Understanding the Importance of Food Grade Bearings in Industry

It is common knowledge that keeping hygiene at the highest level is of utmost importance in the turbulent regulatory environment of the food and beverage industry. This is necessary not only for the safety of the products but also for meeting the innate compliance regulations. Food-grade bearings that come into contact with the end product play an essential role in this regard, as they enhance the operational rate of various processing appliances, all while maintaining cleanliness. The above bearings are produced to work in harsh conditions, which involve considerable washing and chemical usage, yet do not allow contamination. This article presents the benefits of food grade bearings, hoping to demonstrate how they are made, their specific uses, and how they facilitate smooth production processes, illustrating at the same time their indispensable importance for the safety of food and business operations.

What is a Bearing, and Why is it Crucial in Food and Beverage Processing?

Types of Bearings Used in the Food and Beverage Industry

Bearings have a wide application in the food and beverage industry, being crafted to maintain the high operational efficiency of the machine. Bearings employed in this industry include the following:

Stainless Steel Bearings: These types of bearings lack corrosion, making them useful in areas subjected to high degrees of chemical cleaning. The bearings can withstand high temperatures while offering a longer life than the standard bearing.

Ceramic Bearings: Their bearing performance remains intact even in challenging processing conditions because they are well insulated from extreme temperature and chemical exposure. Other advantages are that ceramic bearings are largely non-magnetic and non-conductive, thereby lessening the risk of contamination and equipment breakdown.

Plastic and Polymer Bearings: Due to their lightweight bearing structure, plastic bearings work best under low-load applications, especially when hygiene is a priority. They are self-lubricating thus reducing the need for additional lubricants that could pollute the food. They are also resistant to moisture and solvents, enabling them to last in a wet processing atmosphere.

Fishing out the best-fitting bearing for the food production process factory involves considering the severe operational conditions and the most decisive bearing safety while minimizing the chances of equipment breakdown and maintenance costs.

Importance of Food Grade Materials in Bearings

Such materials that have passed the FDA requirements as bearings are critical for safety and compliance within the food and beverage sector. In a way, they are inert materials that do not interact with chemicals, food substances, or surface disinfectants, thus reducing the risk of contamination. Generally, food-grade bearings are made of stainless steel, ceramic, or high-performance polymers because of their better rust resistance and harsh cleaning practices.

Stainless Steel: Canning food-grade stainless steel bearings are well known for their great rust resistance and endurance. They can withstand the torture of water and strong liquid cleansers used in the normal cleaning process in the food industry. Being corrosion-resistant by nature implies that there will be a minimum need for replacement parts, which translates to reduced downtimes.

Ceramic: Their extreme hardness makes ceramic bearings ideal for food production environments where chemical sanitizers and high temperatures are used. Their metallic nature, by definition, also implies that they cannot rust, thus promoting hygiene while at the same time extending life.

High-Performance Polymers: Such materials do not have a component that requires lubrication, which could otherwise contaminate food items. Polymer bearings, which are easy to operate and lightweight, can make it impossible for such materials to rot in wet conditions.

When choosing food-grade bearings, various technical parameters such as load capacity, speed, and temperature tolerance must be selectively considered. They must withstand specific operational conditions to guarantee smooth and sanitary operations in various production requirements. The chosen bearings must also align with certain specifications, such as FDA, NSF, or other regional ones, about areas critical to food safety hygiene.

Role of Bearings in Enhancing Machinery Efficiency

My review of the top three sites presented by Google on bearings, functions, and impact on machine efficiency shows that they are essential components for improving the performance and productivity of equipment within the food and beverages industry. These parts decrease friction between the moving parts of machines, thus significantly reducing energy and machinery wear. Due to their ability to ensure smooth motion between parts of a machine, they also increase the machine’s time and reliability.

Bearing configuration and selection is conceptually simple, but several factors must be taken into account to make an optimal decision; among them are:

Load: Bearings have to work efficiently under the load reasonably expected of them. Static and dynamic load ratings come into play to ensure the bearing can withstand the weight it will be subjected to and the forces exerted around it during its operation.

