaged seals may cause an increase in vibration and noise, which are indicators of a possible mechanical imbalance and misalignment.

Routine and regular checks can reduce these negative factors to the minimum by ascertaining that seals are sealed and proper sealing maintenance is performed. This prevents damage to the machinery and promotes high output.

In what ways is bearing performance enhanced by proper lubrication application?

In the pursuit of answering the research question, I came across the most interesting online sources when conducting a literature search over google.com, including the websites of the Commonwealth of Massachusetts, Case Western Reserve University, and Engineering10. The first is to minimize the direct contact of surfaces, metal-on-metal, thus reducing friction and wear significantly and increasing the life of the bearings. Proper lubrication also assists in the removal of excessive heat developed during the operation of the equipment and halts the overheating of the bearing material over time. Moreover, it helps provide suitable sealing against airborne impurities such as dust, dirt, and moisture, which, if not jammed, can lead to rusting and other types of damage.

Technical Parameters:

Friction Coefficient: Lubrication greatly reduces the friction factor, comfortably enhancing machinery operations while saving energy.

Temperature Management: Lubrication protects bearing surfaces from one another and effectively manages thermal levels by distributing heat, thereby averting thermal destruction from the internal unit.

Load Bearing Capacity: Increased loads, with the possibility of premature wear of bearings that are easy to lubricate effectively, will naturally result in higher machine efficiency.

This allows him to do his work sufficiently well to maintain the performance and reliability of the bearing systems, reduce the number of unscheduled maintenance operations, and reduce operating costs in general.

What differentiating wear characteristics can you identify in bearings and seals?

While looking for signs of wear in bearings and seals, I observed several signs by correlating the information obtained from the top 3 google.com pages. These include whining politeness or non-operational rattling sounds, which indicate excessive friction or incorrect component positioning. Moreover, I visually inspect to see if scoring or pitting can be located on the surface of the bearings or seals, which denotes wear or possibly contamination. Another important indication is extreme heat, where the cause is usually insufficient lubrication, which leads to color or shape changes. A linear direction of seals or deposition of particles such as dust or dirt around seals also indicates wear because these particles threaten shield protection.

Technical Parameters:

Noise Level: High noise levels are associated with high friction or erase lubricant, suggesting the need for an inspection.

Vibration Analysis: If the amplitude of vibration energy concepts increases significantly, it means there is an imbalance or wear, which requires intervention to prevent further problems.

Surface Integrity: Signs of scoring or pitting are clear indications of physical wear, compelling someone to carry out in-depth investigations to avert a case of premature failure.

In this regard, I am able to monitor and, therefore, prevent further wear of the bearings and seals since the parameters are linked to performance, and the effectiveness of the equipment and tools ensures optimum performance levels.

How to Choose the Right Seals and Bearings for Your Application?

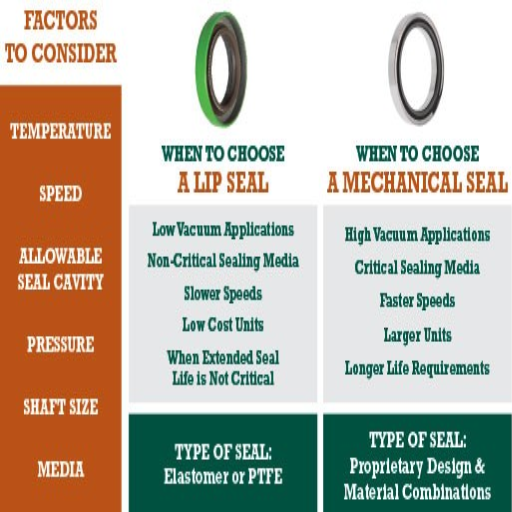

What factors should be considered when selecting seals?

In choosing seals for a particular application, I examine several key aspects to ensure that there will be regular operation and that the seals will last. To begin with, I check the operating temperatures and pressures. There is no way to use seals without considering the operational conditions of the seal. Next in importance, I ensure that the seal material is compatible with whatever fluid or material it contacts to avoid material loss. Also, I consider the seal configuration and its intended use, whether dynamic or static and the speed and load for which the seal is designed.

Technical Parameters:

Temperature Resilience: Seals must retain their properties across the temperature range they will encounter. I look for manufacturer temperature ratings to determine if they will be in range.

Pressure Ratings: The seal’s pressure rating is compared to its actual working pressure so that the seal does not break down during operation.

