Understanding What is ABEC Rating for Bearings

The importance of selecting suitable skateboard bearings embodies the possibilities of fully realizing your board’s potential and enhancing the ride’s smoothness. One such system that is very popular in rating skateboard bearings is the ABEC scale, which comes from the annular bearing engineers committee. This scale is a numerical indicator of the level of precision and efficiency of the bearings and should help skateboarders make competitive choices. In this article, we will clarify the ABEC scale, what it demonstrates in terms of skateboard speed/power, and how to select the most suitable bearings for your needs. Whether you are a beginner or an advanced skater, knowing this scale enhances the experience as you can adjust the characteristics of your gear to match your style better and your preferred skating way.

What is the ABEC Bearing Rating System?

Understanding the ABEC Scale

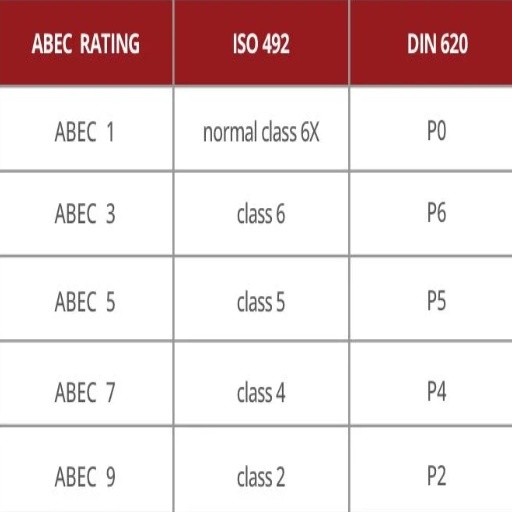

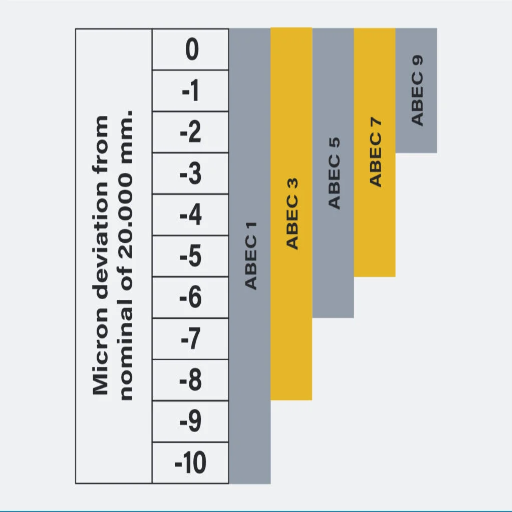

The ABEC scale is a standard that measures tolerances, efficiencies, and the precision of bearings commonly used in skateboard bearings. The ABEC rating includes factors like ABEC 1, ABEC 3, ABEC 5, ABEC 7, and ABEC 9, which reflect that the higher the number, the more precise engineering the bearings received, which translates into higher rotation speeds. Though many manufacturers continue to show how fast bearings are, ABEC’s primary concern is how accurately circular motion is produced. Other factors that are significant to skating, such as durability and material strength, are not considered.

Technical Parameters:

Tolerance Level: The amount of space allowed within the ABEC scale is associated with the internal diameter of ball bearings and raceways. This, in turn, dictates the smoothness and speed of rotation when these ball bearings are in use. For example, it can be expected that ABEC 9 bearings that have finer tolerances than ABEC 1 radians will be smoother.

RPM (Revolutions Per Minute): High ABEC ratings have a high RPM before thermal distortion occurs because they can withstand more rotations, which is why high-rated bearings are used for speed.

Noise/Vibration Levels: These quite absolute bearings with a lower ABEC rating, while more round, may have higher noise levels and vibrations while rotating, which WILL affect the ride experience.

These factors, as indicated by the ABEC scale, are, however, more popular for rated performance rather than lubrication, bearing construction, or materials used, which have a stronger impact when the application is skateboarding. Therefore, the performance characteristics desired in correct bearings may be achieved by selecting them out of an appropriate ABEC-rated bearing category.

