Tie Rods: The Unsung Heroes of Your Car’s Steering System

When it comes to automotive components that ensure a smooth and reliable driving experience, tie rods often go unnoticed. These essential parts play a critical role in the steering mechanism, linking the steering rack to the steering knuckles and directly influencing how accurately a car responds to the driver’s inputs. Despite their relatively small size, tie rods must withstand significant stress, maintain precise alignment, and ensure stability during operation. This article provides a detailed exploration of tie rod functionality, their importance, common issues to watch for, and maintenance tips to ensure optimal vehicle performance. Whether you’re an automotive enthusiast or simply curious about what keeps your car steering seamlessly, understanding tie rods will deepen your appreciation for the intricate mechanics under your car’s hood.

What are the signs of a bad tie rod?

How does a loose tie rod affect steering?

A loose tie rod can drastically damage how the driver controls the vehicle and how stable it is overall. If there is a loose tie rod, it results in too much movement of the steering wheel without proper movement of the car, which leads to a driver not being able to steer the vehicle in the desired direction.

- Steering Wheel Play: When drivers face loose or slack tie rod ends, any movement exceeding a couple of inches would be classified as loose.

- Alignment Angles (Toe settings): A loose tie rod may stem from irregular toe angle in the normal toe alignment which would be expressed in degrees. Essential toe alignment changes from car to car, as expected, but it should usually be under the manufacturer requirements (for passenger cars, this is assumed to be -0.1 degrees).

- Vibration Frequency: Any abnormal shaking of the steering that seems to persist at a certain speed can be traced back to the tie rod which makes it tangible to identify together with bad wobbly worn out tires and bad suspension mounting points.

For effective steering safety and prolonging the life of related elements, early identification and rectification of a loose tie rod are essential.

What sounds indicate a failing tie rod?

Worn-out tie rods make a lot of noises that, at times, make diagnosing the problem all the more easier. Every common sound associated with it entails:

- Clunking or Knocking Sounds: Commonly heard when a person turns a steering wheel or when a vehicle is moving over rough surfaces, these sounds stem due to excessive motion within the tie rod joints due to either worn out ball sockets or a combination of both.

- Squeaking Noises: Steering movement at times can cause squeaking sounds which normally arise from insufficient lubrication in the tie rod ends.

- Grinding Sounds: An even advanced form of wear can make the tie rod rub against itself which results in a grinding noise.

Promptly addressing these symptoms is crucial to improving the effectiveness of steering or avoiding possible safety risks, which makes regular inspection of the area important.

How do damaged tie rods impact driving safety?

What happens if a tire rod fails while driving?

The failure of a tie rod while driving can enable the car to turn, but with a severe loss of accuracy. It leads to a loss of control over a vehicle’s directional axis as it breaks the linkage between the steering mechanism and the wheels. A complete loss of control will result in the most severe impact, while progressive damage will be less severe but will enable the user to steer the vehicle with erratic steering behavior.

- Steering Angle Deviation: In case of a failed tie rod, the wheels of the vehicle can pivot freely, causing a deviation from the angle at which the vehicle is intended to turn, which is usually at 1 degree to 2 degrees towards the alignment point.

- Toe Alignment: A failed or damaged tie rod impacts greatly the vehicle’s toe alignment which should remain within the specified tolerance (within -0.1 to -0.3 degrees.). Incorrect toe alignment can result to excess tire wear and poor vehicle response.

- Response Time: A working steering system is required for quick response since the delay in input response is measured in milliseconds. A damaged tie rod delays or eliminates this function, which can cause a threat, specially at higher speeds.

Vehicle safety and performance can easily be compromised if there is no immediate inspection and repair of a damaged tie rod. This performance will further degrade mechanically over time.

Can you drive with a bad tire rod?

Neglecting a worn tie rod poses great risk for safety, which is why driving around with one is discouraged. Personally speaking, my recommendation would be to strictly avoid this advice since the failure of a tie rod or steering system negatively impacts the overall functioning of a vehicle. A failing or damaged tie rod will greatly affect the level of control a driver has while steering an automobile, resulting in uneven wear on tires coupled with play. Complete failure of a tie rod can lead to loss of steering control altogether, which can be life threatening.

- Steering tolerances: within the desired alignment tolerances of ±0.05 degrees that a tie rod should maintain, it greatly helps in minimizing wearing of tires.

