Unlocking the Power of Lubricating Oil: Your Ultimate Guide to Smooth Operations

Lubricating oil plays a critical role in ensuring the efficient and reliable operation of mechanical systems across various industries. From automotive engines to industrial machinery, the proper application and management of lubricating oil significantly reduce friction, prevent wear, and improve equipment longevity. This guide aims to serve as a comprehensive resource, covering the fundamental principles of lubricating oil and its types, properties, and applications. Additionally, it will explore the science behind lubrication and provide actionable insights into maintaining peak system performance. Whether you are a seasoned industry professional or simply seeking to enhance your understanding of lubrication, this article is designed to equip you with the knowledge and tools needed to achieve optimal results.

What are the main functions of lubricants in machinery?

How does lubricating oil reduce friction between moving parts?

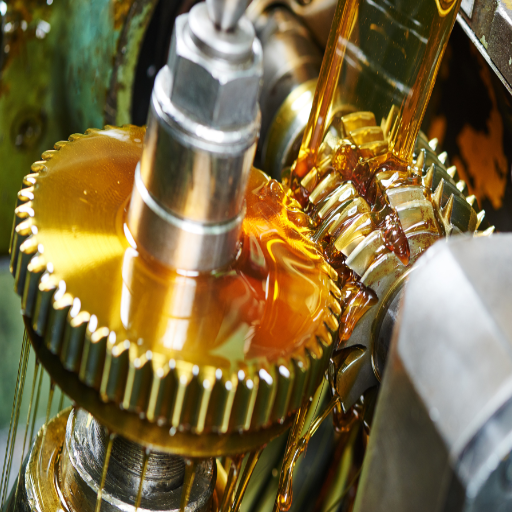

Due to the development of a protective film that shields against metal-to-metal contact, lubricating oil is capable of reducing friction between moving parts. This film minimizes surface interactions, and hence lowers the coefficient of friction. The viscosity of oil is crucial to forming and maintaining this film, with higher viscosity oils creating a thicker protective layer at lower speeds and higher load conditions.

- Viscosity: For easy movement and film strength as well, it determines how well the oil flows. For general machinery in normal operating temperatures, these values range from 30 cSt to 100 cSt.

- Viscosity Index (VI): An indication of the range in which an oil’s viscosity can exist without changing. With higher VI > 150 values, oils can be expected to perform in different thermal environments consistently.

- Additive Composition: These include anti-wear agents for example, Zinc dialkyldithiophosphate (ZDDP) and friction modifiers which improve lubrication at boundary mixed lubrication regimes and reduce wear.

- Oil Film Thickness: The surfaces are well separated, measured in microns, ensures sufficient thickness; bearable ideal thickness depends on operational load and surface roughness.

While these oils are needed for efficiency enhancement in machinery, they do come at the added cost of increased energy loss and wear even under demanding conditions.

Can lubricants prevent rust and corrosion in metal components?

Yes, lubricants can indeed inhibit rust and corrosion of metal parts, and I employ several mechanisms to achieve this, such as creating a barrier that minimizes the contact of metal surfaces with water, air, or other corrosive elements.

- Corrosive Preventive Additives: Additives like calcium sulfonates or zinc dialkyldithiophosphate, which neutralize corrosive substances and have protective layer,s are called rust preventive additives.

- Demulsibility: Effective lubricants have strong water separation capabilities, which are defined and quantified under ASTM D1401 standards, thus reducing water contact with the metal to a minimum.

- Film Strength: Lubricants possessing strong film-forming tendencies are physically capable of preventing contaminant ingress as tested in the Four Ball Weld Test and other tests of the kind.

- Filtration: High Total Base Number (TBN) indicates the capability of the organic lubricant to neutralize acids formed during the reaction or process, which ensures no corrosive damage will be inflicted over longer durations of use.

Ensuring the choice of lubricating oils along these lines assures protection against corrosion and rust for long periods in a variety of industries and operational conditions.

What role does viscosity play in lubricant performance?

Working viscosity is everything in a lubricant because it measures the resistance of the fluid to flow at different temperatures and during different workings. In my view, retaining precise viscosity ensures proper lubricating film formation with minimum wear and friction between components.

- Viscosity Index: A Higher VI implies that the lubricant will retain its viscosity better while being subjected to extreme temperatures, meaning it will not thin out while being hot or thicken in cold conditions.

- Kinematic Viscosity: This is measured at set temperatures of 40 degrees centigrade and 100 degrees centigrade. If gives insight into how the lubricant will behave during day to day operations.

- Shear Stability: This defines how well the lubricant will retain its viscosity after being put under mechanical power and the lubricant will be under strain over a long period of time.

Choosing the lubricant with the right working viscosity and the matching operational demands guarantees the right protection, which in turn helps in optimizing efficiency.

How do you choose the right lubricant for your equipment?

What’s the difference between mineral and synthetic oils?

