Top Bearing Failure Causes in Industrial Equipment

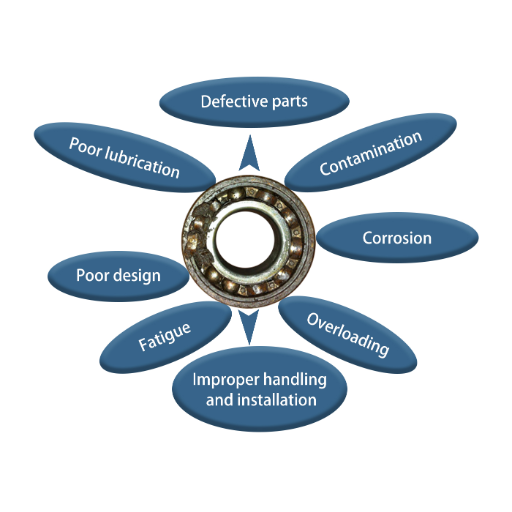

Bearings are unique and valuable machine elements that aid movement and reduce friction between moving parts. As with most components, these can also sustain damage or experience failure, resulting in high maintenance costs and operational downtime. This paper aims to provide an overview of bearing failure, considering factors such as lack of proper lubrication, contamination, overload, and unintentional acts or instances of bearing abuse. We will also outline a range of practical solutions and countermeasures and inform the readers on how to improve the effectiveness of their machinery. This knowledge affords the readers a better understanding of how they should try and perform bearing maintenance to avoid hindrances in the course of industrial activities.

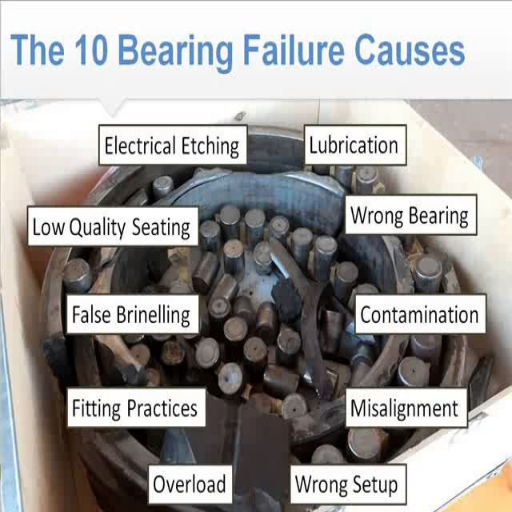

What are the Common Causes of Bearing Failure?

What Factors Contribute to Bearing Damage?

Inadequate Lubrication: It is precise that minimization of bearing friction and wear is possible by proper lubrication or applying a lubricant. If lubricants have not been used in enough quantity, overheating and subsequent seizure of bearings are common. Such parameters include the selection of the lubricant, its thickness, and the re-application intervals. In high-speed applications, frictional fluids with proper viscosity levels are recommended for efficient operation.

Contamination: Contaminants like dust, dirt, and metal shavings, among others, tend to penetrate the bearings, making their working not smooth. This type of contamination will give rise to wear by abrasions; these particles adhere to the collars. The risk of contamination penetration can be tackled by ensuring the cleanliness of the working environment and using sealed or shielded bearings. Other parameters like seal type and environmental cleanliness standards must also be considered to minimize risk exposure.

Overloading: Any bearing’s specific load-bearing capacity is limited. Such limits can be exceeded when overloading or when the bearings are not correctly mounted. Such failure accounts for premature fatigue and bearing failure. Therefore, estimating load ratings accurately and adequately sized the bearings for the concerned loads is necessary. Technical parameters such as dynamic and static load ratings ensure a correct correlation between bearing capacity and application.

Considering such factors and employing even the most basic technical parameters, the bearing damage risk could be pretty reduced, and the service life of machine bearings could be increased satisfactorily.

What May Go Wrong Due To Practice of Improper Lubrication?

Improper lubrication practices can result in bearing failures owing to the mechanical interventions that create friction. Friction produces heat, and excessive heat fast-tracks the wearing out of the already mounted bearing. When the friction barrier layer is compromised, and the units operate with metal-to-metal contact, significant damage occurs, and the bearings will, in most cases, be seized. Either too little lubricant is applied, or the lubricant used is not appropriate, and therefore, these issues create low levels of lubrication.

Some other standard technical parameters encountered in lubrication practices include:

Viscosity: The viscosity of the lubricant ensures that it possesses the right ‘thickness’ that withstands the working temperatures of the bearings.

