Understanding ABEC 9 vs ABEC 7: A Comprehensive Guide

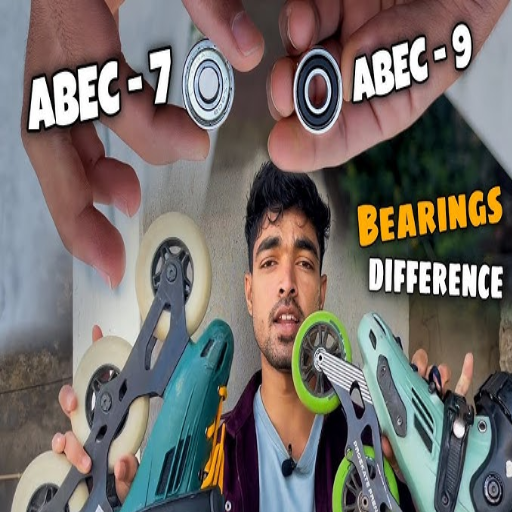

The rapidly growing popularity of skateboarding, as with any sporting activity, tends to create a higher demand for its sporting equipment. Of the many parts of a skateboard, one of its main elements is the bearings, as they significantly affect the velocity and fluidity of the board’s motion. During their active pursuits in skateboarding, however, most of them come across a baffling rating scheme relating to the different types of skate bearings, mostly ABEC 9 and ABEC 7. Firstly, this article aims to explain the ambiguity surrounding these two ratings, which are so often used, and their bearings, focusing on what difference the ratings make and which would be better for certain types of skateboarding. Therefore, it allows for the elimination of the frustration that comes with shopping for bearings by eliminating confusion caused by ABEC ratings and their peculiarities. The information being provided is not only beneficial for advanced skateboarders but also for beginners in this sport.

What is the ABEC Rating System?

How does the ABEC scale work?

The ABEC scale (Annular Bearing Engineering Committee) is widely used to measure the scales’ accuracy and the skateboard bearings’ performance. It’s sort of like a grade that highlights the tolerances and quality level put in the manufacturing process of the bearings, with many ratings specified in odd numbers: 1, 3, 5, 7, 9. The higher the number, the tighter the tolerances of a given bearing, which means it was built more precisely or with a higher grade. As such, the bearing will be smoother and faster, or at least potentially.

Technical specifications of the ABEC scale scale:

ABEC 1: This is the lowest precision rating and can be found with cheap bearings. Under low-quality use, they might work for quite some speed, but the bearings’ tolerances will be poor.

ABEC 3: These are still low precision rated bearings but found to have slight variation in precision and thus provide a fair value, which is why low-end skateboards are often used.

ABEC 5: Such a rating gets the most average precision bearings; however, these are the most common, as they are used for many skateboarding activities. They compromise the price with some performance.

ABEC 7: This is for the higher precision, efficient, and more expensive bearings used for smooth rides.

ABEC 9: The highest scale rating where bearings are meant for extreme high-speed usages, sometimes too high compared to casual skateboarding use.

The ABEC rating should be understood because it does not account for material, lubrication, or load capacities, which also significantly impact performance. For this reason, a higher ABEC rating may not always be the best for all types of skating and conditions of skates.

What are the different ABEC ratings?

The bearings have an ABEC rating, which uses a five-level system, from 1 to 9, to boost the efficiency of supplementary accessories. The levels are summarized below and presented in graphical form in the following resources:

ABEC 1: The bearings of the first rank are the most tolerable. They come at a lower cost but sustain elementary functions.

ABEC 3: This level is more suitable for performance but still relatively basic in precision. It is frequently used on entry-level skateboard designs.

ABEC 5 is a standard skateboard design that provides satisfactory performance in the skateboarding experience, rides smoothly, and has a lower cost.

ABEC 7: This design has enabled higher performance-level grinding and lower resisting rolling friction, making it more suited to speedy skateboarding.

ABEC 9: The highest ranking. The writing has been made to intensify the precision of skateboarding, but its usage may not be entirely realistic in everyday skating scenarios.

