True or False: Lubrication is the Use of Oil and Grease to Increase Friction?

Lubrication is a fundamental process widely utilized in engineering, industrial applications, and mechanical systems to enhance efficiency and prolong the lifespan of components. Despite its ubiquitous role, there are many misconceptions about lubrication, including its purpose and how it interacts with surfaces in motion. This article seeks to clarify key concepts surrounding lubrication, including its mechanisms, applications, and common misunderstandings. By addressing this question—whether lubrication increases friction or not—and systematically exploring related topics, readers will gain a detailed understanding of lubrication’s critical function in reducing wear and optimizing performance in machinery and everyday operations.

What is the primary purpose of lubrication?

Understanding the role of lubricants in reducing friction

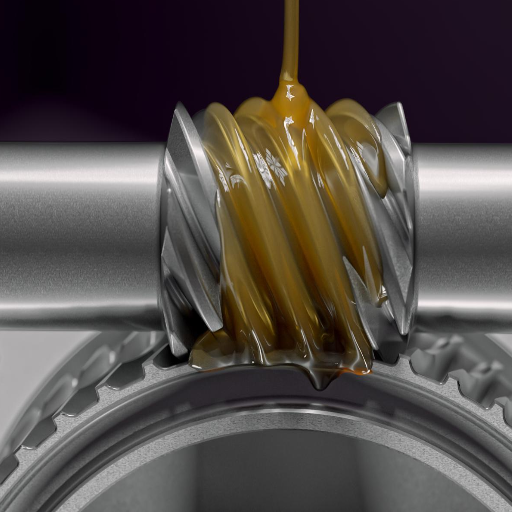

Lubricants minimize frictional forces by creating a barrier between two interacting moving surfaces. This barrier acts to limit contact between two surfaces and thus, lowers the force of friction, leading to less wear and tear. Lubricants manage this through two principal methods; in hydrodynamic lubrication, a continuous film or fluid separates the surfaces, while boundary lubrication uses chemical components that form a film under high pressure.

- Viscosity oil: Directly correlates with lubricant flow and its ability to maintain a film. Computer-controlled viscosity measuring devices indicate a range of 10 – 400 cSt at 40°C for most industrial applications.

- Coefficient of Friction: Coming back to lubricated systems, CoF is maintained in the vicinity of 0.001 – 0.1 from typical values in unlubricated over the surface contact of ~ 0.3 to 0.6.

- Load Bearing Index: Points out the maximum load that the lubricant can bear at a film-preserved condition without disintegration, expressed as N/mm².

- Operating Temperature Ranges: Identifies the ranges that the lubricant is acceptable at. For example, Multi-grade oils have reasonable ranges of -30°C to 150°C.

- Additives: Such as anti-wear agents, extreme pressure (EP) additives, and corrosion inhibitors, are designed to facilitate enhanced performance of the lubricant.

These technical requirements must be achieved if machinery is to attain maximum performance and eliminate all possible faults while protecting the surface.

How lubrication works to minimize wear and tear

Lubrication lessens wear and tear by direct contact and friction among moving parts. It does so by placing a protective layer which results in minimal contact between moving parts which also results in lesser friction. Much less heat is produced, in addition to great news for how long a component of the machine can work.

- Viscosity: Ensures the lubricant forms a stable film under operating loads and speeds, preventing surface contact.

- Operating Temperature Range: Predetermined temperature ranges where a lubricant remains fluid and stable within the machinery’s conditions. For example, -30°C to 150°C for multi-grade oils.

- Additive Content: The olive oil-like substances that come with anti-wear agents, and extreme pressure (EP) additives allow surface protection in extreme conditions.

Taking these factors into consideration can determine the reliability and efficiency of lubrication. Matching the factors with the machine’s operational requirements leads to a reduction in mechanical degradation and downtime.

The relationship between lubrication and machinery lifespan

The lubrication of any mechanical system greatly affects its life due to its effectiveness in reducing wear, dissipating heat, and minimizing friction. A correctly applied lubricant ensures the formation of a protective layer between friction surfaces which limits their metal contact and avoids surface erosion from abrasive or adhesive wear. On the other hand, inadequate or improper lubrication aggravates pitting, scoring, and rusting, which can lead to equipment failure in the long run.