Mineral oils come from crude oil’s refinement, while synthetic oils are formulated for advanced performance. Though cost-efficient, mineral oils only operate reliably from -20°C to +100°C, and have low thermal stability. In contrast, synthetic oils work from -40°C to +150°C and sometimes exceed that limit depending on the formulation, thanks to their oxidation resistance, and broad operating range.

- Thermal Stability: Synthetic oils create less sludge build-up due to slower breakdown at higher temperatures.

- Viscosity Index (VI): The higher VI found in synthetic oils results in consistent performance due to lesser change in viscosity across a range of temperatures.

- Oxidation Resistance: The superior oxidation resistance found in synthetic oils means lesser degradation over time, allowing for longer engine service life.

- Pour Point: Extreme cold performance is better with synthetic oils because of lower pour point, e.g. below -40°C.

Cost-effectiveness makes mineral oils favored for standard applications, but for extreme conditions with maximum efficiency and equipment lifespan required, synthetic oils are better.

How do additives enhance lubricant properties?

Uses of additives in lubricants are very important, especially in coping with particular mechanical and environmental problems that could limit performance and durability.

- Improvement in Viscosity Index: Additives like viscosity index improvers are used to change the flow characteristics of the lubricant to ensure it is suspended when the temperatures are low and would not become too thick and flow at high temperatures.

- Resistance to Oxidation: Adding to the life of lubricants, antioxidants retard oil’s oxidative break down and extend its life. This is especially true at the higher operating temperature range where reactions in cycling oil could prove to be a problem.

- Preventive Action Against Wear: ZDDP’s (zinc dialkyldithiophosphates) work as antiwear additives, which means they provide almost complete protection against wear on some metals which leads to the formation of frictional pairs on the metal surface,s and at high loads/pressur,e these surfaces glide over each other with the lubricant fluid.

- Preventive Detergents and Dispersants: Sludge and deposits are unwanted contaminants that need to be controlled so that the functioning of equipment is not compromised or lost. These additives perform the function of dirt holding, so even after a long duration of operations the plant and equipment remain clean.

- Preventing Rust and Corrosion: Adding rust inhibitors enhances protection from moisture for metal parts, which tend to corrode and lose their value in high humidity or changing acid/alkaline media.

Lubricants, needing to withstand extremely high pressure, temperature, and long operation intervals, are offered additional protection with the performance lubricants meeting the primary requirements for machinery protection.

What are the most common types of lubricants used in the industry?

How does engine oil differ from transmission fluid?

The fluids serve different purposes; oil helps in cleaning the components, and Transmission fluid resurfaces the necessity of lubrication. Engine Oil is used to cool a car’s engine by lubricating its parts, which solitary cleans and ensures less impact is delivered when met with heat or motion. Oil shown has a viscosity between 5W-30 and 10w-40 on the Omega scale based on need and temperatures. Engine oil also contains a combination of cleaners, dispersants, and anti-wear ingredients to improve the outcome of the oil.

As for Transmission fluid; its unique for the transmission systems. It aides in cooling the components. Additionally, it also lubricates and provides the hydraulic pressure that fades with certain motion. Automatic transmissions commonly have high internal pressure diminishing the heat. Transmission oil is constructed to endure such conditions by having a set viscosity numerc along with heat resistant features.

Even when focusing on attaining improvement in controlling the temperature during the operation, these liquids require a change in composition towards the purpose of either oil or transmission fluid accordingly.

What are the advantages of using grease over liquid lubricants?

In particular operational situations, grease offers numerous benefits over liquid lubricants. The first one that comes to mind is grease having superior adhesion to surfaces, which helps retain lubricants in cases where leakages are more likely to happen. A good example is a vertical or open mechanism machine. This property reduces the chances of loss or drainage of lubricants, unlike liquid lubricants. Secondly, grease protects sealed areas from external influences like water, dirt, and other debris, which is handy in mechanically harsher environments. Moreover, grease lasts longer in several applications, and this helps in further applications and maintenance.

- Viscosity and Consistency: Grease is a mixture of thickener and lubricating oil, resulting in a semi-solid state grease having a yield strength, which helps it resist movement even in highly demanding conditions.

- Operating Temperature Range: The Performance of grease is suitable at several temperatures, however, some forms are optimized for ranges of high as well as low temperatures and so require use.

- Load-Carrying Capability: Grease having high viscosity can endure very high pressure and therefore, is suitable for heavy applications or low speed mechanisms.

- Water Resistance: Some formulations of grease are made with certain additives to increase their ability to function in damp and wet conditions.

These features make grease ideal for use with intermittent work, in hard-to-reach locations, or when better protection from the surrounding environment is required.

When should you use silicone-based lubricants?