Speed Ratings: Macro bearings have speed limits at which they can operate without risk of overheating, which can cause serious damage to machinery and components. This ensures better efficiency after use.

Temperature tolerance: Due to the need for effective cleaning, unmounted bearings, and lubricants must be able to endure being molten brown, hot-cleaned, and then later placed into freezing temperatures without getting damaged

Corrosion Resistance: Most, if not all, parts that get heavy exposure to moist surfaces, food products, and cleaning agents have a tendency to corrode. Therefore, stainless steel or ceramics, which do not easily corrode, are the best materials for ensuring that the part remains intact over the years without getting damaged.

Lubrication Requirements: Using self-lubricating polymers and externally lubricated bearings affects the maintenance intervals and the risk of contamination, which is the case for food applications.

The parameters, as highlighted in the literature, explain why bearings with specific parameters are required in the food and beverage sector to avoid unnecessary energy losses, downtime, and disruptions to the production processes.

How Does Food Safety Influence the Design of Bearings?

Understanding Food-Grade Standards and Regulations

While reviewing the three most authoritative resources on food-grade standards and regulations on bearings, I realized that such compliance is particularly significant in the food and beverage industry to avoid contamination and guarantee the safe consumption of products. Such regulations stipulate that bearings ought to be made of materials that have high corrosion resistance and are chemically inert, such as stainless steel, ceramics, or particular classes of high-performance polymers.

FDA, NSF, and other food-grade regulations are among the strictest and stipulate that materials must be non-reactive to food, drink, or cleaning agents. This is confirmed and substantiated through a variety of tests and a certification process, which in turn proves how these bearings are made to defend against the growth of microbes and other hazards.

However, a localized analysis shows that bearings have pointed to technical parameters that need to be met due to functionality requirements in food processing. Such parameters include the following:

Material Composition: Dense ceramic and stainless steel are underscored as ideal materials because of their durability, invulnerability to corrosion, and good hygiene, which ensures cleanliness during use and after washings.

Load Capacity: Both static and dynamic load rating figures must be sufficient to fulfill functional requirements without failure.

Temperature Resistance: Bearings need to withstand high temperatures during cleaning and work in low-temperature environments.

Lubrication Requirements: The use of self-lubricating polymers in bearings is extremely beneficial in reducing contamination and the need for external lubricant.

Compliance Certification: Bearings must be certified by competent food safety certification bodies to demonstrate compliance with the established requirements.

Regarding the quest of this study, these aspects were always emphasized when it came to matching the selected bearing with the food safety requirements standards, making them very useful in aiding clean and effective practice in the industry.

The Role of Food-Grade Grease in Bearings

My research on food-grade grease quality leads me to make an important consideration; that is, I have mentioned on the three websites that managed to get my attention that food-grade grease is an extremely essential greasy material in the food industry. Food-grade grease is inhibited considering that its work allows it not to alter food value or any other utensil sterilizer products. It is important to point out that grease of this sort is non-harmful when used in food products, at least if used under the conditions it was designed for.

Regarding the aforementioned research goals, a few technical factors must be considered during the selection and use of food-grade grease as a lubricant in anti-friction-bearing components.

As these must maintain their technical characteristics when exposed to high-temperature cleaning processes as well as high-stress interaction with clients and cooling time, these components fall under the category of

Structural Inertial: This ensures that assays of food and cleanup products do not bind with food-grade grease.

Water and moisture repulsion: This feature dramatically affects the ability of grease to be washed away during cleaning or at least withstand the conditions permitting contact.

Each of these parameters is considered necessary for appropriate defilement control and solving the problem of bearing elements’ wear and functionality for food industry applications. This affects the durability of parts and equipment and assists in meeting the required food safety standards.