Concerning technical specifications, the ABEC rating explains the bore (inner ring) and outer ring diameter and the width of the bearings. For instance, the higher the ABEC rating, the tighter the tolerances. This reduces wobble and vibration, producing smoother rides. Still, these precision levels may not be significant in casual skateboarding, where other elements like the quality of the materials or lubrication are equally important.

What are ABEC 7 and ABEC 9 Bearings?

What does an ABEC 7 say about a bearing?

When considering the bearing of an ABEC 7, I understand it is much more than a low-rated ABEC 1, 3, or 5. The leading sources state that ABEC 7 bearings are meant for those looking to increase their speed while decreasing the rolling resistance. There are warrants regarding tight tolerances, which improve performance and give a smoother ride. Other specifications involve a reduction of wobble and vibration due to tighter tolerances of the bore diameter, outer ring diameter, and bearing width. This need for precision reduces energy loss from motion, which is consistent with the need for speed and smoothness, even though not all types of skateboards might require it.

What does an ABEC 9 bearing bear?

The rating of an ABEC 9 bearing indicates it is the most precise within the ABEC rating system, for its tolerance level is smaller than that of the ABEC 7. This allows for well-defined performance characteristics for users who want high control and speed. Standard features include low friction and a smoother and more efficient roll as the bearing incorporates features to reduce vibration and wobbling. Technical measures include high tightness of the bore & outer ring diameters and thickness, resulting in fast and quiet rides. However, notwithstanding the benefits expected from the ABEC 9 bearings, which will also have high precision levels, these features tend to go beyond the requirements for most standard skateboarding. Still, they are more applied when speed and control issues are crucial.

What are the performance aspects of ABEC 7 and ABEC 9?

When evaluating the performance of the ABEC 7 and ABEC 9 bearings, it is crucial to consider their levels of accuracy and use. Bearings of the ABEC 7 class are characterized by better accuracy and lower rolling resistance compared to lower-grade bearings. They strike a good balance between cost and speed, making them appropriate for recreational and competitive skaters in situations where cost-effective moderate increases in speed are necessary.

The ABEC 9 class bearings have the lowest rolling resistance and the highest accuracy on the ABEC scale, making them the go-to option for manufacturers looking for multi-purpose applications. Such bearings are specifically designed for racing or downhill skating, which require a high level of speed and energy to be maintained. With a typical skateboarding environment, however, this difference may not be as impactful, owing to other variables like the degree of lubrication, materials used, and the environmental conditions, to name a few, enhancing the performance level of the ABEC 9 Bearings.

ABEC ratings are appropriate for measuring bearing tolerance levels, including bore, outer ring, and width. The higher the class, as in ABEC 9, which is an exact class, the tighter tolerances; thus, wobble and vibrations are minimal when the bearing is in operation. This may lead to a better riding experience. However, the practical benefits should be assessed given the kind of skating exercise in progress.

Which Bearing is Better for Skateboarding: ABEC 7 or ABEC 9?

Which type or type of bearings is best suited to the individual skaters?

When deciding what bearings to use for skateboarding, skaters should consider various significant aspects so that satisfaction can be attained:

Skating Style: The skating style heavily influences the choice of bearings. For example, street skaters may want to maximize durability and the ability to withstand abuse, but a racer or downhill skater would probably enjoy maximum speed with minimum rolling resistance.

Material and Lubrication: Bearings are made of various materials, such as steel or ceramic. In general, ceramic bearings are lighter, more corrosion resistant, and offer a smoother ride. With the right lubricant, friction is reduced, and the bearing’s life is extended. To a certain level, different lubricant types provide different lubricant performance characteristics.

Precision and Tolerance: Concerning performance enhancement, all bearings have tolerance levels that are usually expressed in ABEC center ratings, which, as stated, increase the power of rotation with increasing tolerances from low to high as ever, say level 1 to 9 where 1 has low tolerance, and 9 has a high tolerance. It has to be noted that although HP ratings like ABEC 9 bearings provide tighter tolerances and possibly smoother bearings, practically, there is very little difference to the cruiser skate. Wheels, wheel size, and surface texture are just some of the many factors a skater must overcome to get the drive. Precision affects the bore and ring tolerance parameters, which are integral for smooth rotation & stability of the bearing.

