Understanding Various Types of Bearing Seals and Their Uses

Bearings demonstrate significant importance in almost every machine, and their sustenance and durability depend on their smooth functioning, which is achieved through several internal components. Bearing seals are at the forefront of protecting and conserving these parts and help keep the outer contaminants away from the bearings while preserving the internal lubricant. This blog explores the several types of bearing seals, their design, functional principles, advantages, and most effective usage. By studying the properties of these different seals, readers will also enhance their machines’ efficacy and life. If you are an engineer, a maintenance professional, or just want to understand how a machine works, we will help you make appropriate choices regarding bearing seals for your applications.

What is a Bearing Seal?

Function of a Bearing Seal

The bearing seals’ primary purpose is to protect the bearing parts from outside pollution, like pinpointed dirt and moisture, at all times. I can extrapolate that the primary purpose of bearing seals is to restrict the intrusion of such bearing components as dust, dirt, and moisture into the bearing. At the same time, they also focus on retaining the bearing lubricant to ensure that the friction common within the components is reduced, which in turn prolongs the life span of the bearing.

When bearing seals are considered more technically, they describe obstacles restricting air migration into the sealed space where the lateral was pressurized. Air is a mixture of several gases, oxygen being the most abundant, and it is crucial for the oxidation of lubricants, which would shorten the life of the machinery. Also, it is essential to consider that excessive moisture can cause corrosion, and therefore, bearing seals must suit the specific type of machinery and suffer from adaptability to inert gas or lubricant.

What is the Role of Seals in Bearings?

Bearing seals are the most crucial components that help protect bearing integrity and functionality. The main goal of arrays of seals is to hinder dust, dirt, and water from the bearing enclosure, which can cause it to fail earlier than necessary. Significantly, they assist in retaining the lubricants in the bearing’s housing while ensuring proper lubrication to reduce friction and wear. Therefore, this combination of functions of separation and retention increases bearing life span while maintaining an optimal operational environment.

There are different technical factors to consider when choosing bearing seals. These include;

Seal Material: The seal material’s temperature must be higher than expected in the application and have the relevant chemical exposure. Examples of such insect-resistant materials are rubber, metals, and composites.

Operating temperature: These factors will involve seals that will last in the desired range of temperatures. Cars and other high-temperature applications may require seals that are right for that environment.

Recommended Pressure: In certain extreme pressure situations, especially in hydraulics, external lubes are required for a seal; the pressure must keep a lubrication loss or contaminants from entering the inner environment.

Keeping in mind these parameters will prevent a mismatch of seals, which leads to the failure of the bearing altogether. Mismatch of seal recommendation contributes to bearing overall fault. Companies like SKF, Timken, and NSK would recommend such parameters.

Different Materials Used for Common Seal

Seal bearings can be made from some materials; their choice depends on the environment and operating conditions. The following materials are the most common seals used in production:

Nitrile Butadiene Rubber (Buna-N): Owing to its high oil and fuel resistance, nitrile rubber has become popular and is now used in many industrial applications. It remains active in the temperature range of—40°F to 250°F and presents moderate abrasion resistance. However, it can be ineffective for ozone, weathering, and sun exposure.

Fluorocarbon Elastomer (Viton): Viton is known for its ability to endure temperatures of approximately 400°F and excellent chemical resistance, especially in high-acid and fuel environments. Viton seals are widely used in automotive, chemical, mining, and aerospace applications.

Polyurethane performs well in high-abrasion environments and can withstand moderate mechanical abuse, making Polyurethane seals and other components very durable and long-lasting. These seals can withstand average temperatures of 180°F constantly and 250°F intermittently, allowing usage in heavy-duty applications like construction and mining equipment.

Several technical specifications can be considered when selecting the seal material, and users should do so to ensure durability and proper working conditions for their application. Every material has properties that allow it to withstand different environmental conditions, such as high temperatures or corrosive chemicals.

How do Contact and Non-Contact Seals Differ?