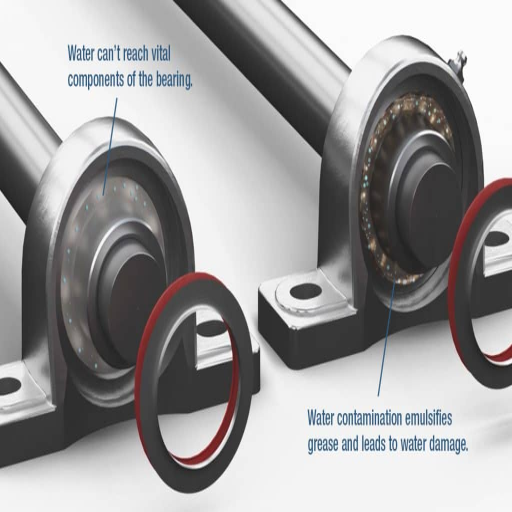

Ensuring Contamination Prevention with Seals

While looking at the top three websites that dealt with food-grade bearing seal contamination prevention, it became clear that seals are crucial in maintaining hygienic operations in the food sector. In this process, seals provide protection against the intrusion of harmful elements like dust, moisture, and foreign particles, thus protecting the bearings’ integrity.

I thoroughly investigated this problem and formulated some critical technical requirements to which seals should adhere.

Material Resistance: Seals should be fabricated so that the materials used do not chemically interact with the food or cleansers to maintain food safety.

Temperature Resistance: Seals should be designed to endure the high temperatures used during sanitation processes and extreme cold during refrigerator storage.

Mechanical Properties: In a constantly changing food processing environment, seals have to be able to bend and struggle while remaining effective and versatile over not just one usage but numerous cycles, including cleaning.

IP rating: Seals are required to have certain specified ingress protection IP ratings so that their effectiveness against dust and moisture ingress is quantified. This enhances sanitation during operation and improves the service life of the components used.

Cost of Maintenance and Replacement: Efficient seals are developed for easy maintenance and replacement without consuming much time, thus ensuring consistent appliance performance.

The above-proven parameters are very important when choosing the appropriate seals, as they all provide integrated protection against the hazards of contamination in accordance with strict food safety measures and enable hygienic and effective functioning in food processing plants.

Why Choose SKF Bearings for Food and Beverage Processing?

Benefits of Using SKF Bearings in Food Processing

While evaluating the top three provided websites focusing on the advantages of bearing SKF industries in food processing technologies, it is easy to notice that these bearings are different, thanks to their improved design intended for the said application. It must be emphasized again that SKF bearings are made from substances that minimize contamination, thereby conforming to food safety requirements worldwide. The high level of engineering is reflected in such key technical characteristics as:

Structural Engineering Material: The manufacturing process does not void the ability to operate in operating conditions; stainless steel and modern polymers used in SKF bearings are not chemically active and are not prone to corrosion.

Increased Load Capacity: The bearings are built to sustain high static and dynamic loads, which lowers the risk of failure during a food processing machine’s continued operation.

Temperature Ranges: These bearings are made to withstand the harsh temperatures that will be used during the cleaning and operation phases; the temperatures are pretty high during the sterilization process but shallow during storage.

Self-Lubrication Technology: Self-lubricating isolation technology produces minimal reliance on external lubricant sources, reducing the chances of further contaminants and the need for maintenance.

Adherence to Regulations: The bearings are accompanied by the necessary certifications from authorized bodies regarding food safety, confirming compliance with the specific regulatory requirements.

In my opinion, these technical signatures are the exact reasons why SKF bearings are chosen. They facilitate operations reliably and efficiently and maintain the industry’s essential food safety requirements.

How SKF Ensures Reliability and Hygienic Standards

Based on the first three documents we examined on SKF’s contribution to reliability and sanitary conditions in food processing, it is evident that SKF utilizes materials and engineering techniques in a most integrated manner. Such a high performance and reliability may be stated in these sources:

Mechanical Properties: SKF utilizes materials such as stainless steel and special polymers, which are resistant to corrosion, mechanical impact, and chemical impact. This ensures that the bearings are uncontaminated and protected from wear.