- Load bearing: under normal driving conditions, the average force that a tie rod can withstand is over 1000lbs. wear and tear on a tie rod will bring a loss in ability to support such loads which in return can greatly increase risk of failure.

- Vibration damping: left unattended, the burn out of a tie rod leads to lack of stabilization for wheel motion resulting in vibrations which become noticeable over 40mph.

Given these factors, the threats far overpass any need to keep driving. My strongest recommendation is to have the vehicle thoroughly examined and serviced without delay so that both you and everyone else on the road do not get put in harm’s way.

How do worn tie rods affect vehicle control?

Vehicle control is significantly compromised with worn tie rods because of lost steering accuracy and stability. When a tie rod is worn out, the connection from the steering rack to the wheel becomes loose, resulting in a lot of play in the steering mechanism. This phenomenon leads to inconsistent or delayed steering response which is easily observed during cornering or other sharp movements.

- Steering Angle Deviation: A simplified explanation for most drivers is that a damaged tie rod needs realignment, which changes the steering angle of the working wheel. It can lead beyond a defined limit, usually ±0.5 degrees, and cause uneven wear on the tire surface.

- Toe-in/Toe-out Alignment: Altered toe alignment caused by worn tie rods will change the geometry, which is vital in ensuring directional stability.

- Steering Force Transmission: With reduced tensile strength of the tie rod due to wear, the driver’s steering control becomes compromised because of the failure to transmit the required steering force appropriately.

- Vibration Frequency: For frequencies above 10 Hz, a faulty tie rod can worsen oscillation, which may make handling more difficult at higher speeds.

For optimal vehicle safety and performance in a variety of driving conditions, worn tire rods should be addressed right away.

When should tie rods be replaced?

What is the typical lifespan of tie rods?

Depending on usage and driving conditions, tie rods can last anywhere between 50,000 to 100,000 miles and can increase with proper vehicle maintenance. Several driving conditions can impact the life expectancy of a tie rod, including:

- Driving Environments: Rough roads with potholes or off-road driving places a greater mechanical strain on vehicles undergoing increased usage which leads to faster deterioration of the tie rods.

- Material Durability: Tie rods crafted from steel or alloy and treated with heat possess a greater resistance to both fatigue and the ultimate failure of tensile loading which makes them higher quality.

- Lubrication and Seals: Tie rods with grease seals intact protect the internal space from contaminants that corrode or wear out as a result of friction. Proper maintenance means less internal friction, so the seal can protect the tie rod longer.

The planned examinations while verifying alignment or while conducting suspension service are essential for detecting preliminary indicators of deterioration and confirming that the tire rods fulfill their designed functional requirements.

How often should tie rods be inspected?

For most vehicles, these components should be examined as part of seasonal maintenance for a tune-up and alignment that usually occurs every ten to fifteen thousand miles. In the case of vehicles with severe driving patterns, such as those operating with heavy loads or on rough roads, they may require more frequent assessments, roughly every five to seven thousand miles. These checks may include the following:

- Axial and Radial Play: Any play too wide exceeding specified tolerances, which is often around five hundred microns, demonstrates noticeable wear, or worse, component failure.

- Boot Integrity: Any loss of grease through seals or torn seals denotes loss of effective lubrication, which may lead to excessive wear.

- Torque Values: Confirm the torque on the tie rod end fasteners with factory standards. Most passenger vehicles will fall in a general range of thirty five to fifty foot pounds; however, the service manual should confirm the torque values.

If these intervals are followed, optimal handling response is ensured, illustrating reduced risk towards premature failure within the suspension or steering systems.

Can tie rods be repaired or only replaced?

Rods are usually replaced instead of repaired due to their importance in the steering system’s line of action. Repairing a tie rod means it can no longer provide dependable structure control. Always recommend replacement once wear and damage or play goes beyond acceptable limits.

- Thread Participation: Check that threads have meshed well between the inner tie rod and steering rack, and the outer tie rod with the steering linkage. Check the service manual to get the right measurements.

- Torque Values: Fasteners should be tightened to factory-recommended values, which for most passenger vehicles is 35-50 ft-lbs; always check the service manual for the right values pertinent to the unit.

- Alignment: Carry out a wheel alignment post-replacement to restore mandated steering geometry and check if the rodding is out of alignment. If it’s not attended to, unevenly worn tires and poor handling may result.

Following these replacement practices ensures that the steering system works correctly within the desired scope of safety.

