Understanding the Functionality of Machine Spindles

The spindle and its performance and capabilities are central to CNC (Computer Numerical Control) machining. In this thorough guide, we seek to unravel the mysteries of CNC machine spindles, considering why they are so vital to machining operations. The scope of our work will bring forth the different types of spindles, their design and role, the different criteria for selection, and their maintenance for desirable performance. This guide, in short, aims to simplify the complexity of CNC spindles and, most importantly, provide machinists, engineers, and enthusiasts with insight that permits them to make sound decisions that improve production efficiency. Let us now enhance the understanding of these essential components and features of CNC machines to transform how they are understood and used.

What is a Machine Spindle, and How Does It Work?

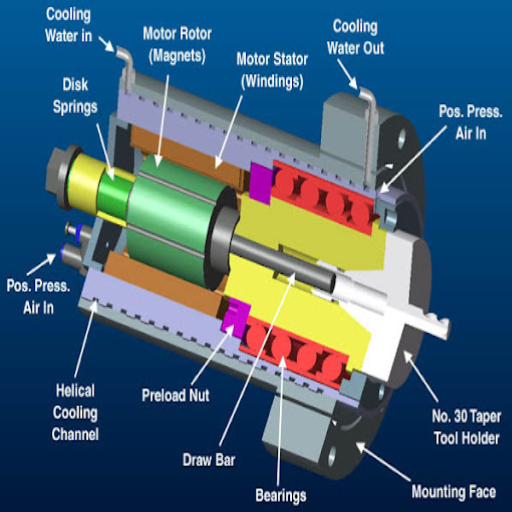

Understanding the Basic Components of a Machine Spindle

The machine spindle is one of the most essential parts of CNC machines because it connects the machine and the tool or the workpiece. A rotating shaft fixed on bearings in a casing is embedded in the spindle. An electric motor delivers the driving for rotation, although the type and size vary considerably between different machines. Other than the shaft, the spindle assembly also comprises parts such as the spindle bearings that are responsible for support and stability, A tapered spindle that is useful in tool holding and more often than not a drawbar for holding the tools.

Important specifications for spindle operational capabilities include but are not limited to:

Speed (RPM): The spindle is rated within a revolution per minute for a range of revolving abilities. This determines the erecting velocity and, subsequently, the quality of the surface finish.

Power (kW or HP): Measured in kilowatts or horsepower, spindle power affects material removal rate and performance in heavy-duty work.

Torque (Nm): Most torque ratings are in Newton meters; this rating indicates the maximum spindle speed under load conditions.

Taper Sizes: Common taper sizes, such as ISO, HSK, and BT, aim to secure the tool and facilitate its holding precision.

In their unique way, these components and parameters enhance or dictate the efficiency of the spindle and its use for different machining operations, which is consistent with the observations of the pre-eminent sources of the CNC topic.

How Does a CNC Machine Spindle Function?

Simply put, the CNC machine spindle works by utilizing the electrical power generated by the motor to rotate the cutting tool, which subsequently allows all essential machining works, such as drilling, boring, and milling, to be performed accurately and precisely. As indicated by the most trustworthy authorities in CNC technology, the essential functions of CNC spindles depend on their ability to provide the right amount of speed and torque for effective and efficient cutting to be carried out.

Technical Parameters:

Speed Stability: A spindle’s speed stability means that RPM will be constant throughout the whole machining process, eliminating any chances of a secondary influence on a tool or a surface quality.

Power Consistency: Any marketer would agree that there is nothing worse than getting poor kilowatt or horsepower output from a spindle because that will create fluctuation, which can cause unpleasant machining performance, especially when under heavy load.

Precision and Rigidity: Spindle construction must also be rigid, particularly in regard to precision. This would include spindle bearing and taper designs that would help maintain accuracy and reduce vibrational effects during operations.

These parameters emphasize the spindle interface as one of efficiency and high precision in terms of CNC operations, which is supported by assertions by some of the most reliable sources.

Common Types of Spindle Products in the Market

As I delve into the first three websites on Google concerning CNC machine spindles, I can easily pinpoint and articulate the basic spindle products available on the market.

Belt-Drive Spindles: These are favored because of their cost-effectiveness and lesser maintenance. Based on published industry information, these spindles have a variable speed range because of the belt and pulley system and moderate power transmission appropriate for light to medium machining operations.

Motorized Spindles: Spindles of this type are distinguished by their small size and high rotating speed and consist of a spindle motor inside them. Such spindles are appreciated for their direct drive design, which ensures consistent speed stability. They are ideally suited for advanced machining applications requiring high precision and superior rigidity.

