Unlock the Secret: How Ball Bearings Magically Reduce Friction

Ball bearings are fundamental components in countless mechanical systems, yet their ingenious simplicity often goes unnoticed by the general public. These small but powerful devices are designed to minimize friction between rotating or moving parts, drastically enhancing efficiency, reducing wear and tear, and ensuring the longevity of machinery. This article will explore the principles behind how ball bearings work, the role they play in reducing friction, and the engineering marvels that make them an indispensable part of modern technology.

How much friction do ball bearings reduce?

Comparing rolling friction to sliding friction

It is important to highlight that rolling friction is much smaller than other forms of friction, such as sliding friction. This slight magnitude of rolling friction compared to sliding friction is primarily the reason ball bearings are so effective. Usually, sliding friction is defined as two surfaces moving tangentially concerning each other, and it is determined by the coefficient of sliding friction (µ_s) and the normal force. With very few exceptions, the coefficient of sliding friction between two metals is between 0.3 and 0.6 depending on the roughness of the two surfaces and the lubrication used.

On the other end, rolling friction is generated by the rolling motion of the spherical or cylindrical component over a surface. In most cases, it has a much larger coefficient, roughly between 0.001 and 0.005 for ball bearings with sufficient lubrication. Because in rolling friction, the contact area is very small (in ideal cases, point or line contact), this is. With a lower contact area, less energy is wasted as heat and deformation.

Widen the comparison to a steel bearing at 100N of load. At a load of 100N, a steel bearing exhibits a sliding friction of around 40N from a 0.4 sliding coefficient. In contrast, a ball bearing with a 0.002 rolling friction at the same load displays a frictional force of merely 0.2N. The difference in frictional force is astounding, setting both mechanisms apart. The reduction in energy expenditure, coupled with the massive reduction in wear and tear, is indicative of bulk bearing efficiency, further substantiating bulk bearings as the bearer of mechanical efficiency.

Employing more robust materials, a more advanced method of machining, and the right lubricant enhances the reliability of the performance by lowering rolling friction coefficients and optimizing component durability. These factors expound on the usage of ball bearings in consumer and industrial machines.

Factors affecting ball bearings’ efficiency in reducing friction

There are specific considerations that determine how efficient ball bearings are in reducing friction:

- Material Properties: The load-bearing materials need to be sufficiently hard and stiff and ideally, smooth. All-purpose materials like high-carbon chromium steel are used because they do not yield or wear, and do perform well.

- Lubrication: Elements such as viscosity, temperature range, and bearing material compatibility are critical to address. Effective lubrication minimizes the contact friction and even restrains overheating. For instance, low-viscosity synthetic lubricants have gained more traction in high-speed applications since they are more effective at reducing heat buildup.

- Bearing Design and Load Distribution: Optimum contact angles, for example, 15-25 degrees in angular contact bearings, are designed to handle axial and radial loads efficiently. Their internal structure, for example, the curvature of the raceways, has a direct influence on the load distribution and rolling efficiency.

- Precision in Manufacturing: Adherence to tolerances and the level of quality during manufacturing guarantee the right alignment and limit micro-defects that can result in rolling resistance. To classify precision levels, standards like ISO 492 or ABEC rating systems are used, with higher grades offering better performance (ABEC-5 or ABEC-7).

- Operating Environment: Performance can be affected to a great extent by external factors such as temperature, contaminants, and moisture. To keep particles from getting through, seals and shields are commonly added, and stainless steel is used in particular settings to resist corrosion.

By addressing each of these factors with tailored technical requirements, it is possible to enhance the effectiveness of ball bearings and ensure maximum efficiency in reducing friction in specific applications.

What are the key benefits of using ball bearings in machinery?

Improved efficiency and reduced energy consumption

Ball bearings play a critical role in machines as they provide relative movement between different parts. They also diminish the frictional force that impedes movement. This enables the components to function in a better manner and with more efficiency. Less energy is used because the frictional force which is required to sustain the motion is reduced. There is a decrease in the force required to maintain movement, and this translates to less energy being consumed.

- Cumulative Measures of Friction: Standard ball bearings possess a coefficient of friction of between 0.001 to 0.005, in contrast to the 0.1 or above estimated for friction between surfaces on plain bearings. This allowance is for enormous energy efficiency.

- Operational Temperature Range: Due to the sophisticated materials and lubricants used in ball bearings, performance between -30 °C to 150 °C is not a problem. This guarantees uninterrupted energy optimization in extreme conditions.