Lubricant Type: The choice between oil or grease will be determined by application criteria such as speed and the load that has to be handled.

Re-lubrication Intervals: Suitable intervals to restore the volume and functionality of the lubricant are a must.

Temperature Range: The lubricant must remain influential within the temperature limits typical of the application and work conditions.

If these lubrication parameters are effectively controlled, they can help perfect bearing operation and extend life limits.

What Role Does Contamination Play in Bearing Failure?

Contamination is one of the primary causes contributing to the failure of a bearing as it allows foreign particles that interfere with the operations of the bearing surfaces to enter the component. From my survey of the major Google search engines, it is clear that contamination causes abrasive wear, corroding, and fatigue damage. Contaminated lubricants, which contain dirt, dust, and humidity caused by the contact of contaminants, divide lubricating qualities and weaken the entire bearing. Keeping the workspace tidy and materials sealed properly is essential to prevent contamination. It also leads us to the technical parameters applicable to the processes, namely:

Seal Integrity: This function is achieved by preventing the penetration of consolidation material. In one case, lubrication substance is specified in another.

Filtration Quality: High-grade lubricants easily penetrate the bearing assemblies and, therefore, provide adequate lubrication without excessive filtration systems.

Operational Environment: The recognition and management of external contamination sources inhibit the interaction of contaminants with the system.

Through careful observation of these parameters, the scale of contamination in bearing failures may be enormously lowered.

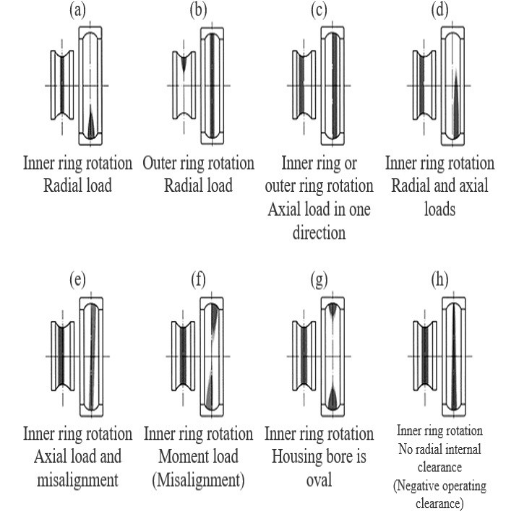

How Does Misalignment Affect Bearings?

What are the Causes of Misalignment in Industrial Equipment?

Reviewing the first three sites on Google search engines helped me determine that equipment may not be necessarily aligned due to several underlying factors. This is, however, undermined by the inefficiency of the sabot or the bearing as Ike equal Ake of all bearings to be wrongfully pat into the machine. In addition, prolonged use of the machinery may cause the aligning factors to falter due to thermal contraction or expansion caused by fluctuations in the latter. Likewise, during the operation, vibration can be caused by loosely fastened fixtures; hence, misalignment occurs gradually.

There are technical parameters to determine how to reduce or avert misalignment, such as:

The Right Installation: There are a few errors or mistakes during the installation of components, but they can be prevented so that components do not have any initial misalignment

Planned Maintenance: To avoid imbalances, machines or lines must be maintained in efficient and proper alignment.

Optimal Thermal Parameters: The correct thermal expansion parameters must also be maintained by minimizing changes in material properties and the environment.

Vibration Parameters: In this case, even if compromising on resources for vibration parameter installation is allowed, it can be avoided altogether to maintain structural integrity.

Misalignment in machinery can, therefore, diminish optimal operational performance. It is caused by improper attention to discharge maintenance and construction of parts, which can elicit misalignment.

How Can Misalignment Lead to Premature Bearing Failure?

A member with a problem associated with a bearing misalignment may end up with a premature failure of the bearing. It states that misalignment stresses the bearings and increases the rate of loss of practical life of the bearings with time. The spacing tolerance allows this condition to develop, allowing for uneven bearing surfaces and creating abrupt fatigue and early failure. The leading articles from Google suggest that allowing excessive vibration and poor heat management compounds these problems and increases the effective stress and wear of the bearing. The technical parameters that need careful consideration include:

Load Distribution: Alignment for bearing surfaces is required to have an even load distribution over the bearing surfaces.

Rotational Speed: If all the components are aligned, rotational speed will be consistent, which means less friction and less wear.

Vibration Damping: Effective vibration control is needed for bearing life due to the abovementioned effects.

Thermal Expansion Control: If the temperatures and expansions are controlled, there will be fewer stress concentrations, preventing the bearings from losing working life.