How are tie rod problems diagnosed?

What tests does a mechanic perform to check tie rods?

Overhead mechanics typically conduct a set procedure for diagnostics to ascertain the condition of the tire rods. The primary steps in diagnosing the condition of the rods are:

- Visual Inspection: Eyesight is also considered a diagnostic tool in the case of tie rods. The mechanic visually inspects the tie rod boots for cuts, cracks, or tears that may lead to contamination, as well as any abnormal accumulation of grease or dirt in the vicinity of the joint.

- Steering Play Test: Mechanic raises the vehicle and secures it using a hydraulic jack, then coaches the tire at both the ‘Three o’clock’ and ‘Nine o’clock’ positions. Presence of excess wiggle usually indicates a failing tie rod bearing or end.

- Pry Bar Test: The mechanic inserts a pry bar into the tie rod joint and plays it in different directions to apply different amounts of force into the joint in different rotations. Noticeable slack movement that exceeds normal boundaries is regarded as a joint that is about to fail.

- Wheel Alignment Check: The Mechanic evaluates the alignment of the front wheels relative to the steering column and calculates any deviation from a set of given angles. Mechanical components of the vehicle do experience relative degree changes regardless of the rotation motion of the wheels. Hence, in the event of a damaged or worn tie rod, a check is guaranteed to find distortion from the normal ankle that is set.

- Road Test: Mechanic drives the vehicle in order to evaluate the response of the steering wheel in relation to general behavior of the vehicle in movement. Any abnormal sound like grinding, excessive jerking while turning the wheel, or pulling the car one way or another hints on the possibility of tie rod failure.

Every test offers valuable information to guarantee precise diagnosis. Replacement is advisable to preserve steering control and safety if any looseness or play surpasses the limits set by the manufacturer.

Can tie rod issues be identified during routine maintenance?

Indeed, during regular servicing, tie rod issues can often be uncovered with appropriate attention to inspection and diagnostic procedures. During the routine check, the technician checks the tie rods visually for breakages like cracks and corrosion, as well as checking the worn protective grease boot seal. They also look for signs of slack within the tie-rod ends during suspension checks that normally involve applying a pry bar or physically moving parts to check against tight factory tolerances.

- Axial Play Tolerance: Most manufacturers have an allowance for movement of no more than half a millimeter through the center. Definite looseness indicates deterioration.

- Boot Integrity: Fractures, splits, or absent grease in the tire rod boot could mean a failure is likely through contamination or another internal component dried out.

- Torque Values: Connections like ball stud nuts have to be tightened to torque values; for example, between 40-60 Nm depending on the vehicle’s design. If these are not tightened properly, movement and consequent misalignment can ensue.

- Wheel Alignment Deviations: Deviations of toe angle beyond plus or minus zero point one two degrees may indicate problems with the tie rod or alignment.

Following these steps and observing the conditions enables early identification of potential tie rod issues without inflicting additional damage to the steering system, thus enhancing the overall safety of the vehicle.

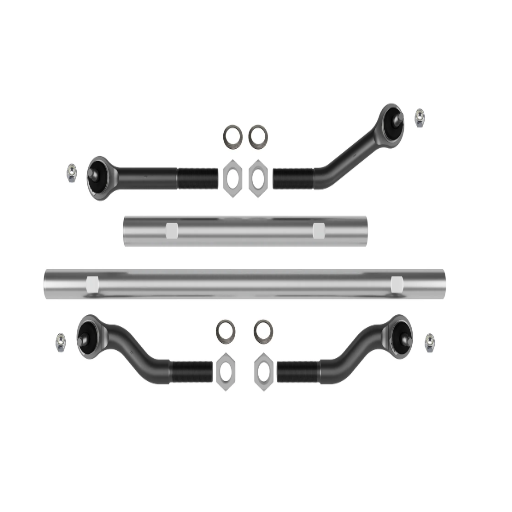

What’s the difference between inner and outer tie rods?

How do inner tie rods connect to the steering rack?

The inner tie rods are mechanically connected to the steering rack and directly impact the steering and outer tie rods. The outer tie rods are usually connected using a threaded ball joint, which provides the necessary angle of rotation for steering movements. The inner tie rod is attached to the steering rack by a thread, or a screw, fitting of some type, or the inner tie rod would rotate too freely rathe than translate rotation to steering force.