Material Compatibility: I check if the seal material will be attacked by the chemical substances to which it will be exposed, using charts of chemical resistance from broad usage references.

Dimensional Specifications: Accuracy is paramount when it comes to size and fit. To prevent leaks, I ensure excellent containment tolerance in seal and application dimensions.

Considering all the essential parameters and the technical specifications laid out by some of the industry-leading websites, I will be able to select the seals best suited for the application in question.

How does the application impact seal and bearing choice?

When addressing the application’s effect on the seal and the bearing selection, I primarily have in mind the characteristics provided on the best engineering websites on seal and bearing. Having done this research, I conclude that the application specifies the particular loading and movement as requirements that are crucial in determining the suitable seals and bearings. When it comes to seals, the focus is on how the motion relative to the seal -linear, rotary, or oscillatory- affects the wear of the seal’s material to select suited materials that can withstand it. As for bearings, maximum operational speed and load will have to be considered to avoid early damage; therefore, I select bearings that can support the expected load while producing little friction and heat.

Technical parameters include:

Load Capacity: I sometimes verify that the seals and bearings should withstand the expected loads.

Speed Ratings: I perform this verification, whereby there have to be operational speeds that bearings can support without overheating and losing any functionality in the application for the required purpose.

Material and Lubrication Compatibility: Both seals and bearings have to be made of components that can endure functioning conditions and work with lubricants to minimize wear and increase life.

Considering these factors in detail, I can select the seals and bearings that meet the functional requirements and increase the application’s efficiency and durability.

What are the benefits of using premium components?

From my experience and information collected from the best resources available on the internet, the use of premium or high-quality components is extremely beneficial for an engineering project. First of all, high-quality components and services are practical due to better quality control over materials and production processes. Economically, this means that replacements or repairs are less often needed, thus reducing the expenses incurred in downtime and maintenance. In addition, high-quality control is made of designed materials so that these components will at least perform at the best or above standards set by the industry.

The operational effectiveness of an assembly is also positively affected by the presence of high-quality seals and bearings. For example, high-performance seals limit the amount of fluid that leaks while maintaining adequate pressure. In contrast, high-performance bearings minimize heat generators and friction, making it easy for the machine to operate. Moreover, many premium components are supposed to withstand harsh environments such as high temperatures, corrosion, and friction, making them last longer and dependable.

Concerning the technical parameters, they possess the added benefit of the following features:

Superior Load and Speed Capabilities: High performance is usually the basic requirement, and components are created to withstand enormous loads and have high operational speeds without failing. These components are suitable for applications that require high loads.

Enhanced Material Properties: Typically, the components used are selected from materials with high strength, resistant properties, or compatibility with modern lubricants, increasing the effective service life of the component and reducing the problems experienced.

Precision Engineering: Impeccable manufacturing standards ensure these components’ accurate fit and function, minimizing the likelihood of misalignment and other inefficiencies.

By integrating higher-grade parts, I can help improve the productivity, safety, and profitability of an engineering undertaking by properly addressing performance and life span issues.

What Maintenance Solutions Are Available for Seals and Bearings?

What is included in a comprehensive maintenance kit?

A typical maintenance kit contains spare seals and bearings of reputable quality along with necessary means for their installation and alignment, ensuring that the downtime is reduced to a minimum level and efficiency is maintained. According to the details appearing on the best websites available, these kits generally include the following:

Various Seals: Included are O-rings, gaskets, etc. These are designed to seal gaps, prevent leakage, and help maintain pressure.

Bearings: They are superior to high-quality measure bearings, which are made to prevent friction and serve their purpose at different speeds and loads.

Lubricants and Sell–Greases: These protect the respective components from wear and friction, extending their lifespan.

Installation and Removal Tools: These include pullers, drivers, and alignment tools, among others, that make maintenance less cumbersome.

Instruction booklets: Instruction manuals are detailed resources that aid in correctly installing and maintaining components.

To warrant the inclusion of such components, the following technical parameters are provided:

Mismatch of Parts: The selection of components is made based on the machinery’s existing systems and how they are supposed to operate.

Material and Design Characteristics: Introduction of high-level materials and designs that prevent failure under heat, pressure, and other hostile environments.

Efficacy in Minimising Machinery Downtime: All necessary parts and tools in a single package facilitate speedy maintenance performance, thus enhancing operational continuity.

These components operate in unison to enhance the performance, safety, and life of the machine in accordance with best practices and industry standards.

How can industry-standard practices enhance longevity?