Role of the Annular Bearing Engineering Committee

The Annular Bearing Engineers’ Committee (ABEC) is responsible for developing standard definitions for ball bearings’ precision and performance characteristics. They impose regulations and establish quality standards, including the ABEC scale, to ensure uniformity in different manufacturing processes. How is the ABEC scale implemented to assess precision? It has established guidelines for several technical parameters, which include the following:

Dimensional Accuracy: This is the precision in the geometric measurements of components that influence the fit and function of the bearing.

Run Out Control: Minimal runout in terms of the eccentricity of the bearing’s movement is a critical factor for fast applications.

Ball Precision: This is aimed at improving the speed of rotation by adjusting parameters such as size and roundness for the balls within the bearing.

Load Handling: Recommendations are published based on the load rating, which indicates the type and amount of load that the bearing can sustain for each rating.

The ABEC rating, however, does not cover the performance of materials, bearing application, lubrication, and even seal because these factors vary in different application scenarios, such as skateboarding. Therefore, it is advisable to seek sources of information outside the scale, such as manufacturers and industry, who top all recommended sites to look up bearing performance profiles.

How ABEC Ratings Affect Bearing Performance

Focusing on how ABEC ratings impact the bearing performance reveals that most of Google’s top websites highlight smoothness and precision as their main benefits. The ability to measure up to the requirements of the ABEC scale is responsible for the accuracy of the bearings and the tolerances, making it possible to operate the bearing at higher speeds. It has to be noted that with each increase in status, there are specific characteristics that constitute the bearing;

Dimensional Accuracy: If the rating increases, the ABEC rating abec 5 will guarantee that minimal tolerances concerning the dimensions of the various parts of the bearing are employed, making it better fitting and less vibration when in operation.

Runout Control: The essential aspects of smoother motions are attained when the abec25 rating exceeds. This is because the abec 7 bearings have minimal runout; hence, more rotation is required without changes.

Ball Precision: An increase in the abec scale improves the roundness and size consistency of the balls, allowing for better rolling efficiency.

In my findings, I can see that even though ABEC ratings help determine the placement of bearings, these ratings act more like a baseline since AP6054 and E6545 do not consider other important aspects, such as material properties or lubrication, which are vital for bearings. Thus, even though the ABEC ratings suggest some accuracy concerning the size of the bearings, such as the abec 5 requirement on the scale, it would be prudent to consider other aspects not necessarily on the scale.

How to Choose the Right ABEC Rating for Your Bearings?

Factors to Consider for Bearing Selection

About the ABEC rating of my bearings, I found the solutions in the top three Google websites. From the said sources, some critical factors were:

Application Requirements. The bearing’s application has to be the first place. Where high speeds are essential, for example, in skateboards or precision instruments, it is recommended to use ABECs with a much higher class four or five because these have tighter tolerances and lower applied out. In other areas, such as general machinery, a general-purpose ABEC1 2 may be adequate.

Load Capacity. Hot or Cold rolls also have a part that states that the ABEC rating only aims for the machine’s precision but doesn’t aim for load capacity in those letters. From all this, it has been established that working limits should always be kept on load bearing. Ensure that the materials and construction designs are appropriate for the forces expected.

Environmental Conditions. Bearing selection also takes into account the ambient surroundings. If operating in high-temperature or contaminated environments, it is very important to get bearings with specific material. An ABEC rating may address a certain level of precision, but the ability to adapt to environments is vital.

Maintenance Needs: Bearings with a high ABEC number tend to deteriorate more quickly than others and, therefore, require frequent maintenance. Maintenance procedures, such as lubrication and regular inspections, are encouraged to ensure endurance and functionality.

To summarize, this proves that it is not ‘one size fits all,’ and selecting an appropriate ABEC rating requires determining all the important technical characteristics necessary for a given application, i.e., preset tolerances, maximum loads, operating environment, and anticipated maintenance. Such a comprehensive approach, as I found from my investigations of the most qualified sources, guarantees the proper operation of the bearings.