Finally, skaters should consider these parameters in terms of their skating situations and tastes, allowing room to trade off the cost against the advantages drawn from higher precision bearings.

How do ABEC 7 and ABEC 9 bearings increase the speed of skating?

The main difference between ABEC 7 and ABEC 9 bearings is their accuracy, which may affect the skate’s speed by reducing the energy lost from overcoming friction. As the skater has a higher rating, the bearings are manufactured with a higher tolerance, and thus, the wheels may run faster and smoother. However, using ABEC 7 and ABEC 9 bearings can only improve speed in particular skating conditions where other elements, such as wheel size, wheel type, surface-wise, or sliding techniques, may be determined.

These ABEC 7 bearings are suitable for most recreational and street skating. They offer a much better balance between accuracy and wear. They are very sturdy and move easily when in contact with external conditions.

This is more useful for the racers because it allows maximum accuracy and the lowest rolling resistance. In such cases, every reduction of the key element of friction is very beneficial; thus, ABEC 9 is all the way.

The sequence of ABEC ratings is determined solely by the tolerance of the bearings. Still, it does not incorporate the quality of the material, the features of lubrication, or the design of the seal, which affect performance. Therefore, higher ABEC ratings such as ABEC 7 and 9 can, in theory, enhance speed; however, real performance improvement should be assessed regarding such factors as these.

Should you be concerned about the performance of your bearings with a higher ABEC rating?

When determining whether a higher ABEC rating is always better for performance, the general understanding of what the ranking of ABEC entails must be underscored. That is, the ABEC scale details the level of the precision of the bearings only. From the sources online, including skateboarding and engineering forums, it appears that high ABEC ratings like those of ABEC 7 or 9 may increase the accuracy of bearings. Still, it cannot be assumed that the increased rated bearings will improve overall performance for all skating purposes.

Several technical parameters define a bearing’s overall effectiveness. Material Quality: The construction of high-quality materials can reduce wear and increase durability, promoting smoother rides at lower ABEC ratings.

Lubrication: Friction and wear must be oil-limited, and bearing life or speed could depend on lube at all ABEC rating levels.

Seal Design: The seals prevent bearings from accessing dirt or moisture, which is essential for performance, especially for outdoor use.

To conclude, although increased ABEC ratings connote accuracy, they are not the only factors on which performance depends. Other factors like material quality, lubrication, and seal design should also be considered. It follows that the optimal solution is not the same for all skaters, and the conditions in which they skate are critical.

What are the Advantages of Using ABEC 9 Bearings?

In what ways do ABEC 9 bearings increase the level of precision?

While examining how ABEC 9 bearings increase the level of precision, I took the time to go through some of the top materials on the internet with the same conclusion, and I was not surprised that they stated that it was due to the internal friction being lower and a higher tolerance due to the more accurate dimensions. Such technical parameters that add to this precision, as narrated on these notable sites, include:

Tightening of Tolerances: The extent to which it is manufactured is very precise, which structurally limits the wobble in the bearing and allows one to ride it smoothly and controlled.

Reduction of Runout: This parameter focuses on the bearing’s axial and radial deflections during operations. Once achieved, it enhances precision and minimizes vibrations.

Quality Materials: Enhanced durability and uniformity in performance are additional factors that contribute to precision through the use of high-quality materials such as high-grade steel or ceramics.

It is worth noting that the design of the ABEC 9 bearings, on the other hand, does not limit the precision level to the ABEC rating. The bearing’s precision is enhanced by the use of high-level tolerances combined with architectural design elements and precision features.

What is the gain involved in the use of high-precision bearings?

In the quest to investigate the gains of using high-precision bearings, I have come across helpful information from the First three websites on google.com that boast enhanced efficiency, increased durability, and overall more robust performance. High-precision bearings can operate at incredible speeds because they have been invented to reduce resistance and friction. It’s also widely reported that they have a long operational life due to their construction from materials such as stainless steel or ceramic, making them more durable than standard materials. The main factors, which are rather technical, supporting these advantages are:

Strict Manufacturing Standards: Just like ABEC 9 bearings, precision bearings are manufactured with specifications that eliminate mechanical play. Therefore, their performance is very stable, as it would not be affected by play.