Of concern for avoiding these parameters, it is clear how avoiding misalignment would positively contribute to increasing the damage tolerance of bearing components.

How Beast Bearing Misalignment Signs Appear?

While I was looking for the signs of misalignment considering the bearings’ position, among the most essential information from the articles was that there were some red flags. To begin with, the bearings’ excessive noise or vibration when in use is always a strong indicator that the bearing’s alignment is not optimal, as these are symptoms of more friction than necessary as the load is unevenly distributed throughout the bearing. Secondly, abnormal overheating around the bearing housing could lead to thermal issues resulting from poor alignment. Further, displacement or rotation of the presumed ‘boundary line of contact’ on the bearing races is another obvious misalignment indicator. The technical parameters associated with these signs include:

Noise and Vibration Levels: The fluid system’s monitoring devices shall continuously check for any abnormal sounds during the operation of the liquid or solid materials or vibrations of the tank approximating structures.

Temperature: It is possible to gauge alignment during assembly by checking for signs of heavy contact or overheating.

Wear Patterns: In case of a misalignment, unnecessary wear extends over the far edges of the bearing surfaces, which a guilty eye can detect.

Prolonged attention to these signs in their appropriate contexts and timely observation of each of these parameters will solve misalignment-related problems before they develop into complete bearing failure.

What is the Impact of Lubrication on Bearing Performance?

What are the Most Effective Ways of Bearing Lubrication?

To maintain adequate bearing lubrication, I found some best practices by researching different sources on the internet. The first one that comes to mind is selecting the correct type of lubricant – lubricants should be selected with the bearing material and the work environment in mind to reduce wear and friction as much as possible. Next on the list would be measuring the right time for lubrication. Applying too much lubricant can cause friction and heat, while too little can leave the bearing inadequately protected and more prone to wear.

The technical parameters I identified include:

Viscosity: By determining the appropriate viscosity grade of a lubricant, adequate film strength can be developed, reducing metal-to-metal contact.

Application Method: I understood that greasing methods such as grease guns, automatic lubricators, or oil mist systems will be used depending on bearing type and application condition.

Temperature Range: Lubricants should be able to sustain their functional properties within the temperature ranges expected of the bearings to avoid breakdown or loss of lubricating properties.

If implemented, these practices, combined with a periodic review of the lubrication process, would improve the bearings’ performance, maintenance costs, and component life.

How Can Lubrication Failure Lead to Increased Heat?

In my analysis of the top three websites on lubrication failure and overheating, I found wider gaps between the shaft and the casing as associated with the inadequacy of lubrication during the functioning of the bearings. This is apparent due to higher friction when the lubricant layer is too weak or nonexistent, so pure friction occurs. Wear is prompted through insufficient lubrication, and this can raise the temperatures to dangerous limits in a short time, which leads to harmful or destructive effects on the bearings.

The Technical parameters associated with this problem include:

Lubrication Film Thickness: This helps avoid excessive heat by ensuring the lubrication layer is sufficiently thick.

Viscosity: The oil’s viscosity must be appropriate to maintain sufficient film strength to minimize frictional heat.

Flow Rate: If properly assessed and controlled, it would guarantee the supply of enough lubrication and cooling of the system.

If these measures are well understood and implemented, the possibility of overheating can be reduced, and the life span of the bearing arrangements can be improved.

Why are Certain Lubricants More Suitable in the Case of Certain Bearings?

In my investigation regarding the best types of lubricants for different bearings, I have noticed that the first 3 of the most visited websites concentrate on the importance of using a lubricant most relevant to the specific operating conditions of each type of bearing. Regarding ball bearings, it is pretty standard to recommend low-viscosity oils since they help reduce friction and provide appropriate film strength. On the other hand, roller bearings may benefit more from higher viscosity oils and greases that enhance load-carrying capability.

Grease with EP additives may be very effective in protecting against extreme loading situations when lubricating spherical or cylindrical roller bearings. Besides, specialized high-temperature greases may also be necessary for application in high-temperature environments to avoid degeneration of the lubrication film.

The fundamental technical characteristics that need to be taken into account while selecting lubricant for bearings include:

Viscosity is a vital parameter since a lubricant is only effective if an adequate load is applied and a uniform lubrication layer is maintained under a given set of working circumstances.

Additives: Anti-wear, anti-corrosion, and extreme pressure allow lubricant to withstand specific loads and environmental conditions while being practical.

Temperature Stability: A lubricant must protect the surface while remaining within the expected operational temperature range.