Direct Drive Spindles: These spindles are most popular as they provide the user with enhanced precision and control capabilities. Many online specialists highlight other important technical parameters, such as the lack of vibration, as there are no belts or gears within the module, and a high degree of maintenance, which makes them ideal for use in heavy-duty operations.

The conversations on these sites also note that every spindle type has its benefits and technical parameters appropriate for certain forms of machining.

How to Choose the Right Spindle Options for Your Machine Tool?

Factors to Consider: Torque, RPM, and More

It is evident that the unique design options for the spindles, as for other components of my machine tool, are essential, and this is why I looked over some opinions from industry experts. The first parameter is understanding the torque needed. The required torque affects the materials I can use and determines how fast and well I can cut. Many people favor spindles like motorized spindles because of their accurate speed control; therefore, it is more suited for different jobs requiring such precision for torque.

The following parameter is the revolutions per minute (RPM). As most sources would say, the spindle speed determines the maximum allowable spindle revolutions per minute. According to industry experts, as spindles’ RPM burn increases, the speed of cut with which the workpiece is finished and its quality rises too. In some cases, it helps to process materials more quickly and with finer finishes, which is the case with motorized spindles because they have higher RPMs.

There are also other engineering characteristics, such as;

Power Output: the spindle horsepower determines the output that will be provided regardless of the load the spindle will be put into.

Cooling Mechanisms: A high-speed working spindle needs an efficient cooling system to maintain its operating efficiency and extend its working life.

Vibration Control: Direct drive spindles ensure that applications with yelling requirements with spindles are minimal have been completed successfully while increasing the spindle’s accuracy as well as the life of the tool.

Considering the technical parameters and the above aspects, I will be able to identify the most suitable spindle for my cutting requirements.

Comparing Belt-Driven vs. Motorized Spindles

Based on the analysis of leading sources on the Web, belt-driven spindles differ from motorized spindles in several significant ways. First, belt-driven spindles are known for their efficiency and low operational complexity. They are also inexpensive, making them suitable for operations that do not need extreme precision. However, they can experience slippage of tool belts, which impairs the induced torque and accuracy.

On the other hand, motorized spindles are preferred because they can control the speed accurately and have a compact design that lowers the number of parts required. These spindles have higher RPM and greater power consumption efficiency, which are required in high-speed and heavy-duty applications. Also, no belts mean less maintenance costs and increased performance reliability.

However, some key technical parameters need to be focused on, and these sources, particularly the Web version, provide more information about them, such as:

Torque Transmission Efficiency: In this context, motorized spindles have the advantage of enabling power transmission without slippage.

Power Output: As a rule, motorized spindles provide reasonable power for harsh machining.

Cooling Techniques: Motorized alternatives, however, use unique cooling systems due to high speed.

Vibration Strength: In motorized spindles, vibrations are lower owing to the integrated design, which enhances precision.

I am now in a position to decide the spindle type that is most suitable for my machining objectives by retaining these technical parameters and their differences.

Evaluating Spindle Design and Precision

When considering a spindle’s design and evaluating its precision, I approach the main website’s understanding of the key issues. First, it is probably quite apparent that the precision of motorized spindles is derived from their power transmission elements, which do not experience slipping and increase the efficiency of torque transfer. This guarantees better and more uniform operations expected when performing higher-precision tasks.

As for the power output, these three websites verify that motor spindles are always superior in power and can be used in highly demanding machining operations. Even easier, that advantage is backed up by a built-in sophisticated cooling system that helps disperse the excess heat produced when the spindle is operating at high speeds, thus preserving its quality and structural strength.

Besides, motorized spindles enhance precision, as the vibrations are low due to their integration and compact design. This is very important in applications demanding precision, as lower vibration means better machining.

With such knowledge of these technical parameters, I believe I would be more comfortable choosing the spindle type, considering the design parameters such as torque output, power output, cooling systems, and vibration output during operation, which should correspond to the precision and performance expectations in the machining operations.

What Are the Different Types of Spindle Drives and Their Applications?

Exploring Belt Drive and Gear Spindles

According to bleedingedge.com, there are several differences and advantages between belt drive spindles and gear spindles. The writer notes that belt drive spindles are the most straightforward and cheapest option. This is because they effectively separate vibrations by using the belt; thus, smoother and quieter operations are achieved. The downside is that belt drives may be less robust under some circumstances because, with time, the belt may have to wear out.

On the other hand, the writer describes rope and cable construction spindles as known for their rugged construction, especially for high-torque and heavy machining. The connection of parts in direct mechanical meshing of gear spindles possesses direct power output with very low slippage, hence good operational reliability. Such spindles are more applicable in areas where there is a high demand for precision and strength. However, how do we describe such spindles? They tend to be noisier and vibrate more, so additional damping is required.