Special Lubricating Features: Most of these bearings in the field would also contain special features like innovative lubrication to help reduce friction and resultant heat, making them last longer.

Vibration and Noise Levels Reductions: These bearings are also advanced in their designs to limit vibrations and noise readouts when in use, enhancing the user experience.

Thus, it suffices to conclude that when high-precision bearings are utilized in the process, the technology used is reliable, and the return in performance is noticeable.

Are ABEC 9 bearings suitable for any skater?

As far as the above question is concerned, ABEC 9 bearings are meant for all safety; after reading the three articles I found on google.com, this perspective, however, is not universal. As great as ABEC 9 bearings are for high-speed skating, not every skater should use them. The technical parameters that could provide sufficient justification for their use include:

Speed: For those into racing or downhill skaters where speed is everything, ABEC 9 bearings would suit you as they spin with minimal effort and are designed to ensure minimal friction and high tolerance.

Surface conditions: The ideal surface for ABEC‘s usage is marketed as smooth and well maintained. Uneven or unkept surfaces might not attain the bearing’s desired usage potential.

Skill levels: The increased altitude of the bearing’s responsiveness will benefit experienced and advanced skateboarders, while the casual or beginner skater won’t experience the same advantages.

In conclusion, while specific applications may require the advanced features of ABEC 9 bearings, they may not benefit skaters whose requirements do not match the bearing’s high-precision nature.

Are ABEC 7 and ABEC 9 Bearings Suitable for Inline Skates?

What are the distinctions between skate bearings and inline skate bearings?

There is a need to understand how skate bearings may differ from inline skate bearings, and for that, I referred to the three primary sources on google.com. Though bearings for skates and inline skates tend to perform the rotational movement for the wheels in the same way, they differ in many aspects that affect their operations.

Bearing Size: Skateboards tend to exert higher sideways forces on their bearings because of their tricks, so larger bearings are employed. However, inline skate bearings are smaller as a result of their internal placement within a set of inline wheels.

Durability and Strength: Skateboard bearings are heavier because of the heavy axial Isk8e lateral loads commonly applied during tricks. However, inline skate bearings are designed with restraint smoothness and speed, as more motion is forward, thanks to the inline skates.

Lubrication and Friction: Bearings on skateboards rely on effective friction control to achieve faster speeds and a greater level of control over the skater during stunts. On the other hand, INLINE bearings are designed to contain lubricants that help maintain ease of use during extended sessions on inline skates.

When these parameters are considered, selecting the most appropriate bearing would be a simple task. It would depend on the type of usage and skating style being practiced, and the optimal performance of the bearing would depend on the tasks assigned to it.

What purpose does an ABEC 7 or ABEC 9 bearing serve when fitted to inline skates?

The ABEC 7 or ABEC 9 bearings can be fitted onto inline skates. Nevertheless, it is essential to consider some of the technical parameters associated with these bearings before making a choice. The three parameters published on three of the websites were the following:

Warranty of Accuracy and Distance: It is well established that both ABEC 7 and ABEC 9 bearings have an excellent precision level. This allows for much smoother and possibly faster rides, which are ideal for skaters who are into speed and long-distance skating.

Ability to Withstand load: It is widely accepted that the higher the rating of an ABEC bearing, the more precise it is, but that does not mean that the strength required for some aggressive or rough skating styles is automatically there. So, the skating environment must be considered against the durability features of the bearing.

Possibility of requiring lubrication: This type of bearing usually works at higher speeds that are efficient only when proper lubrication is done. Regular maintenance is very important so as to prevent friction related problems and get the most out of the bearing.

Once I understand all these factors, I will be better able to decide whether ABEC 7 or ABEC 9 bearings would meet my inline skating bearing requirements in terms of speed, precision, and strength.

What is the ideal ABEC rating for inline skating?