- Viscosity: The lubricant should match the viscosity rating that is appropriate for the machine’s operating conditions. A case in point is high-speed mechanisms that are often fitted with low-viscosity lubricants to minimize resistance, while high-load conditions operate with ease because of high-viscosity lubricants.

- Viscosity Index (VI): A high VI value drives reliability in extreme temperature environments, and thus guarantees dependable performance when it is either too hot or too cold.

- Flash Point and Pour Point: These determine the lubricant’s working range. A low pour point ensures flowability in cold temperatures while a high flash point arrests degradation at elevated temperatures.

- Load Carrying Capacity: Extreme pressure (EP) additives improve the lubricant’s ability to handle greater loads and protect the machine parts from stress.

Using the appropriate lubricant and following a scheduled maintenance plan is important in averting mechanical wear and tear. Regularly conducted condition monitoring along with these factors guarantees the machine performs at its best, experiences minimal downtimes, and has a long service life.

How does lubrication affect friction between moving parts?

The science behind friction reduction through lubrication

Essentially, lubrication reduces the contact area of two moving bodies, which in turn lowers frictional forces hence, heat generated during motion is eliminated. To some extent, lubrication effectiveness is determined by several important technical aspects, such as:

- Viscosity: The flow resistance of the lubricant as measured in centistokes (cSt) indicates the thickness of the protective film. Slower-moving parts that experience heavy loads require lubricants with a higher viscosity to maintain adequate lubrication whilst high-speed applications demand lower viscosity lubricants.

- Friction Coefficient (μ): Good lubrication can reduce the friction coefficient between two surfaces from normal dry contact values (~0.5-1.0) downwards to ~0.001-0.1 depending on the lubricant type, purpose, and application.

- Load Capacity: The operational loads to be borne have to be done without rupturing the lubricant. This is quantified by EP (extreme pressure) ratings or load-wear indices of base oils or some additives.

- Temperature Stability: Lubricants have to remain stable in their intended operating temperatures which usually range from -20°F to +500°F depending on the application. Some lubricants undergo thermal degradation at higher temperatures compromising their functions.

- Shear Strength: The lubricant should not undergo molecular breakdown due to mechanical stress therefore the resultant layer should be strong enough to withstand intense dynamic conditions.

lubrication improves contact mechanics, minimizes wear, maximizes energy efficiency, and improves operational performance. All of this automatically makes lubrication critical in dealing with friction in machine systems.

Comparing static and kinetic friction in lubricated systems

In the context of lubricated systems, the distinction between the two forms of friction, static and kinetic, lies in the resistance force before and during motion. Static friction is understood as the resistance that has to be overcome to perform the first position change between two surfaces. As it is, it will always be higher than the kinetic friction because the primary asperity contacts, i.e. the interlocking surface roughness, within the material remains bonded. On the contrary, kinetic friction is the one that exists in movement and works to decrease because surface interactions (roughness) are being interfered with by the lubrication. In engineering terms, the coefficients related to static and kinetic friction, μs and μk, respectively, are of utmost importance.

- Coefficient of Static Friction (μs): This is higher in most cases because the lubricant requires a certain amount of shear stress to break the adhesion bond that is present on contact points.

- Coefficient of Kinetic Friction (μk): This is lower in most cases since the lubricant film works to allow for smoother motion without much physical engagement of the surface rough portion to each other thus providing boundary lubrication.

Static friction often dominates when initiating motion, but kinetic friction steadily declines due to lubricant efficacy and system dynamics. Addressing these differences plays an essential role in optimizing industrial machine design and energy efficiency.

The impact of viscosity on lubrication effectiveness

The effectiveness of lubrication is determined by viscosity, which directly affects the ability of the lubricant to form a stable film under different surfaces. High-viscosity lubricants make it possible to obtain a thick lubricant film. While these can enhance the protection against wear on the equipment in high-load or low-speed applications, they may increase drag and energy consumption. Conversely, low-viscosity lubricants can have a reduction in frictional losses in high-speed operations but are inadequate for heavy loads that require sufficient film thickness.

- Viscosity Index (VI): Indicates how much the viscosity changes about temperature. A high unitless number index ensures stable performance in chilling and extreme thermal conditions.