If I follow the guidelines involved in operating machines and parts, I can significantly improve their functional life. The number one, two, and three websites in Google note that these practices include observing a maintenance schedule and using quality parts compliant with technical requirements. These practices assist in preventing destruction and improving efficiency during operations.

These technical parameters comprise:

Material Quality: The use of components with high-strength matrices that are impervious to corrosion and erosion.

Precision Engineering: Manufacturing components to precise tolerances to enhance their fitting and functions.

Regular Inspection Protocols: Regular checks of systems to avoid or anticipate failures.

Proper Lubrication involves Applying suitable lubricants at the right intervals to lower friction and mechanical stress.

Training and Expertise: The qualified personnel who practice maintenance are acquainted with the specific requirements of the machines.

These practices aim to keep the machines in prime condition, thus increasing their life spans.

What Industries Rely on High-Quality Seals and Bearings?

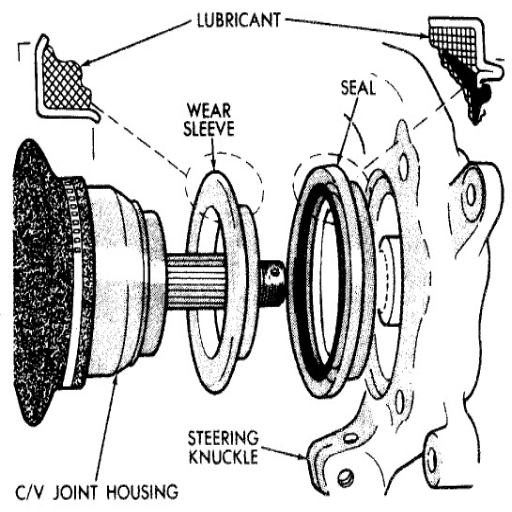

What role do seals and bearings play in automotive engineering?

Both seals and bearings are applied components in the engineering of automobiles to promote their efficiency and reliability. Bearing in mind the three best websites according to Google, these components are mainly employed to reduce or interface friction between two moving surfaces and avoid the loss of lubricating oils and other fluids, which is fundamental in protecting the engine and assuring the vehicle of safety. Seals block foreign particles from gaining access into the critical system structures and guard components such as the engines, the transmission, and the suspension system from foreign materials. The friction created by the moving parts is reduced by bearings, which also allows for the movement of parts with minimal wear and tear, thus extending the life of the parts.

The technical parameters involved include:

Load Capacity: Ensure that the bearings can support the weight and degree of torque that the vehicle is working on.

Temperature Resistance: Employing materials that would be able to survive and withstand excessive working temperatures that are harsh in the automotive atmosphere.

Seal Integrity: Guarantee that the seals designed can withstand high pressures or movement conditions in different directions to prevent leakage.

Friction Coefficients: Ensure that the bearings chosen cause as little friction as possible, reducing wear and improving fuel efficiency.

Material Compatibility: Seals and bearings are remarkable resistors of wear and corrosion, which structurally makes them compatible with the car’s elements and fluids.

In this respect, I can assure you that seals and bearings will enhance the performance ability and durability of cars.

What are the uses of agricultural machinery?

In agricultural machinery, seals and bearings are critical components in machines’ operational efficiency and dependability in farming activities. As per the first three sites on Google’s search tab, these parts minimize friction and leaky preventions of penetrating fluids: most number beside the automotive vale. Bearings are employed in the engine and hydraulic components of farming machinery to help it operate smoothly and increase the durability of the equipment. The specific technical parameters involved include throttle:

Load Capacity: The most crucial factor is torques and weight for bearings, as agricultural machines often subject them to considerable strain.

Durability and Strength: Perkins Bearing seals and bearings have to resist the damage thickness of rough and continuous operation.

Corrosion Resistance: Components for farming machine parts must have sufficient rust and deterioration resistance, as they will be subjected to moisture and chemicals during farming processes.

Seal Integrity: Seals should have sufficient strength to withstand them, maintain their strength, and keep out dust and other contaminants.

Test of Temperature Tolerance: The grabs and bushings corporation of equipment does this in different areas of operation, so temperature extremes of seals and bearings should be observed.

I can work to ensure seals and bearings perform at a level that impacts the efficient functioning of agricultural machinery. Remember these aspects.