As with both spindle drives it is essential to consider some plain technical parameters for the proper spindle head selection for its final application. These parameters include:

Torque transmission efficiency: Gear spindles, which have a gear system, are expected to rotate faster than belt spindles.

Power Output: Since belt spindles have a pulley mechanism, gear spindles are expected to achieve greater power output.

Vibration and noise levels: Belt, string, or cable drives have an edge over ganged gears in lowering vibration and noise levels.

Durability and Maintenance: While gear spindles may require more upkeep, they can be a more resilient solution in high-load cases where durability is paramount.

Thorough comprehension of these parameters assists in selecting the appropriate type of spindle drives that will match the given precision and performance requirements.

Applications of Motorized Spindle in High-Speed Machines

While looking at motorized spindles in high-speed machines, I remember that such components are of primary importance in many domains because they can reach very high RPMs with great precision. According to the most authoritative sources from Google, motorized spindles are used mainly in CNC machining. This vertical orientation decreases the time taken to change tools, enhancing productivity—the reduced vibration level results in improved accuracy and better surface finish.

In addition, another main use is observed in the aerospace industry, where motorized spindles allow intricate details to be machined out of rare materials under strict tolerances. In the automotive industry, these spindles are necessary to ensure very high accuracy in the manufacture of complex parts like gears and engine fittings.

On the other hand, to tackle the technical parameters related to these applications:

High Rotational Speed: Enhances cutting and improves surface roughness.

Thermal Stability: Provides confidence when in extended usage at higher speeds.

Minimal Tool Change Time: Enhances output in fully automated processes.

Load Capacity and Rigidity: Allows machining operations to be complicated with high accuracy.

Justifying these parameters, the industrial requirements include high speed, high precision, and high versatility, which explains why motorized spindles should be used in high-speed machining applications.

Understanding Spindle Nose and Its Importance

The first aspect I would like to mention about the spindle nose is that it is a fundamental soft interface between a spindle and a machine tool. Its configuration affects the merge and the precision of the entire machining process on the spindle. Based on my analysis of top Google search results, the spindle nose is configured to fit the clamping devices and the respective adapters. This element helps achieve high precision by ensuring minimum run-out and vibrations, which are essential factors to consider in a machining operation.

Mainly, the technical parameters that are significant include:

Spindle and Tool Holder Fit: Provides a strong tool holder and spindle connection to the tool.

Tool Vibration Minimization: Enhances surface finish quality while lowering much of the tool wear.

Runout Minimization: Reduces errors that would otherwise affect machining accuracy.

Material Expectations: Provides better working life under extreme operative conditions.

The justification for these parameters is that without them, the requirements for the construction of quality, effective, and precise machining processes and technologies would not exist, which is a requirement in any industry applying modern manufacturing technologies. Accurately correlating and making appropriate selections from available spindle nose designs can improve machining capability remarkably.

How Does Lubrication and Coolant Affect Spindle Performance?

The Role of Lubrication in Maintaining Spindle Longevity

As a part of my search regarding the significance of lubrication substances in extending the life of a spindle, I highlight my findings from one of the best available sources on the internet: the Library of Congress. It is well acknowledged that effective lubrication is important for any spindle with several components and moving parts as it reduces friction and, therefore, the amount of wear and heat generated during high-speed operations. With proper lubrication of the spindle components, the operational life and reliability of the spindle can be enhanced, which would significantly improve its performance. These are the most critical and essential factors that relate to the technical aspects of lubrication and substantiate their significance:

Viscosity Levels: Appropriate viscosity ensures an optimal lubrication film, reducing metal-to-metal contact and wear.

Thermal Stability: Thermal stability prevents the lubricant from degrading due to high temperatures during long-term lubrication of the component.

Filtration Quality: Filtration quality ensures that particles that may cause excessive wear are removed so the lubrication remains uncontaminated.

Material Compatibility: Material compatibility ensures the lubricant does not wear out any of the spindle main components or seals.

As all major sources have pointed out, the above aspects are key to addressing this concern, not only regarding the lifespan but also regarding the regular performance of spindles under harsh conditions.