- Load Bearing Capacity and Speed Rating: The capacity to manage considerable radial and axial loads coupled with the ability to rotate at 30,000 RPM and above means that ball bearings are very easily energy efficient in speed-intensive applications.

By combining low friction, high durability, and optimized load handling, ball bearings contribute to overall energy-efficient machinery and extended operational lifespan.

Extended lifespan of moving parts and machinery

Ball bearings are considered essential for prolonging the life expectancy of moving parts and equipment as they help in reducing friction and word which in turn leads to an emergence of heat and mechanical depreciation.

- Friction Coefficient: This low coefficient ranges between 0.001 and 0.003 for ball bearings that have been well lubricated and in turn lower energy losses and surface wear.

- Material Hardness: Resistance to deformation, under great loads leads to the use of high-quality materials like chrome steel (Rockwell hardness of 60-65 HRC).

- Load Ratings: A single ball bearing can support containment stresses that exceed a hundred thousand N. The ratings of Ball Bearings without restrain usually exceed 100,000 N.

- Rotational Speed: Rated performance speeds between 10,000 Revolutions Per Minute to 30,000 Revolutions Per Minute allow for functionality in high-performance applications.

- Lubrication Requirements: These factors all affect the corrosion outcome as well as the life expectancy of the bearings. Special oils or greases relative to the working environment temperature range help in adequate lubrication, which in turn aids in corrosion protection.

Maintaining the system factors allows the ball bearings to fulfill their intended purpose and gives a chance to increase the working period of system components without losing quality.

Enhanced precision and smooth operation

- Dimensional Tolerances: The quality of the ball bearings relies heavily on the specified limit which decides the precision of manufacturing of a given component, be it ISO or ABEC standards. For instance, bearings that are ABEC-7 and above have several applications in highly precise spheres, for example; in aerospace or medical devices.

- Surface Finish: Excellent surface quality of rolling elements and raceways such as microns of surface roughness, for example; Ra ≤ 0.3 µm, decreases friction to a minimum and increases the ease of smooth functions by lessening the resistance to contact between parts.

- Material Quality: These are factors of high-grade steel or ceramic materials. These materials provide excellent strength and durability while greatly minimizing deformations that occur under load. For example, Ceramic bearings are especially favorable for operations at high speeds because of their lower weight and higher thermal expansion.

- Preload Settings: Correct preload diminishes the axial or radial play facilitating smooth rotation. Rotational Preload should be calculated depending on the load conditions of the application. Over preloading or over-applying stress will result in unwanted friction.

- Lubrication Type and Method: In certain operating conditions and environments such as -40 degrees to 150 degrees Celsius, the use of low-viscosity oils or specialized greases, facilitates useable operation at a range of different speeds and temperatures.

The optimized factors above lower the system vibration, improve the reliability of the system, and enable intricate motion control.

Are there any limitations or drawbacks to using ball bearings?

Maintenance requirements and lubrication needs

Ball bearings require periodic maintenance primarily due to their reliance on proper lubrication for optimal performance. The lubrication need tos depend on the operating conditions, including speed, temperature, and load. For instance:

- Operating way: In cases of high speed, the application of low-viscosity oils could be beneficial to counter friction and heat build-up, while moderate speeds may tolerate heavy greases that can be used for longer durations in between maintenance sessions.

- Temperature Range: For temperatures between – 40 C and 150 c, the performance of synthetic and tough thermal greases is stable and degradation does not occur.

- Load Conditions: In situations where the system operates under large heavy loads, it is ideal to incorporate extreme pressure additives to prevent wear and extend the life of the bearings.

These maintenance intervals should be planned depending on the operating environment, and cleanliness along with being free of contaminants should easily be accomplished. The lubrication can be detrimental if not maintained which will lead to high friction and vibration in the system and pre-mature wear of the bearing.

Load capacity and speed limitations

- Load Capacity: A greatly determining factor for bearing capacity is the type of bearing as well as the material that has gone into its construction. For instance, when taking standard ball bearings as an example, a bearing with a normal dynamic load rating ranging from 10 kN to 350 kN is great for moderate radial and axial loads. Roller bearings with dynamic load ratings above 500 kN are recommended for higher-capacity systems. For the bearing to function effectively and for a long period, one must ensure that the load that is imposed on it does not exceed 80 percent of the rated capacity of the bearing.

- Speed Limitations: The speed limit of a bearing is primarily dictated by the DN-value which is the product of the diameter of the bore in millimeters and the RPM of the shaft. For ball bearings with higher precision, the DN-values are generally between 300,000 to 1,000,000 whereas for roller bearings applications, the limits are lower from around 150,000 up to 500,000 DN. The selection of proper lubrication and material combination can lower heat generation, which is a significant issue at higher speeds.