- Ball Joint Thread Diameter: Usually, due to the vehicle specification, between 12 mm and 16 mm for optimal strength under a load.

- Rotational Torque: It should be within a range of 2-6 Nm to facilitate movement of the joint with minimal friction at the joint but without so much slack that it is loose.

- Axial Force Endurance: The inner tie rod must take axial forces on the order of 25-50 kN, which is normal in very aggressive steering movements.

- Proper Lubrication: To avoid wear, high-quality grease with a temperate range from -40°C to +120°C will be required to enable smooth movement.

Accomplishing these guidelines and performing periodic checks enable the inner tie rods to sustain their best working conditions and life span within the steering system.

What is the function of outer tie rod ends?

The outer tie rod ends connect the steering knuckle to the inner tie rod and act as a link between the steering force and steering rack while the car is in motion. This part plays a pivotal role in the mobility of steering and balance between the front wheels. Due to the movement enabled by the outer tie rod end, propulsion can be utilized while simultaneously bolstering the mechanical connection and permitting the suspension system to operate unhindered.

- Ball Joint Stud Taper Angle: A stud is assumed to be having a taper angle in the range of 7 and 10 degrees. This angle permits the stud of the steering tie rod to snugly seat in the steering knuckle while in operation, preventing loosening with excessive vibration and load.

- Swing Angle: The suspension movement without binding could be estimated to be 20 – 40 degrees for the outer tie rod end to serve its purpose.

- Axial Load Capacity: When put to work, the part is assumed to work under certain forces from 15 to 30 kN, which means that it will still function under impacts and extreme steering actions, which is required from the component.

- Protective Boot Material: The dust-protecting boot in rubber or thermoplastic material must prevent infiltration of oil, water, and dust while operating and prevent such materials from -40 degrees to 125 degrees.

Through closely observing proper monitoring and lubrication, as well as adhering to the outer tie rod ends specifications, vehicle stability and steering operation will be significantly improved.

Frequently Asked Questions (FAQs)

Q: How do tie rods work in a car’s steering system?

A: Tie rods are crucial components of your car’s steering and suspension system. They connect the steering rack to the steering knuckles, allowing you to steer your vehicle. When you turn the steering wheel, the tie rods transmit the motion to the wheels, enabling them to turn left or right. Tie rods are used every time you steer, making them essential for safe and precise handling.

Q: What are the signs that a tie rod is bad?

A: Some common signs of a bad tie rod include uneven tire wear, steering wheel vibration, and loose or wandering steering. You may also hear clunking noises when turning or going over bumps. If you experience any of these symptoms, it’s important to have your tie rods inspected and replaced, if necessary, to maintain safe steering control.

Q: Can a broken tie rod cause an accident?

A: Yes, a broken tie rod can cause a serious accident. Without tie rods, you’ll lose the ability to control your vehicle’s direction. A sudden tire rod failure while driving can lead to a loss of steering control, potentially resulting in a collision. This is why regular inspection and maintenance of tie rods are crucial for vehicle safety.

Q: How often should tie rods be replaced?

A: The lifespan of a tie rod varies depending on driving conditions and vehicle usage. Generally, tie rods can last anywhere from 50,000 to 100,000 miles. However, it’s recommended to have them inspected during regular maintenance checks. If you notice any steering issues or uneven tire wear, it’s best to have them checked immediately, regardless of mileage.

Q: What causes tie rods to wear out?

A: Tie rods wear out due to constant use and exposure to road conditions. Factors that accelerate wear include rough roads, potholes, and frequent turning. Additionally, lack of lubrication, environmental factors like road salt, and manufacturing defects can contribute to premature tie rod wear. Regular inspections can help identify wear before it leads to failure.

Q: Can I drive with a bad tie rod?

A: It’s not recommended to drive with a bad tire rod. A bad tie rod can cause unpredictable steering, increased tire wear, and potentially lead to a complete loss of steering control. If you suspect a problem with your tire rods, it’s best to have your vehicle inspected by a professional mechanic as soon as possible to ensure your safety on the road.

Q: Can tie rods affect wheel alignment?

A: Yes, tie rods play a crucial role in wheel alignment. They not only help move the wheels left or right but also maintain proper toe alignment. Worn or damaged tie rods can cause misalignment, leading to uneven tire wear and poor handling. After replacing tire rods, a wheel alignment is necessary to ensure the steering geometry is correct and the vehicle tracks straight.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8