- Operating Temperature Range: Estimates the optimal system temperatures that are optimal for effective lubricant viscosity.

- Shear Stability: Measures the lubricant’s resistance against mechanical stress which is imperative for consistent film strength and viscosity.

- Load-Carrying Capacity: Thicker film lubricants will have an increase in load ratings due to the viscosity needed to make the necessary film thickness.

By analyzing the specific application requirements, the optimal lubricating oil in viscosity can be selected to improve energy efficiency and system reliability.

What are the common types of lubricants used in machinery?

Oil-based lubricants: properties and applications

Oil-based lubricants have stood out among others, which enables them to win wide acceptance for use in machines and their parts owing to the multifarious range of uses that they can handle as well as being effective for lubrication purposes. These lubricants usually contain mineral oils, synthetic oils, or oils derived from biological sources, each of which possesses certain benefits depending on the intended use. For example, crude oil-derived mineral oils are inexpensive and suited for multifunctional general purposes. On the other hand, precision-engineered synthetic oils are the best choice for applications with high thermal stability and low-temperature fluidity requirements. Lastly, bio-based oils serve as a lubricant substitute which is friendly to the environment and still has suitable lubricating capabilities.

- Viscosity Index (VI): A higher VI guarantees a wider temperature range while ensuring optimal lubricant performance.

- Thermal Stability: At high temperatures, synthetic oils usually sustain oxidation and thermal breakdown better than other oils.

- Pour Point: Low pour points critically allow for use in cold operations, and these may be achieved using a selected mineral or synthetic oils.

- Additive Compatibility: Both synthetic and mineral oils can be modified to suit certain specifications by the addition of anti-wear, anti-oxidants, and corrosion inhibitor additives.

- Biodegradability: Bio-based oils are formulated such that they break down quickly in nature and thus do not pose a negative impact on the environment while maintaining efficiency.

An assessment of relevant operating requirements – temperature, load, and the existing environment – helps to select the best type of oil-based lubricant that will enhance the productivity and life span of the machines.

Grease-based lubricants: when and where to use them

Grease-based lubricants have a distinct advantage in situations requiring long-lasting lubrication and firm adherence to surfaces. Such lubricants can be used in areas where it is difficult to reapply the lubricant, such as sealed or hard-to-reach components. Some examples are automobile, industrial, and heavy machinery bearings, gears, and joints.

- Consistency (NLGI Grade): The National Lubricating Grease Institute (NLGI) considers grease consistency to range between 000 (to describe a fluid) to 6 (to describe a very hard material). NLGI Grade 2, for example, is generally used in sliding surfaces like bearings.

- Operating Temperature Range: Grease must above all be appropriate for the application temperature environment. Considering the execution of works at elevated temperatures, it is suggested to use synthetic or lithium-complex greases with a temperature limit of 200 degrees centigrade.

- Load-Carrying Capacity: Grease performance under high loads is improved with Extreme Pressure (EP) additives. Greases with EP additives are best suited for heavy-duty machinery.

- Water Resistance: Water, or in some cases corrosive media, requires grease with high water washout resistance, in which case calcium sulfonate-based grease is advantageous.

The proper grease selection ensures lower wear rates, greater reliability, and a longer lifespan of the equipment under certain operating conditions. This is normally the case for critical systems and moving parts that require precise lubrication; therefore, grease is one of the most important lubricants when it comes to devices that require high strength and stability.

Specialized lubricants for specific industrial needs

For certain industrial applications, selecting a specialized lubricant tailored to the operating environment is critical to achieving maximum performance and life. For instance, lubricants used in high-temperature environments are required to possess good thermal stability in addition to oxidation resistance. In such cases, a synthetic grease with polyurea or lithium-complex thickener is often employed as it can be used undeteriorated at working temperatures of 150 0C to 2000C.

Under extreme pressure (EP) conditions, greases with molybdenum disulfide (MoS2) additives or other EP additives are recommended. They help in decreasing friction and wearing at high-load situations, where typical bearing unit load ratings already in the four-ball wear test are above 4000 N.

In the case of processing food, an NSF H1 food-grade lubricant is required, proofing food safety where contact with food is unavoidable. Food-grade lubricants usually have thickener aluminum complex or calcium sulfonate and oils of higher grade to satisfy FDA and USDA rules.