By carefully evaluating the load relevant to your application, I can assist in aligning these requirements with the appropriate bearing specifications to ensure reliable and efficient operation.

How do ball bearings compare to other types of bearings?

Ball bearings vs. roller bearings: Which is better?

The choice between ball bearings and roller bearings depends on the specific application requirements, as each type has distinct characteristics suited to different operational demands.

Ball Bearings:

- Speed Capabilities: With minimal friction caused by a smaller contact area at the ball-raceway interface, Ball bearings command lower speeds. They typically support DN values up to 1,000,000 for precision applications.

- Radial and Axial Load Capacity: Roller bearings tend to perform better than ball bearings under heavy loads. Thus, ball bearings manage only moderate radial and axial loads.

- Applications: These bearings are best suited for electric motors, fans, turbines, and similar machinery that operate at higher speeds with lower loads.

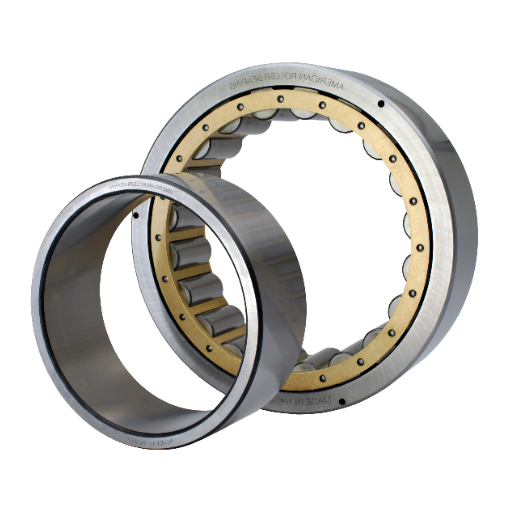

Roller Bearings:

- Load Capacity: The larger area of contact with roller bearings makes them better in managing stress than ball bearings. However, most designs limit their axial load capacity and thus, the radial load capacity remains heavy.

- Speed Limitations: As roller bearings command higher friction at their surface, they usually range between 150,000 – 500,000. Thus, lower speed capabilities are a synonym for roller bearings.

- Applications: Conveyor belts, gearboxes, and heavy machines are best operated at low speeds and thus are suitable for these bearings.

However, for sufficient performance in areas of high rotation speeds, the use of ball bearings proves beneficial. Roller bearings are more advantageous in situations such as heavy-duty work, where dependable performance and load-bearing are of utmost importance. Assessing the speed, lubrication, load, and other environmental factors, will ultimately lead to the most functional bearing choice.

Ceramic vs. metal ball bearings: Pros and cons

Similarly to ceramic ball bearings, metal ball bearings are also popular but have different distinct advantages and disadvantages. A comparison between the two is necessary to ensure the correct choice is made for a given application based on load capacity, working conditions, and performance requirements.

1. Ceramic Ball Bearings

Pros:

- Centrifugal Forces: Because of their lower density, ceramic ball bearings possess reduced centrifugal forces that allow for higher rotational speeds.

- Thermal Deformations Resistance: They can endure extreme temperatures without significant deformation, making them ideal for applications involving extreme heat.

- Friction Resistance: These materials possess smoother surfaces and lower coefficients of friction, therefore exhibiting higher efficiency and less energy loss.

- Abrasion Resistance: Their exceptional hardiness provides them with greater resistance to wear and prolongs their service life under abrasive operating conditions.

- Corrosion Resistance: Ceramic materials do not corrode like metals do when exposed to harsh environments such as chemicals or saltwater.

Cons:

- Costs: The significant expense of ceramic ball bearings compared to their medal counterpart can be attributed to process and material costs.

- Brittleness: Ceramics are inherently more brittle than metals, making them more susceptible to cracking under heavy shock loads.

2 .Metal Ball Bearings

Pros:

Metal possesses a higher degree of ductility compared to other materials making them more durable under impact loads as they can absorb shocks and resist fracture under heavy loads.

- Wider Load Capacities: Metal ball bearings can work with both radial and axial loads and are widely used for a diverse range of applications.

- Cost-Effective: Metal ball bearings are economically better compared to ceramics; they have lower costs of production and are easily adaptable for standard uses in industries and automobiles.

- Readily Available: The existing supply chain infrastructure for metal bearings manufacture allows for easy supply and short lead times.