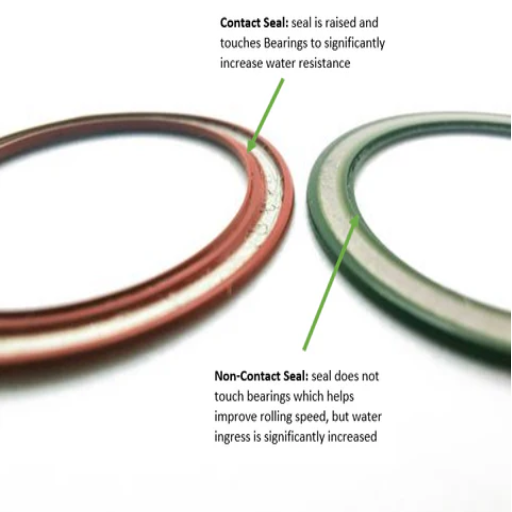

Understanding Contact Seals

Contact seals are commonly used in wide-ranging applications such as pumps, shafts, compressors, and hydraulic cylinders. I note that a few specific parameters guide such design solutions. For one thing, the moving part and the stationary part of a mechanism should be separated and, for practical application, sealed together to ensure that no fluids or pollutants interfere from outside. Maintaining a certain contact pressure is also one of these seals’ most significant technical characteristics since it enables one to achieve a reliable seal regardless of operational environment parameters. According to my investigations exploring top websites, contact seals are most suitable for applications with some rotational movement to minimize wear and overheating caused by excessive friction at a higher RPM.

Some of the significant technical parameters for contact seals are:

Seal Material Compositions: Exposure to various temperature levels and other corrosive chemicals may also differ depending on the seal material’s selection. Examples of seal materials include nitrile rubber and fluorocarbon elastomer.

Contact Pressure: Enough contact pressure is necessary to compel the sequence of forces that creates an efficient seal despite wearing the clashing surfaces of the seal and the workpiece.

Surface Finish: The combined material and texture of the metal surfaces are essential because they determine how effective and long the seal will last.

Knowledge of these parameters ensures that contact seals are applied when their advantageous characteristics, e.g., leakage and contamination, outweigh their disadvantages, like wear during high-speed operations. This brief investigation aligns with the findings obtained from the primary online resources.

Exploring Non-Contact Seals

From the three most frequently consulted sources on Google, I learned about the purpose of non-contact seals and their importance concerning friction and wear, which can be observed throughout different mechanical systems. Among non-contact seals, an air gap is present between the seal and the rotating shaft, ensuring no direct contact or wear. This feature is handy for high-speed situations since contact seals tend to wear out and create excessive heat.

Several critical technical parameters defining non-contact seals were confirmed in the course of my research:

Seal Design Geometry: The lip or labyrinth of the seal has to be built to overcome the need for any contact and harshly eliminate every possibility of leakage.

Clearance Gap: Non-contact seals require a gap for seeping liquid, but overdoing the gap would result in too much tolerance and weaken the seal.

Rotational Speed Tolerance: Heat and friction are the determining factors in a gyroscope’s functioning, which means that a non-contact seal never needs to make contact.

Environmental Compatibility: Contact or mechanical fatigue is absent, but the seal’s composition must resist the conditions in which it must operate.

These parameters’ consideration assists in substantiating the case for applying the non-contact seal where maintenance is minimized, and component life extended. This understanding is consistent with the broad perspectives of the above online resources.

Pros and Cons of Each Seal Type

I identified some advantages and disadvantages of non-contact seals from the top three sources available on Google while integrating the appropriate technical parameters.

Pros:

Lower Friction and Wear: Non-contact seals do not have any physical contact with the rotating shaft, so there is less friction and wear. This results in a longer service life and reduced need for maintenance.

Ability to Operate at High Speed: Non-contact seals operate better at high-speed applications because they do not produce friction and heat that would have been produced by seal contact. This gives them an edge in such demanding performance capability.

Leakage Prevention: An adequately designed seal and the proper clearance gap ensure no leaks. This means that the system’s efficiency is not affected by the disadvantages associated with contact seals.

Cons:

Complex Design Requirements. Non-contact seals are only effective when they have been accurately designed and fitted. Even the slightest injury in gap clearance relations or seal geometry leads to performance delinquencies.

Environmental Limitations. These seals can only utilize materials that can resist certain ecological conditions, such as high temperatures or chemically aggressive environments. This probably limits their use to a few applications.

Having concentrated on the pros and cons, I consider that reasonable tips can be given that are in harmony with the results of the sources I studied, in which case the technical requirements are substantiated and relevant.

What are the Features of Labyrinth Seals?