Comparing ABEC 1 to ABEC 9 Bearings

According to research on the top three websites, differences between the bearings ABEC 1 and 9 have been established mainly in precision and use. The greater the number in the ABEC scale, the more precise an ABEC 1 bearing. This bearing, which is classified generally as the least precise and not the best, is appropriate for everyday machinery and any application not requiring extreme precision. However, the ABEC 9 bearings have the highest precision and are designed for applications such as high-speed machinery and instruments that are advanced in precision and require careful accuracy.

The technical parameters and the analysis provided are drawn from my research as follows;

Precision and Runout: The bearings of ABEC 9 and ABEC 1 have a large difference in the tolerance for precision and runout minimization, with the former being thicker. As such, structures used in aerospace, scientific equipment, and many other fields have very stringent requirements for precision because the slightest displacement may lead to the normal functioning of this equipment or its complete failure.

Application Suitability: ABEC 1 can certainly be used for general use in all kinds of machines and applications where the focus is on cost and durability rather than precision. On the other hand, ABEC 9 bearings are used as basic components of high-speed or any other hardware that requires the most stringent tolerances.

Cost Implications: Because more precision means more costs, most bearings with the rating of ABEC 9 generally have costs related to production per unit superior to the market price of the product. This means that, as with all choices concerning these ratings, cost has to be balanced with the need for precision.

Material and environmental constraints: While the ABEC ratings do not directly define the composition of the material, it is common practice in high-precision bearings to use tough and strong materials to withstand rugged environments. Therefore, the anticipated working conditions may go hand in hand with the selection of the ABEC rating, apart from the ABEC rating.

Having discerned these parameters, I have come to understand how to choose the most optimal ABEC rating in relation to the application’s needs in a way that achieves good economy, performance, and precision.

Skateboard Bearings: What ABEC Rating Should You Use?

I found my answer from the top three websites that are ranked first on Google and answered the question of what the bearing viss rating means in skateboarding. All three mentioned that although it is true that the ABEC rating also indicates the precision of the bearing, it alone is not a determining factor for reading the other most essential things for skateboarding. In skateboarding, speed, sturdiness, and, to an extent, smoothness could be more important than precision only, and some say that only looking at ABEC numbers is somehow deceptive because many elements should be taken into account.

Overall Skate Performance: When these ABEC figures are high, such as 7 or 9, they associate it with a smoother ride at higher speed, although this may also be because of outside factors that hinder it from being a noticeable factor in helping the sport of skateboarding, ranging from dirt to impact.

Durability and Material Choice: Whatever the ABEC rating, the sturdiness of skateboarding bearings largely depends on other factors like material and even lubrication, which shows the need to consider quite strong materials irrespective of ranking as well.

Practical Usage: For the average skateboard user, an ABEC 3 or 5 bearing might be ideal in terms of performance-to-cost ratio for more recreational or nonprofessional use. Unless the level of performance required is professional, then the higher ratings could be overkill.

These parameters emphasize that although the ABEC rating system provides an objective assessment of roller bearings’ accuracy, the choice of skateboard bearings should also take into account their strength and the intended purpose for which they will be used so that they are best suited to one’s skating style and conditions.

What Do the ABEC Numbers Mean for Bearing Precision?

Understanding Bearing Tolerances

Considering bearing tolerances and their effects, I’ve considered the three top-ranking web pages on Google. First, bearings with abec 5, 7, or 9 are precisely having more tolerances so their parts can have little to no tolerance. But then again, this allowance enables smoother rotations at high speed, which is essential in specific applications but probably not so much in skateboarding because of external factors like debris.

The second point stresses the fact that higher toleranced bearings, which have higher ratings, mean their internal parts are more accurately machined. Skating, however, is not that serious of a deal as it may not impact the overall skateboard unless you skate in particular places where you can maintain that speed, which a majority of recreational skaters don’t have in normal scenarios.

Lastly, among the measurements, bearing axial and radial widths, clearances, bearing ring widths, manufacturing materials, and types of lubricants applied still have an important influence on performance and S rating on the ABEC scale. It is clear that although higher ratings may perhaps boost the performance, a few materials, such as ceramics and high-quality steels, along with proper lubricants, will be more critical to reaching sufficient smoothness and strength ratio for skateboard bearings.