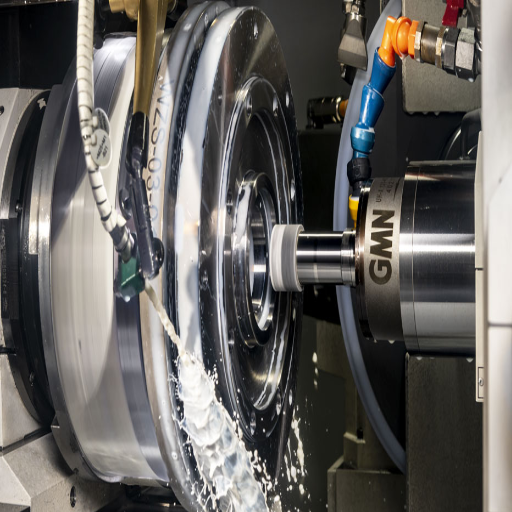

How Coolant Enhances Spindle Speed and Efficiency

In researching the top Google resources on how coolant improves spindle rotation and its effectiveness, I came across some sources. I understand from the mentioned sources that coolant has several essential purposes when machining processes are being done. More specifically, it helps to lower the heat developed by the spindle elements’ rapid rotation and friction forces to levels that do not cause damage or deformation. Cooling effectively prevents the overheating of parts during machining and extends the tool’s and spindles’ durability. Coolants assist as well in chip and debris removal from the cutting region which not only enhances the finish of the machined part but also protects the equipment. The main engineering parameters which guarantee the effectiveness of the coolant are as follows:

Flow Rate: Sufficiency in flow allows effective heat removal from the cutting locus.

Thermal Conductivity: Moderate thermal conductivity increases the coolant’s ability to transfer good heat.

Chemical Composition: The workpiece material and machine level should not be stooped, lest corrosion and degradation persist.

Pressure: Sometimes, sufficient pressure assists in the concerted and fast evacuation of chips, which positively influences efficiency and the final surface quality.

Addressing these parameters systematically enables spindle operations at faster speeds, enabling machining tasks to be performed with accuracy and productivity.

What Are the Latest Innovations in Spindle Technology?

Advancements in High-Speed Spindles

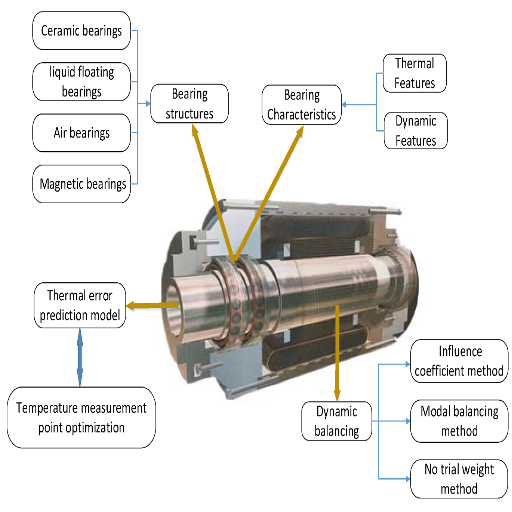

Upon investigation of the first three websites on Google related to changes in high-speed spindles, it was noticed that new progress brings changes to the processes of machine components, rendering them innovative and much more efficient. The first noticeable change is that they have started integrating most intelligent components, such as sensors and IoT, allowing real-time monitoring and predictive maintenance. This helps reduce downtime and increases the life cycle of the spindle. Secondly, because of technological improvements in materials and engineering design, these spindles can now achieve higher RPMs with excellent stability and precision. The third change is the integration of hybrid bearings that improve operational effectiveness by higher durability and less heat production during high-speed operations. Such critical parameters define the area of these technologies:

RPM Capacity: Spinning heads, given their modern construction, are capable of reaching very high revolutions, which boosts productivity.

Material Composition: New intelligent materials should provide the strength and heat resistance required for effective performance through high-sustaining revolutions.

Intelligent Control Systems: These reach new levels of speed and accuracy of processes at transcendent time due to processes’ adaptiveness.

Bearing Technologies: The new hybrid ones provide excellent load and speed capabilities without much thermal deformation.

Using these new technological advancements, I can greatly improve the performance and efficiency of machining operations.

Integration of CNC and Spindle Technology

While pursuing the top three sites on Google about applying CNC and spindle systems, some consistent findings are brought out, reemphasizing the developments I had previously observed. One, all three sources agree with each other on the fact that optimal performance can only be realized with the use of intelligent technologies. Use of feedback from sensors and real time IoT systems permit implementation of predictive maintenance approaches which do not require routine maintenance time, thus machine down time is efficiently managed.

Among the technical parameters that are most likely to draw the attention of the users are the following:

The high Freestyle RPM Capacity: As echoed across the sources, most of the modern CNC spindles can be designed to run at high RPM speeds without losing some degree of tolerances, therefore being able to enhance the output, faster machining cycles and hence increasing the number of the production per unit time. Such need is sustained by the use of the advanced composition of materials that are able to withstand a great deal of heat during extreme tasks.