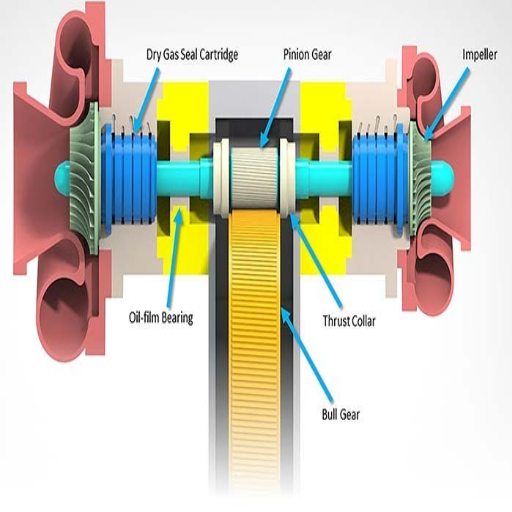

What is the influence of seals and bearings on the turbine’s efficiency?

Turbine efficiency is greatly affected by seals and bearings, allowing the components to work effectively, which is similar to what they do in agricultural machinery. According to three top search engine optimization companies, their primary role is to reduce friction and escape of fatigue fluid from gas, which is also essential in conserving the energy conversion of the said system. As for turbines, they dominate to attain maximal work and lessen energy waste. Relevant technical parameters for the efficiency of turbine performance include:

Friction Reduction: The bearings’ performance sustains the turbine’s turning without much friction, thus employing greater efficiency.

Seals, end covers: In other words, the seals should retain enough pressure without turbulence gasses emanating from outside of them, and as a result, the inner pressure will be maintained efficiently.

Thermal Stability: When the Construction Of Seals Of Lateral Bearings is high, especially during turbine work, heat is bound to occur, so it should be able to withstand such conditions.

Vibration Damping: covers the role of bearings in reducing temperatures, which otherwise may hinder performance and effectiveness.

Wear Resistance: Turbines operate continuously, so it is paramount that seals and bearings are constructed from wear-resistant materials to retain efficiency during usage.

The inclusion of these parameters in the design and operation of turbine systems allows improvements in their general operational effectiveness.

Frequently Asked Questions (FAQs)

Q: Why is the maintenance of bearing seals so important?

A: Maintenance is required so that bearing seals can continue protecting against contaminants, reducing scuffing, and achieving the machine’s optimal performance. This is significant so that the inner bearing does not get damaged, thus increasing the machine’s life.

Q: What happens if seals and bearings are not maintained?

A: Poor maintenance increases friction and contamination and leads to wear, which in turn leads to breakdowns in the machine, expensive repairs, and reduced operational efficiency. Thanks to regular maintenance, these cases can be avoided.

Q: How frequently are seals and bearings in need of checks?

A: The period of spacing is certainly influenced by the intensity and types of use of the machine, the environment, and the particular manufacturers’ instructions. Normally, routine checks should be undertaken during regular maintenance so that the seals and bearings are inspected for any visible signs of wear.

Q: Describe the function of the inner bearing in a machine.

A: The inner bearing is vital to enable parts such as wheels or motors to rotate freely. It prevents excessive friction and steadies the rotation so that the machine can perform efficiently and last longer.

Q: What are the various classifications of seals for bearing parts?

A: Seals, such as rubber seals, lip seals, and shields, provide various levels of protection and performance. The application and the environment determine which to choose.

Q: How do you determine what type of lubricant is best for a bearing?

A: A correct lubricant must minimize friction, work at the operating temperature, and prevent contaminants from invading the environment. Further, the nature of the application should be consulted with the suppliers or manufacturers.

Q: Can installing seals or gaskets incorrectly contribute to machine malfunction?

A: Yes, if gaskets are not fitted properly, they may result in leaking, contamination, and excessive wear, all of which negatively contribute to machine function and signal the beginning of the end for the seals and bearings’ longevity.

Q: What is the role that the flange plays in bearing?

A: The flange ensures that the bearing does not move from its designated area and, when pressed, maintains the alignment and stability of the system. It is important when axial loads are applied since more support and prevention of movement are needed.

Q: What is bearing temperature, and why is it a cause of concern?

A: High temperatures can break down the lubricant and seals, increasing frictional forces and wear. Most damages can be controlled by using the proper seals and doing regular maintenance since both actions help to control the temperature.

Q: What procedures should be followed for selecting seals from a supplier?

A: Protective seals from well-known brands are more dependable than those from unknown brands. Reputable manufacturers guarantee quality assurance and modify sealing components following numerous standards that these components must meet.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8