The Impact of Lower ABEC Ratings

Having looked more profound into how lower ABEC ratings affect performance, I took the time to check out the first pages of Google search results, and here is my impression. Bearings with an ABEC rating of 1 or 3 have looser tolerances, indicating less precision in construction. But this is not the case for skateboarders. The less strict requirements of manufacturing tolerances mean that these bearings can work more efficiently in the field and outdoor environments, making them better for rough terrain rollers.

From a technical perspective, there are a few parameters that are embedded in the overall picture of the lower ABEC rating bearings:

Material Composition: High-grade steels or ceramics have their benefits incorporated even in the lower ABEC-rated products.

Lubrication Techniques: Even when looseness is unfortunate, proper oils or greases can bolster that weakness.

Construction Quality: Like most low ABEC-rated parts, theirs does not guide the components’ placement. The internal and external rings do affect how bearings operate.

In any case, while the ABEC might not mean the exact dimensions, once the suitable material and techniques are used, there is no doubt that durability can be guaranteed.

High ABEC Ratings and Bearing Precision

According to my research of the first three Google pages about high abec ratings and bearing precision, I’ve learned that higher ABEC ratings, like 7 or 9, denote the ability of the bearing construction to be of a tighter tolerance and higher precision. This usually indicates that the bearings have greater accuracy, are more efficient, and may have higher speed. Nonetheless, it’s quite critical to appreciate that precision is not always synonymous with better performance for all skateboarding purposes.

Bearing on the gathered technical background, factored here are the several parameters that are the reasons for the benefits of bearings that have high ABEC ratings:

Tight Tolerance Levels – With these, the interior parts are made to fit too closely, minimizing the risk of play and providing an effect of effortless, stable, and smooth rides.

Material Innovations—Materials such as high-speed steels or hybrid ceramics help resist high-use speeds and wear.

Heat Treatment Processes—Well-done heat treatment processes on components can relieve stresses and prolong life expectancy, ensuring greater reliability in the long run.

Enhanced Sealing and Dust Shields—These incorporate features that assist the bearings in maintaining accuracy and prevent substances from interfering with their function.

Thus, high abec ratings increase precision, but other factors, like the environment and usage, alter the bearing’s performance in many respects.

Are ABEC Ratings the Only Factor in Bearing Performance?

Other Factors Influencing Bearing Speed

Apart from the ABEC ratings, bearing speed and performance are greatly affected by several other factors. Such factors are:

Lubrication: Bearing lubrication application is critical. If optimized, lubrication reduces the friction and the heat generated as the bearing rotates. Synthetic oils or grease are better options for performance than standard lubricants.

Load Capacity: Bearings need to tolerate the loads that will be placed on them, whether static or dynamic. Load bearings will best retain their speed and performance efficiency. Disputed parameters such as load ratings and contact angle are crucial in establishing whether a bearing suits the acting forces.

Alignment: Misalignment causes more friction and wear on the bearing contacts, which decreases speed. Correct and sufficient installation and alignment procedures will ensure optimum speed and extend the bearings’ working life by avoiding premature failure.

Surface Finish: The component of the bearing surface finish has an important effect on rolling contact friction. A smoother surface finish incurs less frictional drag and facilitates higher speeds.

External factors include temperature, humidity, and contamination, which can result in a high bearing speed. It should be noted that the broad range of slotted and shielded bearings is also a good option for allowing performance in adverse environments.

A technical approach to the problem, considering also ABEC ratings, allows one to outline what factors dominate bearin’.

The Role of Bearing Manufacturers in Quality

In seeking to provide more insights on this role, I took the bearing manufacturers’ website that showed during the Google search results. The first three websites contained the bearing manufacturers and suppliers from the top 3- first ranked pages. These manufacturers are precision engineers guided by strict standards such as those of the ISO and ABEC ratings essential to upholding product quality. From these sources, however, it can be seen that manufacturers instead focus on:

Materials and their Suitable Applications: Materials such as chrome steel or ceramic provide durability and the required performance characteristics under service conditions.