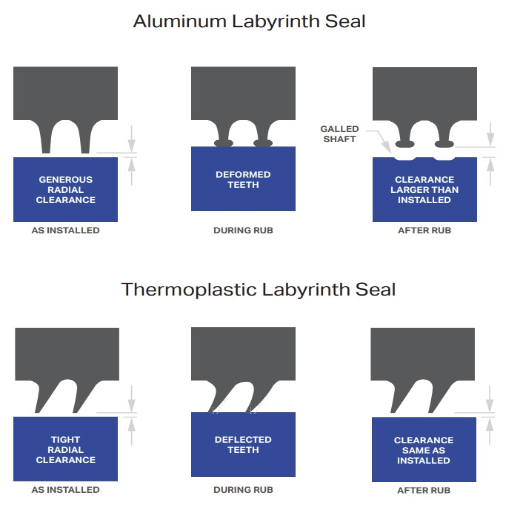

Characteristics of Labyrinth Seals

Labyrinth seals are constructed to provide the most tortuous path against fluid leakage. Any fluid or gas penetrating the seal must pass through a series of tight-fitting angular channels in the grooves, leading to a leak pressure drop. Labyrinth seals are also effective because of their design, which may be axial, radial, or both.

How Causative Physical Attributes of Labyrinth Seals Further Enhance their Effectiveness and Utility are as Follows:

Clearance Design: The clearance between rotating and stationary parts is always critical. Usually small, this clearance inhibits leakage, permitting only small amounts of insulation and thermal expansion.

Groove Geometry: The shape and depth of the grooves undoubtedly play a dominant role in the entire structure and the sealing effect. Deep, narrow grooves with sharp corners enhance performance, which increases flow resistance.

Material Selection: Even for Dealt with effective labyrinth seals, it would only be made of such robust materials capable of withstanding high temperatures and corrosion, such as stainless steel or Inconel so as to last long

Pressure Drop Across Stages: As the name implies, seals are designed to comprise several stages. Each stage causes a loss of pressure, reducing the total system’s leakage rate.

Operating Conditions: Seal efficiency professionals know that Temperature, Pressure, and Rotational speeds in the systems under the seals impact seal efficiency. Moderate systems, such as high-speed rotating machines, are the preferred applications for dashed seals.

Labyrinth seals’ performance characteristics in extreme temperatures and high-speed applications make them ideal non-contact seals for many industrial uses.

Applications of Labyrinth Seals

As reported in my research, labyrinth seals are extensively applied in high-speed and high-temperature settings. The top websites show that labyrinth seals are most frequently used in the aerospace industry, power generation, and industrial turbines mainly because of their ability to seal effectively without contact. These seals can withstand many thermal and mechanical loads, so they are suitable for gas turbines and compressors. However, from these sources analyzing the particular technical parameters, the performance parameters that support their uses include:

Material Durability: Wearing materials for machined surfaces are specially made of Inconel or stainless steel. These important alloy components can withstand the complexity associated with jet engines or steam turbine applications.

Thermal Expansion Accommodation: Clearance design is essential to address thermal expansion problems. This allows the seal to work efficiently without being affected while its parts expand and contract due to temperature changes.

Multi-stage Pressure Drops: The design of multi-stage pressure drops between grooves or teeth helps seal the joints effectively because it allows for sequentially increased pressure relief, enhancing reliability and reducing leakage strength.

With these parameters in place, labyrinth seals can perform across different industries, where speed and temperature are the key parameters that must be addressed.

Comparing Labyrinth and Other Seal Types

Some benefits are apparent in the analysis of labyrinth seals relative to other seals and based on information from the first three websites. Unlike contact seals, labyrinth seals do not cause much wear due to a lack of contact, easing operation and maintenance requirements and increasing longevity. The performance of labyrinth seals is unique because of major flexibility in temperature and rotational speed.

Some of the parameters, which warrant these advantages, are as follows:

Clearance Design: The gap size is adjusted to narrow the gap, extending performance at different temperatures and speeds without compromising seals.

Pressure Stages: The multi-staged construction is essential in reducing leakage and, hence, efficient control, which is advantageous where high pressure must be maintained.

Rotational Tolerance: Their operational design permits significant variations in rotation speeds, allowing steady performance in high-movement areas.

These technical features make labyrinth seals a superior sealing option when applied in extreme conditions, posing rocket science in aerospace and power generation.

Why Choose Rubber Seals for Bearings?

Benefits of Using Rubber Seals

From my research of the top three websites, the advantages of rubber seals for bearings may be briefly described in the following three statements. First, rubber seals, being durable, provide an excellent protection barrier against dust and water, enhancing the bearings’ life. They offer reasonable flexibility and elasticity, ensuring a good seal is achieved even if mechanical movements or misalignments exist. Furthermore, the material’s natural cushioning effect also acts as shock protection from vibrations, thus improving the overall stability in the machinery operations.