Cons

- Higher Friction and Heat Generation: The use of metal bearings is associated with greater friction at higher speeds due to increased rotational friction which leads to increased playing surface temperatures and wear.

- Lower Speed Thresholds: heavier metals create larger centripetal forces that can limit high performance, which increases the need for lower running speeds.

- Limited Corrosion Resistance: Metal ball bearings will rust in corrosive environments unless they are protected by coatings of some type.

Ceramic ball bearings have their best applications in environments with a need for high-speed performance, thermal stability, and low maintenance such as aerospace or precision instruments. Metal ball bearings are advantageous in heavy-duty applications while being cost-sensitive, such as automotive or industrial machinery with a high-impact or changing load. It is very important to analyze all operations that including speed, load, temperature, and exposure conditions to choose the best value solution.

In which industries and applications are ball bearings most commonly used?

Automotive and transportation applications

Ball bearings are essential parts in many types of automotive and transport systems because they can reduce friction and serve as a support to both radial and axial loads. They are used in motors, turbines, transmission systems, wheel bearing hubs, driveshafts, and even in the suspension system. These applications of bearings in automobiles and other types of machinery require such bearings that can bear dynamic load changes, high speeds, and moderate amounts of environmental wear.

- Load Capacity: In automotive applications, the bearings are subject to load cutoffs which are broad ranging from super light to super heavy in e.g. electric vehicle motors commercial trucks, and even construction vehicles. The proper selection rests on the loading requirement rating of dynamic or static in Newton (N).

- Speed Ratings: In high-performance vehicles or electric, the bearings must withstand broad limits of speed ranging from 10,000-20,000 revolutions per minute (RPM).

- Thermal Stability: Ambient operating temperature for bearings in engines or transmissions should be comfortable from -40 degrees centigrade to +150 degrees centigrade but for some applications, even higher warm ambient tolerance is necessary.

- Environmental Resistance: Automotive bearings are bound to be exposed to broadening contaminants ranging from dirt, water, and corrosive road salts. Seals are used to aid in performance improvement as well as utilizing materials like stainless steel or ceramic.

- Longevity and Maintenance: For use in transportation systems, these bearings are designed for minimum maintenance intervals meaning usage with longer times with effectiveness and reliability, thus achieving less downtime.

These technical specifications are essential to the ball bearings’ reliable, efficient, and safe operation in a passenger as well as in a commercial transport system.

Industrial machinery and manufacturing equipment

Ball bearings play a critical role in industrial machinery and manufacturing equipment because they can endure difficult working conditions while ensuring reliable operation. The requirements that these bearings need to perform well in industrial applications are:

- Load Capacity: The bearing must have the ability to withstand both radial and axial loads above a certain threshold without any deformation. For example, depending on the size and application, hefty bearings tend to operate at over 50,000 N of burden.

- Rotational Speed: These bearings are often used in bearing housing for manufacturing equipment, for example, CNC machines or high-speed turbines. First and foremost, they ought to satisfy the precision limit of the apparatus and operational speed which is greater than 30,000 RPM. In such circumstances, ceramic hybrid bearings are often implemented.

- Temperature Range: In industrial infrastructure where heavy-duty workloads are non-stop, bearings require dependable performance in a temperature spectrum of -20° to 200°C or higher. Heat tolerant materials along with modern lubricants render such attributes.

- Vibration Resistance: Excessive vibrations are a common reality in industrial machinery, which leans towards the strength of designs that minimize wear and loss of operational efficiency.

- Custom Sealing Solutions: To avoid contamination from metal dust, lubricants, or other particulates, this type of bearing often uses seals or shields manufactured for specific applications.

When bearings meet these specific considerations, efficiency in industrial machinery improves, downtime is reduced and the service life is extended ensuring uninterrupted manufacturing operations.

Frequently Asked Questions (FAQs)

Q: How do ball bearings reduce friction?

A: Ball bearings reduce friction by using small, smooth balls between two surfaces to create a rolling motion instead of sliding. The balls act as a buffer, allowing the surfaces to move smoothly against each other with much less friction than if they were in direct contact. This design minimizes the point of contact between moving parts, resulting in a smoother rolling motion and reduced wear on components.