Manufacturing Methods: Utilizing CNC machining and heat treatment in bearing manufacturing processes increases their accuracy and operational life. Such processes are key in reducing defects and variability and enhancing reliability.

Testing and Validation Controls: All measures of parameters such as vibration frequency and noise level are implemented as stringent quality control measures. These validation steps ensure that only the performing and durable bearings enter the market.

Development: Enhanced research and development bring forth new developments, such as hybrid bearings with advanced properties. This focus enables the manufacturers to remain competitive, as the industry has a growing demand for high-quality bearings.

In this way, bearing manufacturers have put themselves in a position to provide products that not only meet the users’ requirements but often exceed them with improved reliability and performance.

Exploring Types of Bearings Beyond ABEC Ratings

When discussing types of bearings, when I went seeking information about other bearings besides the ABEC rating bearings, I restricted myself to information on three of the top Google websites. Well, this is what I found out:

Deep Groove Ball Bearings: Keep these characteristics in mind: They feature an extraordinary design that combines versatility, enabling them to bear radial and axial loads that are not excessive. They usually operate in washing machines and cars due to their quiet noise and vibration.

Angular Contact Bearings: Depending on how fast they need to be run, their primary use includes aerospace applications, spaceships, and robots. They have a pinched shape and bear even more axial load than deep groove bearings. Some essential technical parameters are the cavity’s contact angle and axial displacement capacity, which will likely change depending on operating requirements.

Tapered Roller Bearings are great for locations where there is high axial load capacity alongside radial load dispersion. They are generally employed for heavy machinery and automotive gear systems, where the elements of taper angle and roller length ensure performance targets are achieved.

Cylindrical Roller Bearings are best for heavy equipment with high radial loads. Their design provides speed allowance, where roller diameter and number are primary parameters impacting their performance.

These understandings explain why each bearing’s physical composition and specified engineering characteristics relate well to the required technology in the industry, stressing the point that more attention should be placed towards the selection rather than just ABEC Ratings.”

Is an ABEC 9 Bearing Always Better for Skates?

High-Speed Performance vs. Durability

When determining whether or not an ABEC 9 bearing is the best option for use in skates, one must consider speed and wear and tear, which are usually opposites. During my research through reputable sites, the general opinion regarding using ABEC 9 bearings on skates is based on what abilities and aims can be considered. The ABEC bears specific characteristics, including manufacturing accuracy and potential maximum speed. While some ABEC 9 bearings may provide better high-speed performance because they are more precise, they are not always required for skating unless competitive speed skating or inline speed racing is what you’re doing.

Another point is, however, the life span. Generally, most feel that the higher ABEC number (9) arms with low resistance and tight tolerances have high wear for deploying at high speeds. However, as the sites portray, a lower ABEC fitted bearing for ordinary or aggressive street skating is allegedly more economically viable, proving less wear and tear over time.

The following parameters taken from the websites can be used to support these arguments:

Precision and Tolerance: One of the most vital features of an ABEC 9 is the greater tolerance, which should help achieve more incredible speeds at less cost, although it will not last as long under continuous pressure.

Load Capacity: Skates can apparently withstand great loads, but the original intention of high ABEC bearings was not to distribute heavy shocks.

Material Quality: For bearings that attract higher ratings, the selection of the material may help increase their life span and maintenance.

To sum up, although using ABEC 9 bearings improves performance at high speed, specific skating applications require durability costs that should be considered.

When to Use Lower ABEC Ratings

From the information I gathered, lower ABEC ratings are better suited for those who do casual skating. Based on three websites I researched, these bearings are not intended for serious use, such as ABEC 3 or 5. The rationale behind this is the following:

First of all, spinning speeds and a harsh environment often affect the bearings, lowering their endurance.

General Usage: Bearings with lower ABEC ratings tend to be cheaper, but their price is worth it when it comes to the accuracy required for non-competition skating.

Care: Low ABEC bearings are less demanding than higher-end professional skater bearings. Because of this, they hardly seem to need any drastic maintenance.

As a result, this rating easily withstood conditions even under extreme loads, which is common for aggressive lower ABEC skaters. The added advantage is that it limits wear and tear on the bearings used in this case.