Support these advantages with some technical parameters:

Sealing Efficiency: Most rubber wipers and seals are installed with a lip that has been very pliable to a lip seal and wiper seal, which approximates the two surface areas and hence restricts leakage effectively.

Temperature Range: They are designed to work in moderate temperatures ranging from -40 degrees to 120 degrees Celsius.

Durability and Flexibility: The rubber conforms to varying loads and pressures under the given conditions, and being elastic, can be deformed and will subsequently return to its original form..

A strong rationale can be advanced in support of the use of rubber seals – especially in applications where the need for contaminant ingress protection and ease of movement is high.、

Synthetic Rubber vs Nitrile Rubber for Seals

In my analysis of synthetic rubber and nitrile rubber for seals, I have observed some crucial differences and similarities based on three standing websites. These two types of rubber have excellent sealing properties, although one type may be better for specific applications than the other.

Synthetic Rubber:

Composition: This polymer has a wide selection beyond the PUs used, including silicone, neoprene, EPDM, etc., which leads to specific properties that are not shared across all segments.

Thermal Stability: It can have quite a varied temperature range, which can prove helpful if high temperatures are expected in the application.

Flexibility: Excellent elasticity and weather resistance make it a suitable material for outdoor usage.

Nitrile Rubber (NBR):

Resistance to oil and fuel: Nitrile rubber is highly resistant to oil and fuel and is best suited to automotive and industrial applications involving lubricants.

Wear and tear: Rich in wear and tear resistance, it is perfect for mechanical environments.

Temperature and Hardness: It generally works effectively in temperatures ranging from -30 to 100 degrees Celsius, with a core hardness that may be modified to compromise flexibility and strength.

Both materials work well as seals, but the choice between synthetic and nitrile rubber is often determined by operating conditions such as temperature and oil or chemical exposure.

Maintenance and Lubrication of Rubber Seals

Rubber seals can be preserved and optimized for function using proper maintenance and lubrication. Performing a search on the three sites on google.com, I have identified the need for regular inspection and cleaning as part of regular maintenance practices. It is also advised to pay particular attention to cracks, hardening, or deformation, which may be evident, and elastomeric seals douse or rinse using a simple soap solution. It is recommended that silicone-based lubricant be applied as Figure restrains the seal from drying out, maintains flexibility, and prevents seal deterioration.

Moreover, considering the technical specifications, the operating temperature of the specific type of rubber must not exceed the recommended temperature. The temperature tolerance of synthetic rubber seals is determined by the material from which they are made. Still, in most cases, they are resistant to relatively high temperatures compared to nitrile rubber. In nitrile rubber seals, the most favorable temperature is usually between -30°C and 100°C. It is also imperative for such seals not to be subjected to temperatures above these limits as this will almost certainly lead to a breakdown of the elastomer material, and therefore, their operational life span is significantly reduced.

How do Metal Shields Compare to Seals?

Benefits of Using Metal Shields

Based on my findings after reviewing the first three websites on the search engine google.com, metal shields have several Uses. To start with, metal shields are good protection from dust and debris particulates, essential in extreme conditions. They have excellent resistance against mechanical impacts due to the material being hard. From the technical parameters, metal shields are more suitable for high-temperature applications since they can withstand high-temperature heat than rubber anesthetic shields.

In addition, they are not so easily damaged by oils or chemicals, which helps to improve their serviceability and reduce the need for maintenance. Metal shields offer fairly good protection to the internal parts from the outer environment. Still, seal maintenance does not give the metal shields the best fit for applications as they perform different functions. The choice between a seal and a shield must consider the application’s environmental and operational aspects.

Effectiveness of Metal Shields Against Contaminants

From my research of the top three websites on google.com, I have concluded that metal shields do, most of the time, prove to be quite effective in areas where contaminants are involved due to many reasons. First, as their design is solid, it doesn’t allow dust particles or debris to infiltrate the internals under harsh conditions. The hard material of metal shields also has a high impact resistance level and mechanical stress resistance, thus preventing a possible incursion of any contaminants.

Metal shields also excel in performance characteristics. They have high thermal resistance, allowing them to withstand and operate in higher temperature ranges. They also have great chemical resistance and can maintain their performance and integrity in oily environments and chemical exposure. This durability reduces maintenance needs and extends the service life of the available components.