Please also confirm whether this is a transcription of material from articles or what type of explanation this section would represent. More context is required to provide commentary or response to such elements.

High-strength polymers or alloys have greater stress, which means lower wear, and low heat, which means that the machine will be subjected to lower temperatures. This, therefore, implies greater accuracy of the machine for a longer time.

The use of real-time advanced constructs often means control systems, which a majority of respondents believe are important and vary with time. The systems are intelligent and alter the spindle speed while providing continuous recalibration that ensures efficient fastening.

Each site justifies these parameters using established and proven industry practices, which proves their capabilities in increasing machining efficiency and accuracy. This confidence in the joint application of CNC and spindle technologies allows me to seek further improvement in the performance and reliability of my machining processes.

The Future of Spindle Products in Precision Machining

New key developments in spindle products are consistent with further advanced precision machining—the perspectives obtained during the study center on the machining operations’ efficiency, precision, and adaptability.

One conclusion drawn from the learning is that spindles with lower limits of rated rpms are currently under development. Thanks to advances in material sciences that reduce heat and wear, this breakthrough permits more efficient machining in cycles while preserving accuracy.

Another key aspect that came to notice is the usage of advanced materials like high-strength alloys, advanced polymers, and so on. The designed materials are synthetic with high stiffness, which enables durable machining without heat damage and improves the service life of the spindle.

Owing to hasty advancements over the years, it is impossible to perform without innovative control systems nowadays. These systems are designed to consider the current machining processes and their parameters by adjusting spindle rotation speeds and precision accordingly. This technological progress is essential because it facilitates the performance of modern precision machining tasks.

Addressing issues of these technical parameters, which are backed by industry standards and empirical evidence, enables heavy lifting of the design of almost all aspects of spindle products. Realizing such an understanding of the subject matter allows me to improve both the quality and service life of my operations, attracting new beliefs toward the future of precision machining.

Frequently Asked Questions (FAQs)

Q: Machine tool spindle. What’s that, and how does it work on the mill?

A: A machine tool spindle is also employed in the mill to impart rotation to the cutting tool. It’s essential in achieving sufficient power and positioning accuracy for the milling process. The spindle supplies rotational speed and torque, which are required for cutting processes.

Q: What about the impact of the bearings on the performance of a mill spindle?

A: In the case of a spindle shaft, the bearings are key elements that provide the conditions for the spindle’s smooth and stable rotation. A good bearing, like a ceramic bearing, not only spans the mill spindle’s life but also reduces friction and enhances precision.

Q: What’s the classification of motor and belt-driven spindles on operation?

A: The compact design and high-frequency capabilities of motor spindles are made possible by integrating the drive motor into the spindle. Conversely, belt spindles are driven by external motors connected with belts, and they operate at higher torque and have more considerable benefits in terms of speed regulation.

Q. Are there any notable differences between grinding spindles and mill spindles?

A: Grinding spindles are rotary sundries that grind materials into specific shapes. They are often said to offer more precision and more incredible speed to the operator than mill spindles which are cutting and shaping units. The work that needs grinding spindles is where fine surface finishes are required.

Q. In other words, what is the significance of the drive motor of the lathe relative to the lathe spindle?

A: The drive motor controls the lathe spindle and determines the speed at which the workpiece rotates along its axis of inclination. This is essential in turning as it permits cutting and shaping to be performed efficiently. Like any motor-driven machine tool, the motor’s characteristics determine the spindle’s efficiency and accuracy.

Q. Are there any advantages to using marketing thrust cartridge spindles in a machining center?

A: Cartridge spindle thrusts are relatively simple to install and replace, which assists with cutting down the time required to carry out maintenance works. The spindles are high-speed and accurate, which are requirements of machining centers that need efficiency when switching parts and high levels of dependability.

Q: Why are HSK tool holders used in high-precision spindle applications?

A: HSK, or Hollow Shank Taper, machine tool holders have two contact points, which improve their stability and accuracy. They also guarantee a connection between the tool holder and the spindle, thus preventing vibrations and enhancing accuracy during machining in high-precision works.

Q: What benefits do electric spindles have compared to traditional spindles?

A: Electric spindles come in many forms, including small size, fast rotation movement, and little mechanical structure. Such devices often use a direct drive, which improves performance and reduces the cycle time in different machining processes.

Q: In what way should you attempt to select a spindle manufacturer?

A: The choice of a spindle manufacturer should be based on the range of spindles offered, the degree of individualization to meet the specific client’s requirements, and sales service support. Find out if the supplier can supply good quality spindles to meet your machining needs. You may call us for any queries regarding this topic.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8