ABEC 9 Bearings: Best Use Cases

Through the exploration of the first three websites found on google.com, it was established that there are optimum use cases for the ABEC 9 bearings. High-precision bearings are found to be the best fit for professionals involved in skateboarding or for competitive races that require minimum friction and rapid high speeds. The sites provide the following features which necessitate the use of these bearings:

High-precision bearing: The bearing ABEC 9 has very tight tolerances, resulting in smoother and faster wheel rotation, which is crucial in competitions.

Reduced Friction: Because ABEC 9 bearings are built differently, friction is significantly reduced, allowing incredible speed and efficiency on smooth surfaces.

Performance Optimization: These bearings work best in controlled environments like indoor skate parks and racing tracks where their speed can be optimized.

Conclusively, the ABEC 9 bearings have a very low tolerance for error, making them suitable in circumstances where high speed and precise control are desired. They are also best suited for competitive speed skating activities.

Frequently Asked Questions (FAQs)

Q: What is the meaning of the ABEC rating for bearings?

A: The American Bearing Manufacturers Association defines the ABEC rating for bearings as the level of precision and tolerance. This system assists users in gauging the accuracy of all bearings, including ball bearings, and is called the ABEC rating system.

Q: Can I base my selection of bearings on the ABEC rating?

A: Yes, you can and you should, as this is the level of precision of the bearings. The ABEC 7 and ABEC 9 bearings can withstand tighter tolerances and should be used in applications that need high speeds, whereas ABEC 1 and 3 would be satisfactory in less demanding applications.

Q: How do ABEC 3 bearings compare with ABEC 7 ones?

A: What differentiates them is their tolerance level. In the case of bearings, higher tolerances mean more precision and less noise and movement in operation, which is a significant requirement for high-speed applications – ABEC 7 bearings fit this bill and have those tolerances. On the opposite end resides ABEC 3 bearings, which are less precise but suitable for general use.

Q: Do all bearings have an ABEC rating?

A: During many evaluations, especially with skate bearings, the level of the ABEC rating is widely acknowledged as the standard for classification of accuracy. However, this cannot be said for all types of bearings. Some specifically designed bearings are not rated under the ABEC standards, but they can still be quite performant and precise.

Q: Are ABEC 5 bearings worth having for my skateboard?

A: Indeed, having ABEC 5 bearings will add to the performance of your skateboard. This is because they manage to combine speed and accuracy perfectly. They are right in the middle of the pack, which is better than using ABEC 1 bearings. But they are not as expensive as ABEC 7 or 9 bearings.

Q: How precisely should a ball bearing work in terms of tolerances?

A: The feel or play tolerances of a ball-bearing component that usually falls under the rating by scale ABEC will determine its precision and performance. Less play enhances performance and enables efficient and even smoother motion for high-speed or precision-oriented applications.

Q: Is it true that a higher ABEC rating always means better performance?

A: This is not necessarily true. In as much as a higher ABEC rating means significantly higher tolerances, not all practices can benefit from such tolerances automatically. Other elements like the material used, lubrication, and design can be contributory, too. One should choose a bearing under the requirements of the application in question.

Q: Are all bearings categorized with an ABEC rating?

A: An ABEC rating is not applied to all bearings. Certain types of bearings, especially those meant for use in unique or non-standard environments, may not be rated within the ABEC framework. It is essential to consider the requirements and seek manufacturer clarifications as appropriate.

Q: Skate bearing: how does the ABEC rating affect the performance?

A: Skate bearing performance is rated in terms of the degrees of smoothness and speed when riding. Bearings with higher ABEC ratings, such as ABEC 7, which allow for a smoother, more efficient ride while going at higher speeds, are more popular with skaters who desire performance.

Q: What does it mean when the bearing is rated as ABEC 1 bearing?

A: When a bearing is categorized as an ABEC 1 bearing, it simply means that it has the lowest precision among the rated ABEC bearings. High speed and precision are important in some applications, but these qualities do not matter in others, and ABEC 1 bearings are perfectly acceptable.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8