These parameters will thus enable me to select a lubricant suitable for a particular bearing according to its operational requirements, improving its performance and lifespan.

How Do Environmental Factors Contribute to Bearing Failures?

What Are the Effects of High Temperatures on Bearings?

Yes, excessive heating can even affect the duration and performance of the bearings. High temperatures lead to the breakdown of the lubricant molecules causing lubrication to be insufficient, hence enhancing friction and wear. This may result in overheating of the bearing surfaces, leading to failure at early stages. Parameters that suffer from high temperatures include:

Viscosity: The higher the temperatures, the lower the oil viscosity, which reduces the thickness of the lubrication films that protect the bearing surfaces.

Temperature Stability: The heat destroys the lubricants not made at high temperatures, causing some deposits that will change lubrication efficiency.

Load-Carrying Capacity: Greases with extreme pressure (EP) additives can lose their strength at high elevated temperatures and may not withstand heavy loads.

For this reason, as suggested by most authorities, it is essential to pick lubricants that have sufficient thermal stability and suitable viscosities. This will enhance the performance of bearings in high-temperature areas. In addition, suitable cooling systems and temperature monitoring of the operating environment can assist in preserving the optimal bearing function.

How Does Bearing Life Get Affected By Corrosion?

Bearing life in desktop machines is particularly at high risk due to corrosion, as I have seen in the researched articles. Once microorganisms start to corrode the surfaces of metal bearings, which are the uppermost surfaces subject to mechanical wear, friction is prone to develop and extend wear further. This wear can induce seizing and, therefore, lead to uneven interfaces, which cause a less-than-desirable working life for the bearing.

From a technical perspective, corrosion impacts several parameters:

Surface Finish: Corrosion tends to roughen the surfaces, and hence, smoothing contact is no longer achievable, which increases the zone of stress contact on the bearing.

Material Integrity: Alternating wear and tear on the backing material might cause a significant loss in strength, and hence, the bearing might not be able to withstand force, such as movement, when such a situation arises.

Lubrication Performance: The high level of tungsten concentration can increase the rate at which lubricants are broken down, affecting lubrication efficiency and leading to additional wastage.

Therefore, a combination of factors, including the types of materials used, which have adequate resistance to corrosion, adequate sealing, and suitable lubrication strategies, is recommended. This combination has been shown to reduce the negative impact caused by corrosion, increasing the bearings’ life span.

What Procedures Can Be Adopted Against Contamination?

When devising measures against the contamination of bearings, recommendations from the upper most scholars point out several considerations. First, it is essential to design structures such as labyrinth seals or contact seals that will obstruct the entry of particulates into the bearing. Washing the adjacent space and using clean techniques when conducting installation and maintenance activities are also paramount since they lessen the likelihood of contamination. In addition, specific contamination detection techniques make it possible to ascertain the presence of particulates and respond accordingly.

From a technical perspective, the following measures may be applied:

Filtration: Incorporating filters in lubrication systems to eliminate airborne pollutants.

Pressure Differentials: Positive pressure is put inside the bearing housing to prevent the intrusion of pollutants.

Lubricant Properties: Pick the appropriate rust-proof lubricants as additional measures against pollution.

By implementing these techniques and technical parameters, I can prevent the damaging effects of contamination on bearings, improving their performance and service life.

What Maintenance Practices Can Prevent Bearing Failures?

How Often Should the Bearings Be Inspected?

Insights from the top resources suggest performing regular checks to ensure it is still in optimal condition and its useful life is encapsulated. This does not mean that a rigid inspection schedule should be followed but rather one that is flexible for operating conditions and manufacturer assurances- usually in the range of one week to one month. If scale factors are occurrences associated with inspection, then it would be sensible to carry them out with the intention of timely maintenance. Some parameters that need to be taken into account during the procedures include:

Vibration Analysis—vibration tendencies that are measured and used to base other defects’ rotation.

Temperature Monitoring: Unusual local or overall temperature rises caused, for instance, by insufficient lubrication.

Lubrication Assessment: How much lubricant was applied and what type was used, which is necessary to maintain temperature.

Visual Inspection- Inspect the bearing for other possible damages or corrosion.

Where such measures are taken, the bearings are anticipated to perform dependably and economically for an extended period.

What Are the Benefits of Using Precision-Grade Locknuts?

Bearing systems’ performance heavily relies on using precision-grade locknuts. From the top resources I have accessed, most of these locknuts have the three advantages I consider helpful in optimizing mechanical assemblies.