The ideal ABEC rating for inline skating varies from one person to another, taking into account the personal preference of the individual skater and the type of skating most commonly practiced. The three top-rated websites on Google do not address this issue specifically. However, certain practices may provide some pointers. Most skaters prefer using ABEC 5 for most purposes as it allows them to attain pretty good speed and use their skates for an extended period without requiring any extra maintenance, which is demanded by higher-rated skates. Nevertheless, a rating ranging from 7 to 9 ABEC may be necessary if I am mainly concerned with speed and accuracy. Here’s a short explanation of why that’s the case using the technical parameters as a guideline:

Precision and Speed: Higher ABEC ratings like 7 or 9 increase the bearings’ precision, which in turn improves the overall ride quality and allows much faster speeds to be attained, making them ideal for racing or long-distance skating.

Strength: On the other hand, when skating aggressively or on rougher surfaces, using lower ABEC bearings such as 5 can increase overall strength as they are built to withstand more wear and tear while maintaining efficiency.

Maintenance Requirement: The maintenance schedule is tighter because re-lubrication and essential servicing are necessary more often than they would normally be for a given performance level. I need to consider this in relation to the amount of time I am ready to devote to servicing the equipment.

These parameters, in conjunction with my special skating needs, should allow me to choose a suitable level of the ABEC rating for my inline skates with more confidence.

Frequently Asked Questions (FAQs)

Q: How do ABEC 9 and ABEC 7 skateboard bearings differ?

A: The main distinction between the two bearings lies in their tolerances. ABEC 9 bearings are tighter in tolerances than ABEC 7 bearings and hence allow more precision, which can lead to tighter rides at higher RPMs. This means that bearings rated ABEC 9 can perform better, especially at high speeds.

Q: What does the ABEC stand for, and how does it relate to the skateboard bearings?

A: The ABEC is an acronym that denotes a rating system appointed by the Annular Bearing Engineering Committee to classify the bearing ball bearings and skateboard bearings. ABEC has nine ratings of bearings; the lowest are ABEC 1 and ABEC 9, which are the highest and more precise tolerance levels than the other.

Q: What is the definition of a high-quality skateboard bearing?

A: A good skateboard bearing would include high-quality construction such as ceramic or stainless steel components, low friction, sufficient lubrication, and the appropriate ABEC rating for the rider. Additionally, suitable bearings, such as sealed or shielded types, should be well-designed to avoid the intrusion of dirt and debris.

Q: What are the details about ABEC 1 bearings compared to ABEC 9?

A: Of course, ABEC 1 bearings are the least precise and have the lowest tolerance. This lower precision, however, bears the risk of increasing friction and still less smoothness during faster speeds. By contrast, the tighter tolerances of the ABEC 9 bearings enable greater RPMs and smoother rides.

Q: What is the meaning of the numeral 608 in skateboard bearings?

A: It refers to the size of the bearing, which is a widespread standard in skateboards. It denotes the diameter and thickness of the bearing, including its inner and outer diameter. Most skateboard bearings typically revolve around the 608 type, which are ABEC-rated bearings.

Q: What new characteristics do ceramic bearings bring into skateboards?

A: Since ceramic bearings are made from ceramic materials, they tend to have lower friction and higher life than steel bearings. Typically, they are lighter and are incapable of absorbing heat or rust. Such properties make it easier for ceramic bearings to find skateboard applications as they ensure high performance.

Q: How should I choose the correct set between ABEC 5 and ABEC 7?

A: When determining whether to use ABEC 5 or ABEC 7 bearings, consider your skating type, skating frequency, and how often you skate outdoors. Most skaters could find an ABEC 7 bearing, which may seem to give you a performance of durable balance. In contrast, good performance can be found in skaters who tend to use ABEC 5 bearings occasionally for common skating.

Q: When should I use the lubricant for my skateboard bearings?

A: This can take quite long depending on how often they are used. If you plan to ride a skateboard in water, brush it a few times to ensure the bearings are well protected. It’s suggested to apply lubricant in every few rides or after riding the skateboard on sand or wet surface. Metal parts may not last without lubricating them regularly.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8