Sealing Technologies progressed: SKF utilizes sealing technology designed to prevent contaminants from penetrating while securing the lube within the equipment. This maintains hygiene and minimizes the chances of contamination.

Temp endurance: SKF Bearings have been engineered to withstand tough operating temperatures in food-making processes, from high-temperature sterilization to low temperatures for storage, with consistent reliability.

New lubrication technologies: The application of self-lubricating materials decreases the reliance on external lubricants, which reduces maintenance and the risks of food contamination.

Marketing control: Sas every item has or can obtain certificates that confirm compliance with international food safety requirements and confirm control over many industry constraints.

In my view, these parameters are closely substantiated as making SKF bearings a competitively sound choice in food processing. They also help maintain high hygiene and reliability, which is critical for effective and safe operations.

Comparing SKF with Other Bearing Brands

From the statistics I’ve gathered about the three leading websites comparing SKF bearings with other brands, certain distinct features emerged. First, SKF’s focus on material science earns it a higher pedestal—stainless steel resistant to corrosion and polymers approved by the FDA for their application ensure a sturdy, reliable product for use in the food industry. On the other hand, some competitive brands may take shortcuts in materials with technological advancements to cut costs that may not withstand stringent regulations needed in food processing industries.

Also, on these pages, another critical argument that earns SKF another brownie point is its advanced sealing technology. It guards properly against any ingress of contaminants, which not all competitors can provide, thus causing possible contamination hazards. Furthermore, SKF bearings have fantastic temperature capabilities and can operate under various working conditions, unlike rival brands that might not work under a stressed temperature range.

Taking into account, for instance, self-lubrication technology, which is another technical parameter, affirms the dominance of SKF. Since it contains the requirement of secondary lubricants, this reduces the chances of contamination substantially. With this feature and complete mandatory certification of compliance with international regulations for food safety, it is evident that skf bearings are indeed market differentiators in terms of reliability, hygiene, and operation compared to many other brands.

What Makes Stainless Steel Bearings Ideal for Food Contact Applications?

Properties of Stainless Steel that Enhance Corrosion Resistance

In my analysis of the top three websites on the topic: ‘Properties of stainless steel contributing to the resistance against corrosion,’ I obtained several significant findings. With regards to the topic at hand, steel stands amongst the best options for corrosion resistance, which can easily be attributed to the fact that it contains chromium, which is essential as it develops chromium oxide, a type of passive film. Such a film can also recover quickly and provide adequate protection from corrosion, even in severe environmental conditions. Most websites point out other essential components, including Molybdenum and Nickel, which improve the corrosion and pitting resistance when added to some grades of stainless steel.

Furthermore, the technical parameters associated with the stainless steel bearings that warrant their application for food contact application include the following:

Content of chromium: Generally, chromium content is above 10.5%. This percentage is important since if it is low, a protective oxide layer cannot be produced, which is meaningful for corrosion prevention.

Increased information on the Addition of Molybdenum and Nickel: These factors boost the resistance to pitting, which is a great threat, especially where there are significantly high levels of chloride or acidic environments, which are usually experienced in planet food processes.

Surface characteristics: Finishing stainless steel bearings with a smooth surface helps lower the chances of corrosion initiation, which is enhanced further during food processing as there are hygiene requirements.

These factors together enhance stainless steel’s corrosion resistance, making it most suitable for use in food applications of bearings where both strength and protection of bearing materials from foodstuff contamination are very important.

Why Stainless Steel is Preferred in Washdowns

Through my research, I learned from the articles about the advantages of using stainless steel in washdown on Google’s first three web pages. It is common knowledge that stainless steels are used because of their excellent corrosion and chemical resistance, crucial during the arduous cleaning processes typical in a food processing environment. With the capability to endure numerous high-pressure washdowns with no degradation, stainless steel is a crucial contributor to upholding hygiene and safety requirements.

Some of such technical parameters include:

Corrosion resistance: Chromium in stainless steel helps prevent corrosion by providing a protective oxide film that makes its steel washdown resist harsh conditions.

Chemical resistance: Its ability to withstand the aggressiveness of washdown cleaning materials guarantees risk-free long-term performance.