Lastly, greases for machines that are subjected to water, salt spray, or other corrosive conditions are best made with calcium sulfonate where high water resistance and water corrosion inhibition are required. Such greases are said to perform best at rates of high water spray-off. Without more than a 5% loss In D4049 tes,t these greases perform well at a high water spray-off rate.

Can lubrication ever be used to increase friction?

Situations where increased friction might be desirable

The purpose of lubrication is mainly to mitigate friction, however, it can also be applied in certain ways that increase friction. Braking systems are one example where brakes and certain units use lubricant or grease that increases the friction between two parts for improved force control and efficient stopping power. Clutches or belt-driven systems are other instances whereby slippage and systems integrity can be maintained at optimized friction levels through proper lubricant choice.

- COF: The desired amount of friction depends on the pairing of materials and the conditions in which these materials operate. Clutch engagement is operationally sensible when the COF ranges between 0.3 and 0.5.

- Lubricant Viscosity: Friction and the heat that is produced need to be mitigated simultaneously, and, therefore, a particular viscosity range (ISO VG 32-46) is essential.

- Thermal Stability: Friction-based systems need lubricants that are stable at elevated temperatures, some are stable at 200-300°C

- Additive Formulations: Certain interactions require the inclusion of solid lubricants in the form of friction modifiers such as molybdenum disulfide for effective tailoring.

Such cases and systems whereby specific increases in friction must be met call for selection of the lubricants with these properties.

Alternative methods for increasing friction in mechanical systems

There are various ways to increase the friction of a mechanical system. All of these ways depend on the unique application and the system’s required friction characteristics.

- Surface Texturing: Friction can be increased by metal or thermoplastic texturing through laser texturing or deliberate abrasion. This is exceptionally beneficial for metal-on-metal and polymer-on-metal systems because it increases surface roughness. Some aspects to note are ideal roughness values (Ra), which depend on the material. Roughness value Ra ranges that need to be taken into consideration is 1 to 3 micrometers.

- Material Selection: To increase friction, one of the easiest methods is simply using materials with high inherent COF values. Rubber has COF values higher than 1 when in dry conditions. This means, that when rubber is placed on mating surfaces, it generates significantly more traction. However, the material used needs to be wear-resistant and thermally tolerant.

- Coatings and Surface Treatments: Using diamond-like carbon coatings or ceramic using a plasma spray delves into surface adhesion and grip. Therefore, these two coatings can be used to improve the surface of devices that are not under extreme conditions. On the other hand, devices that are under extreme conditions should utilize tungsten carbide-based coatings. These coatings offer high resistance to both friction and wear.

- Load Optimization: By the principles of physics, increasing the normal load makes contact points along the point of friction more forceful, therefore increasing the friction force.

There are trade-offs to consider regarding surface abrasion and system mechanical stability in employing this approach. Any such process should always consider the boundary conditions of the system such as temperature, load during operation, and the expected life cycle of wear to maximize performance while minimizing damage or inefficiencies.

What is the importance of proper lubrication in vehicles?

Key components requiring lubrication in a vehicle

- Engine: Moving parts of an engine need oil to streamline friction. This ensures that there is no excessive wear, overheating, and even breakage. An important factor to keep in mind is the viscosity of the oil which is rated in SAE (for instance, SAE 5W-30). A vehicle can operate effortlessly with the aid of properly meshed temperatures.

- Transmission: Both automatic and manual transmission systems require specific lubricants to facilitate easier gear shifts and remove excess heat. Other important factors include thermal viscosity index and stability.

- Differential: Differentials consume a great amount of gear oil due to high load as well as power transmission effectiveness. Commonly used specifications comprise API GL-4 or GL-5-rated oils. The main basis is the type of load and gears.

- Wheel Bearings: Protection from dirt and water can be preserved with grease lubrication which acts as a shield for rolling friction. Lithium-based greases are commonly used because of their capabilities under extensive temperatures which makes them a favorable option.

- Steering and Suspension Systems: The steering and suspension systems require grease that enables the movement of a load without causing wear. Elements such as tie rods and ball joints tend to reach a degree of friction within the bearing, so greasing in these components becomes crucial.