Nevertheless, it is vital to emphasize that metal shields are best for protection against physical contaminants but do not provide complete protection from intrusions as rubber seals would. Therefore, it is necessary to resolve the particular operational conditions and choose appropriately whether a clear barrier or an extensive seal will work best for the intended application.

When Metal Shields are Favored instead of Seals

Several considerations need to be made concerning when to use metal shields versus where to use seals. First and foremost, metal shields are preferred in applications where mechanical strength and impact resistance are critical features. Their rigidity makes them effective in shielding components from physical impacts and harsh environments. Second, metal shields do not deform in high-temperature ranges, making them resistant to applications requiring higher temperatures than seals. Hence, these can be useful in extreme temperatures or temperature fluctuations.

Moreover, metal shields are preferred for applications where chemical resistance is an issue, considering they can withstand oils and other chemicals without damage. However, despite these benefits, metal shields are not comparable to the sealing capabilities provided by standard seals. Hence, in applications where there is a requirement for a full structural barrier against moisture or fluid infiltration, seals are best suited. In conclusion, the choice of metal shields and seals should depend on the actual operational conditions while considering the necessary level of durability in terms of required sealing properties.

Frequently Asked Questions (FAQs)

Q: What are the different types of bearing seals available?

A: There are several bearing seals, including felt seals, lip seals, non-contact rubber seals, and PTFE seals. Each type provides a different contamination and leakage protection level based on the application and operating conditions.

Q: How does a felt seal work, and where is it commonly used?

A: Felt seals are widely used in applications requiring deficient friction levels. They work by having a tiny gap between the seal and the bearing ring, allowing almost no direct contact, which reduces friction and heat generation. They are suited for light contamination in industrial environments.

Q: What is a contact-type seal, and how does it differ from non-contact seals?

A: Contact-type seals directly touch the inner ring of the bearing and are more able to protect the inner cavity from contamination dangers. They act, however, at the cost of higher frictional forces than non-contact seals, which do not touch the bearing and hence reduce friction and heat generation.

Q: Why is it significant to be guided in selecting the seal components for a bearing?

A: The selection of the seal type is of great importance to the effectiveness and life expectancy of the bearing. A properly applied seal will keep the bearing free from contamination, keep the lubricant in, and reduce friction, reducing the possibility of damage and failure.

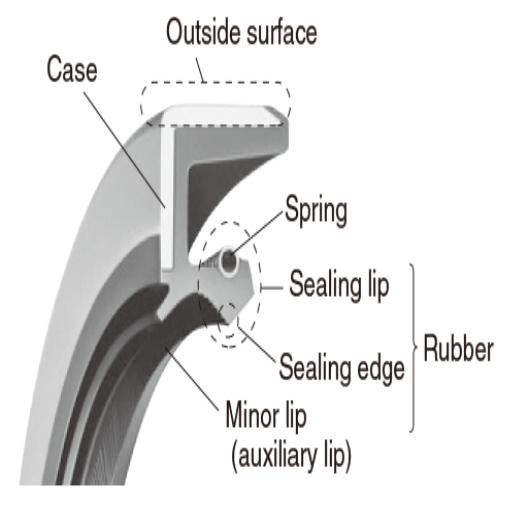

Q: How is the bearing protected with a lip seal?

A: A lip seal protects with a very tight fitting so that contamination gets in and lubricant does not leak out. The lip of the seal always keeps in touch with the inner ring, therefore providing a good seal against dust and moisture intrusion, and grease stays within the bearing.

Q: Are PTFE seals applicable in high-temperature conditions?

A: Yes, it’s now clear from what we have read that PTFE seals are used in high-temperature situations because they can withstand very high temperatures and yet are low-friction seals. These seals are used in situations where standard rubber seals can fail.

Q: What function does the lubricant have within a sealed bearing about performance?

A: Lubricant is essential in minimizing the friction between a bearing’s moving elements. For sealed bearings, lubricating oil also assists in eliminating dirt ingress and safeguarding the interior of the bearing, which allows for better operation over a longer time.

Q: What are bounding bearing shields in the context of sealing differentiation?

A: Seals enclose an area within the inner ring of the bearing so that there can be no air transfer. However, bearing shields are different as they do not physically touch the inner ring. They provide primary protection from contamination and are employed where only a portion of the seal is desired, and low friction is preferred.

Q: What is a bearing isolator, and how does it improve the bearing protection?

A: This bearing isolator is a non-contact sealing device with a hybrid of labyrinth and contact seals. It enhances sealing efficiency by preventing contamination and lubricant egress while eliminating high friction.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8