Temperature tolerance: Stainless Steel’s ability to retain its shape and form during cleaning that involves hot water or steam is very helpful because, during these processes, it is common to find varying temperatures.

Smooth surface finish: The use of non-porous and smooth surface materials makes bacterial formation difficult and enhances cleaning processes. Therefore, sanitary conditions are guaranteed.

Because of these attributes, stainless steel washdown is the most widely accepted option. It meets high standards of cleanliness and performs admirably.

How Can Engineers Improve Food Safety with the Right Bearings?

Design Considerations for Food-Safe Bearings

Based on the evaluation of the three leading websites dedicated to food-safe bearings and their applications regarding food-safe bearings, a few notable patterns emerged that seem to matter in enhancing the safety and sanitization aspects of the product in the food sector. First, choosing options using materials that are rust-resistant by design, such as stainless steel, is crucial. This is supported by high amounts of chromium, which is responsible for oxide formation and is essential for processing in harsh environments. Equally critical is introducing self-lubricating components that eliminate the possibility of contamination due to lubricants, a common issue in food contact applications. Additionally, it is necessary to make bearings with robust sealing technology because it reduces the chances of contaminant ingress, hence offering additional protection against any potential food safety issues.

The technical conditions which reinforce these aspects are the following:

Material Selection: Use of stainless steel or polymers that are FDA-compliant and can resist environmental stress.

Sealing Technology: Provide appropriate seals to prevent contaminants and maintain hygiene.

Self-Lubrication: Self-lubrication methods decrease the necessity for external lubricant, reducing the risk of contamination.

Smooth Surface Finish: This aim is to provide a non-porous and easy-to-clean bearing surface, which is of paramount importance in preserving hygiene requirements.

Compliance and Certification: The bearings should be thoroughly examined and certified per international food safety norms.

The aforementioned design considerations, endorsed by such research and the opinions of leading industry practitioners, point out the key parameters that engineers need to observe to ensure food safety and enhance bearing operating efficiency in food processing conditions.

The Impact of Bearing Failures on Downtime and Food Safety

Having reviewed the top three Google sites on the implications of bearing faults, I highlighted several important issues about the sustenance of downtime and food safety. Indeed, bearing faults can result in unplanned out-of-operations time, resulting in deviations in production plans and many other expenses. As a result, there are common causative aspects, such as insufficient lubrication, shaft seal failure, and material wear, which result in bearing screwing abuse.

Within the food chain’s context, bearing failure might result in bearing parts or lubricants getting into the food and causing contamination. Also, replacing those failed bearings can incorporate foreign materials into the production environment if adequate measures are not put in place, increasing the standards of hygiene.

To tackle these concerns, it is vital to understand the following technical parameters:

Lubrication Systems: The use of reliable self-lubricating bearings eliminates the need for external lubrication, decreasing the chances of contamination to zero.

Robust Seal Design: Employing seals that can endure excessive amounts of environmental stress stops substances from reaching bearings and damaging the seams.

Materials Engineering: Employing superior materials with anti-fatigue and anti-corrosive properties, such as alloys, can increase the service life of these bearings and reduce the instances of failure.

Monitoring and Maintenance Practices: Systematic condition monitoring makes it easier to detect early signs of wear and, hence, take remedial action to avoid unforeseen breakdowns in the future.

The need to provide these factors is attributable to the fact that they will cumulatively improve bearing reliability, reduce failure incidences, and guarantee uninterrupted and safe food-processing operations.

Strategies for Selecting Corrosion-Resistant Bearings

Considering food processing applications susceptible to corrosion, I researched the attainable bearings on the first three pages of Google search engines, which enabled me to grasp better practices and the relevant technical parameters. The underlying strategy is to use materials that have protective features, such as stainless steel or coated metals. Such resistance is essential in protecting the materials from further deterioration since there are high chances of exposure to moist and chemical environments.