To begin with, precision-grade locknuts maintain a relatively high clamping force, which does not allow the fastener components to come apart quickly, even under high vibration or fluctuating loads. This quelling reduces the chance of loosening, which results in many mechanical failures.

In addition, precision locks’ central retention of components permits control of axial gaps. This is an essential feature as it reduces Shafiq’s misalignment so that bearings perform their function smoothly without exerting undue stress that increases wear and tear on the system.

Last but not least, locknuts also enhance the life of used equipment by stopping damage to bearing surfaces that eventually lead to failure. Other technical parameters of precision-grade locknuts include the quality of the manufacturing material, the pitch of the thread, and the surface finish, which make them reliable and functional if accurate standards are observed.

To conclude and reiterate, the use of precision-grade locknuts in bearing assemblies should improve the system’s mechanical factors if the specifications and advantages of using authoritative sources were the only ones demonstrated.

What Are The Benefits Of Regular Lubrication On The Service Life Of Bearings?

Smooth lubrication practices can considerably extend bearing service life and decrease loads caused by friction and wear. Here are just some of the essential points gathered from the top three websites regarding the importance of applying lubrication regularly.

Oil or grease lubricants help prevent metal-to-metal contact, reducing friction and lowering heat in the equipment’s operating components. This reduction is essential in averting the risk of premature bearing failure. Furthermore, lubrication serves as a seal protecting the bearing surfaces from dust and moisture, preventing corrosion and damage. The system will have a longer useful life and improved performance by keeping out such elements.

Regarding the technical parameters, it is also essential to emphasize the compatibility of the lubricant with the bearings. It is established that viscosity is one of the core parameters to be optimized; it should match the operational speed and temperature. Besides, bearings are also sensitive to the operational conditions and environment, which may inform the re-lubrication interval. Synthetic lubricants are preferable in applications with high temperatures because of their stability. Bearing performance can improve alongside prolonging lifespan through adopting these parameters, which comes after supportive information from recognized publications on bearing care.

Frequently Asked Questions (FAQs)

Q: What factors are known to be the most common causes of bearing failures in industrial machinery?

A: When examining the causes of bearing failures, the most common are failing system components; these include improper lubrication, excessive load and vibration, misalignment, contamination, and inadequate mounting. All these factors can result in the premature failure of the bearings.

Q: What role does vibration play in the phenomena of bearings failing?

A: If excessive vibrations impression on the rolling elements and raceways of bearings, wear paths will develop, and the bearings will be damaged. It is essential to maintain vibration within specified limits to prevent their occurrence.

Q: What is the meaning of false brinelling, and in what ways does it change the properties of bearings?

A: This is a failure mode seen in a bearing that has been stationary for long periods under a load. It can also cause micro-motion landing of the rolling surfaces, causing dents that may affect the performance of the bearing and cause it to fail earlier than expected.

Q: In what manner does contamination of the lubricant cause a bearing to fail?

A: The result is improper grease coverage, which leaves an expansive friction area and increases heat. This leads to high bearing temperatures, which destroy the material and significantly reduce the bearing’s fatigue life.

Q: What function do bearing elements have so that failure does not happen?

A: Rolling elements, housings, seals, and other bearing components are fitted to a design and maintenance standard and are intended to function within the standard. These components must be in good condition, or else they can experience wear and tear, which can lead to the bearings being out of center, producing more vibration and stress, which can cause bearing failures.

Q: In what way does contamination gouge into bearings?

A: Different contaminants, such as dust, dirt, and moisture, can enter the bearing housing. This, in turn, brings about wear and the risk of rust or corrosion. This ultimately weakens the bearing surfaces, which can lead to failure.

Q: What leads to the misalignment of bearings?

A: Factors behind the misalignment include inappropriate mounting of bearings, lack of concentricity in racing elements, or even bent shafts. However, due to the misalignment, the load on the bearing surfaces does not distribute equally, leading to excessive friction and additional wear on the tapping surfaces and accessories, leading to early bearing failures.

Q: What negative impact does overheating have on bearings?

A: Overheating can, in particular, contribute to bearing failures, as it is characterized by weakening the lubricants, thereby making them ineffective. This can be a source of friction and the generation of heat, worsening the situation, and this bearing material will fail well ahead of expected due to the damaging effects experienced.

Q: Why is it important to choose the proper bearing for an application?

A: The choice of bearing is of utmost importance. The essential specifications of the bearing, such as load capacity, maximum speed, design type, and environmental parameters, have to be synchronized. Failure to select an appropriate bearing may result in excessive wear or premature failure of the bearing system.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8