The incorporation of MoS2 in grease is popular because of its exceptional capability to withstand heavy loads and endure extreme pressure conditions. The appropriate lubrication of these parts is of utmost importance to increase the durability and functioning of the vehicle. Following the manufacturer’s detailed specifications is crucial for optimal performance as well as safety requirements.

How lubrication affects a vehicle’s performance and longevity

The efficiency and life span of a vehicle highly depend on how well it is lubricated. Lubrication reduces friction, wearing out parts, and helps keep the vehicle’s components free of dangerous contaminants and corrosion. The lubrication of the vehicle also promotes energy efficiency, smooths out any mechanical functions, and improves its lifespan.

- Viscosity: The viscosity of lubricants should be according to the manufacturer’s recommendations regarding film strength during an elevation in balance and temperature, elevation, and mechanical load. Automotive engine oils will use multi-grade ratings like SAE 5W-30 to strike the needed low and high-temperature balance.

- Load-Carrying Capacity: It’s crucial the greases and oils can withstand the operating load without breaking down. For example, gear oils API GL-4 or GL-5 are frequently used for high-grade environments in transmissions and differentials.

- Temperature Range: Lubricants must maintain performance under operating conditions, with synthetic options often preferred for extreme environments. As an example, synthetic engine oils can perform in temperatures as low as negative forty degrees Fahrenheit to those above three hundred degrees Fahrenheit (negative forty degrees Celsius to above one hundred and fifty degrees Celsius).

- Contaminant Protection: Particles such as dust and water that could potentially compromise the integrity of the system can be kept out by lubricants. These lubricants, enhanced with detergent and dispersants, also add to the cleanliness of the engine.

When implemented lubricants and oils do not stray from the vehicle’s technical rational limits while also improving the vehicle’s reliability envelope will reduce the spend on maintenance and improve the intervals within services further improving the sustainability of the vehicle.

Frequently Asked Questions (FAQs)

Q: Is the statement “Lubrication is the use of oil and grease to increase friction” true or false?

A: False. Lubrication is the use of oil and grease to reduce friction between moving parts, not increase it. This is a fundamental concept in tribology, the study of friction, wear, and lubrication.

Q: What is the primary purpose of lubrication in mechanical systems?

A: The primary purpose of lubrication is to reduce friction between moving parts. By applying a thin layer of oil or grease, lubrication plays a crucial role in minimizing wear, heat generation, and energy loss in mechanical systems.

Q: How does lubrication affect friction in a vehicle’s moving parts?

A: Lubrication significantly reduces friction in a vehicle’s moving parts. It creates a thin film between surfaces, allowing them to slide more easily against each other, which results in smoother operation, less wear, and improved efficiency.

Q: What is tribology and how does it relate to lubrication?

A: Tribology is the science of friction, wear, and lubrication. It studies the interaction between surfaces in relative motion. Lubrication is a key aspect of tribology, as it’s one of the primary methods used to control friction and wear in mechanical systems.

Q: Can you explain the difference between oil and grease in lubrication?

A: Oil and grease are both used for lubrication, but they have different properties. Oil is a liquid lubricant that flows easily and is often used in high-speed applications. Grease is a semi-solid lubricant made by adding a thickening agent to oil, making it ideal for applications where oil might drip away.

Q: How does the viscosity of a lubricant affect its performance?

A: Viscosity, which is a measure of a fluid’s resistance to flow, greatly affects a lubricant’s performance. Higher viscosity lubricants provide better separation between surfaces but may increase energy consumption. Lower-viscosity lubricants reduce energy loss but may not provide adequate protection in high-pressure situations.

Q: Are there any situations where increasing friction might be desirable?

A: Yes, there are situations where increasing friction is desirable. For example, in brake systems, clutches, and tires, higher friction is crucial for proper functionality and safety. However, these applications typically don’t involve lubrication in the traditional sense.

Q: How has the field of tribology contributed to energy efficiency?

A: Tribology has significantly contributed to energy efficiency by developing advanced lubricants and surface technologies that reduce friction and wear. This has led to improvements in fuel efficiency in vehicles, increased lifespan of machinery, and overall reduction in energy consumption across various industries.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8