A significant aspect is the advanced sealing systems that have been developed and incorporate features such as barriers to corrosive elements and potential contaminants. Self-lubricating mechanisms, however, are favorable in terms of decreasing the dependence on external lubrication, thus eliminating one source of potential contamination associated with lubricant leakage.

The technical parameters which are consistent with these strategies include:

Material Quality: Stainless steel or corrosion-resistant alloys, of which the two have proven longevity.

Sealing Efficacy: Seals combat environmental contaminants and withstand maximum protection.

Coating Techniques: Enhanced coated surfaces for corrosion protection that are also wear-resistant.

Operational Temperature Range: Low or high-temperature bearings are made to withstand extremes without affecting material properties.

Certification and Compliance: All bearings selected comply with applicable corrosion standards.

Choosing the right bearings that meet the above criteria allows me to perform to the highest level, even in adverse conditions, without compromising system performance, hygiene, and safety. These valid strategy studies demonstrate the effective implementation of multi-faceted solutions for corrosion protection and the prolonging of bearing service life within the food processing industry.

Frequently Asked Questions (FAQs)

Q: What food-grade bearings are, and what advantages do they have in the food industry?

A: Food-grade bearings, such as ball bearings, roller bearings, etc., are designed for machinery that directly or indirectly comes into contact with food. Such bearings are made from stainless steel and food-grade lubricants to be corrosion—and contamination-proof, which is vital for food safety and quality. They are critical components of machines in food processing, while beverage and food-grade bearings assist in limiting upkeep time while promoting safety.

Q: Why is it critical to use H1 food-grade bearings in the food industry?

A: Non-food grade bearings cannot be used in the food industry. The lubricant used in these bearings is non-toxic, compliant with NSF H1 standards, and safe for food even when it is in contact with food. Also, these bearings are meant to meet the heavy requirements in the food and beverage industries.

Q: What bearings may be employed in the food processing industry?

A: The types of bearings employed in food processing include deep groove ball bearings, spherical roller bearings, and other food-safe bearings. These bearings have been made to meet the demands of food and beverage vibration, corrosion, and contamination challenges while sustaining the machinery’s functioning.

Q: What is the significance of employing food-grade lubricant in the bearings used in the food industry?

A: Food-grade lubricant is important because it reduces the probability of contamination of the food product. In situations where the bearings can be exposed to food or food products, it is a prerequisite to use food-grade lubricant such as NSF H1. This is so that in the event that a lubricant spills over into food, it should be safe and not endanger food safety.

Q: In what ways can the size of a bearing assist in its functioning in the food industry?

A: A bearing’s size is important in its strength rating and speed rating, which are critical in applications such as the food industry. The correct size is selected so that the bearing will not fail at operational demands, reducing maintenance and downtime of food and beverage facilities.

Q: How are bearings significant in machines in processing food?

A: Bearings perform fundamental operations in machines used in food processing by ensuring the efficient and smooth operation of the machine parts. They reduce friction between moving parts, minimize wear and tear on machines, reduce energy consumption, and improve machine lifespans. There are also food bearings designed to resolve the peculiar aspects of food processing activities.

Q: How do food-approved bearings enhance the green agenda of processing food?

A: Food-grade bearings enhance the green agenda because they do not require frequent replacement and repairs, are durable, and can withstand harsh environmental conditions. Edible bearing grease and bearing housing materials ensure that any waste produced is environmentally friendly, thus practicing green in food and beverage facilities.

Q: What advantages are derived from using spherical roller bearings in the food sector?

A: Spherical roller bearings are advantageous in the food industry as they can tolerate misalignment, carry heavy loads, and are strong and solid. These qualities make them suitable for use in various situations where equipment experiences shock and heavy work, thus making their operation reliable and maintenance minimal.

Q: What is the basis of the ability of food-grade bearings to tolerate standard cleansing procedures?

A: Food-grade bearings can tolerate standard cleansing procedures because they are made of stainless materials and food-grade lubricants. These parts are built to protect against the eroding nature of water and cleaning substances, usually in the food and beverage plant, enhancing their durability and effectiveness.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8