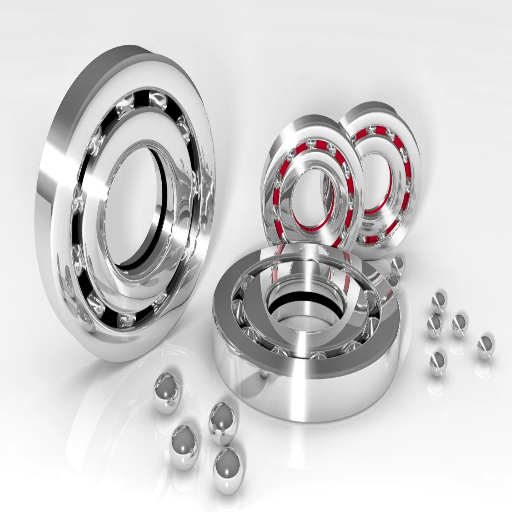

Q: What are the main components of a ball bearing?

A: A typical ball bearing consists of several key components: the inner ring, outer ring, balls, and cage (also known as a separator). The inner and outer rings, also called bearing races, are finely ground and polished to provide smooth surfaces for the balls to roll on. The balls are evenly distributed between these rings, while the cage keeps them properly spaced and prevents them from touching each other.

Q: Are ball bearings truly frictionless?

A: While ball bearings are designed to reduce friction significantly, they are not truly frictionless. There is still some friction present, albeit much less than in systems without bearings. The small amount of friction in ball bearings comes from factors such as the rolling resistance of the balls, any slight misalignments, and the viscosity of lubricants used. However, compared to other types of bearings or no bearings at all, ball bearings provide a near-frictionless experience in many applications.

Q: What are the different types of ball bearings?

A: There are several different types of ball bearings, each designed for specific applications. Some common types include: 1. Deep groove ball bearings: Used for radial and light thrust loads 2. Angular contact ball bearings: Designed for combined radial and axial loads 3. Thrust ball bearings: Specifically for axial loads 4. Self-aligning ball bearings: Can accommodate misalignment between shaft and housing 5. Ceramic ball bearings: Use ceramic balls for high-speed or high-temperature applications Choosing the right type of ball bearing depends on factors such as load direction, speed, and operating conditions.

Q: In what applications are ball bearings typically used?

A: Ball bearings are used in many aspects of our daily lives and industrial applications. Some common uses include: 1. Automotive industry: In wheels, transmissions, and engines 2. Household appliances: In washing machines, ceiling fans, and computer hard drives 3. Industrial machinery: In conveyor systems, pumps, and electric motors 4. Aerospace: In aircraft engines and control surfaces 5. Bicycles: In wheel hubs and pedals 6. Skateboards and roller skates: In wheels 7. Wind turbines: In the main shaft and generator These are just a few examples, as ball bearings are crucial in any application where reducing friction between moving parts is necessary.

Q: How do ball bearings contribute to energy efficiency?

A: Ball bearings contribute significantly to energy efficiency by reducing friction between moving parts. Less friction means less energy is wasted as heat, allowing machines and devices to operate more efficiently. This reduction in friction also leads to lower torque requirements, meaning less power is needed to overcome resistance and keep things moving. As a result, ball bearings help conserve energy in various applications, from small electronics to large industrial machinery, contributing to overall improved energy efficiency and reduced operational costs.

Q: How are ball bearings manufactured to ensure precision?

A: Ball bearings are manufactured with high precision to ensure optimal performance. The process typically involves: 1. Forming the rings: Inner and outer rings are forged or machined from high-quality steel. 2. Heat treatment: Rings are heat-treated for hardness and durability. 3. Grinding and polishing: Rings are ground and polished to achieve a smooth surface finish. 4. Ball production: Balls are formed from steel or ceramic materials and polished to a high degree of smoothness. 5. Assembly: Balls are placed between the rings, and the cage is added to keep them evenly spaced. 6. Quality control: Bearings undergo rigorous testing for dimensions, smoothness, and performance. This meticulous process ensures that ball bearings meet the strict tolerances required for efficient operation and long service life.

Q: What are the signs that a ball bearing needs replacement?

A: Several signs indicate that a ball bearing may need replacement: 1. Unusual noise: Grinding, squealing, or clicking sounds during operation. 2. Excessive vibration: Noticeable shaking or vibration in the equipment. 3. Increased heat: Bearings feel unusually hot to the touch. 4. Reduced performance: Equipment running slower or requiring more power than usual. 5. Visible wear: Signs of damage, corrosion, or deformation upon inspection. 6. Loose or sloppy movement: Excessive play or movement in parts that should be stable. 7. Lubricant issues: Discolored, contaminated, or leaking lubricant. If any of these signs are observed, it’s important to have the bearings inspected and replaced if necessary to prevent further damage or equipment failure.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8