Silicone oils are best applied in situations where sustained performance, high compatibility with materials, and tolerance of extreme temperatures are of utmost importance. These lubricants are effective throughout a broad range of temperatures from -40 to 40 °C, so these lubricants are perfect for regions where there is a high level of climatic variability. Furthermore, silicone oils possess excellent free radical, moisture, and chemical deterioration resistance, which allow them to be used in humid or chemically aggressive environments with ease.

- Thermal Stability: Performance under continuous operation in high-temperature conditions without breakup or loss of viscosity for a specific period.

- Material Compatibility: Use in large number of substrates, including plastics, rubbers, and metals, is permitted because of its non-active nature.

- Water Repellence: Stops moisture from entering so application can be used in wet or damp settings for long periods.

Silicone oils are best recommended for sealing O-rings, lubricating plastic parts, or shielding delicate machines from harsh environmental conditions. They are extensively used in the automotive, industrial, and consumer products due to their non-corrosive features.

How do you properly apply and maintain lubricated systems?

What’s the correct way to lubricate open systems?

When lubricating open systems, I ensure that the system is washed thoroughly to avoid any interference from dust, debris, or older lubricant remnants that can affect performance. Based on the system’s operating conditions, such as exposure to load, speed, temperature, and environment, I select the best lubricant type. For example, thick lubricants with high viscosity are best applied when the system is under heavy load and moving at a slow speed, while thin lubricants with low viscosity work best when the system is running at high speed.

- Operating Temperature Range: Ensure that the lubricant has not lost functionality. As an example, synthetic lubricants tend to remain functional from -40°F to over 500°F with some variations.

- Viscosity (cSt): The operational speed and load determines viscosity; i.e. 100-150 cSt under medium speed and heavy load.

- Environmental Exposure: In cases where lubricants need to work in moist or corrosive environments, water resistant or anti-corrosive lubricants should be used.

To avoid contamination or wear, once exposed parts are lubricated, excess lubricant should be removed. To ensure consistent system performance, regular inspection and reapplication depending on the depletion rate of the lubricant is important.

How often should you change the oil in different types of machinery?

The time frame for changing oil depends on the machines and devices, their operating environment, and the oil itself.

- Industrial Equipment: For components that work nonstop, I change the oil after 4000-8000 operational hours with mineral oil. If the oil is synthetic and my equipment has a lower thermal stress, then I could go from 12000 to 16000 hours.

- Automotive Engines: For standard oil, the average recommendation is 5000-7500 miles; for synthetic oil, it is typically ten thousand.

- Hydraulic Systems: For premium multi-grade standard 1000-2000 hours change should suffice with standard hydraulic oils, featuring antiwear properties.

Unconditional factors must be evaluated as workload, temperature extremes, and contamination risks of oil change intervals. Within boundaries, regular oil analysis can sustain the equipment performance for much longer.

What are the signs that indicate it’s time to replace your lubricant?

Symptoms of replacement should be considered when the lubricant efficiency drops or when the lubricant visually changes.

- Changes in Oil Viscosity: Either above or below mean Viscosity values suggest contamination of the oil, thermal degrading, or other sources of dilution. Regular Viscosity measurements should confirm this basic range. Therefore, values below the minimum for the application of the lubricant suggest that replacement should be considered.

- Oxidation: Exposure to heat and oxygen can result in oxidation and, hence, the formation of sludge. Oxidized oil can always be tested through oil analysis. If the Total Acid Number (TAN) changes beyond the recommended limit, that is a warning signal.

- Contaminants: Lubrication can be compromised with dirt, water, or metal particles. Increased contamination levels can be found by particle counting or through spectrometric methods, which, if detected, should lead to oil changes.

- Additive Depletion: A lubricant with depleted antiwear agent or corrosion inhibitor cannot protect components and thus needs further testing. Test for the depleted concentration of additives to see if there are still some left for protection.

- Thermal Breakdown: High operating temperatures lead to thermal breakdown; thus, discoloration or a burning odor suggests the lubricant is excessively degrading.

- Noise or Performance Problems: If a certain component is noisier than normal or is not functioning at optimal efficiency, it may be the result of inadequate oil lubrication due to its degradation over time.

By constantly monitoring these values and analyzing the equipment’s behavior, I make certain that lubricants are changed in advance of when their replacement is actually required to avoid loss of efficiency or damage.

How do lubricants impact energy efficiency in mechanical systems?

Can the right lubricant improve fuel economy in vehicles?

Yes, the proper lubricant can save substantially on fuel costs. Sophisticated lubricants that reduce friction between machine elements can optimize energy transmission in the engine and drivetrain, reducing energy loss. For instance, low-viscosity synthetic oils can lower internal fluid friction at higher pressures without lowering lubrication effectiveness due to sufficient film strength.

- Viscosity Index (VI): A high VI guarantees stable viscosity from low to high temperatures. This permits reduced friction during cold starts as well as protection from high wear at elevated operational temperatures.

- Friction Coefficient: Lubricants with low Friction coefficients directly reduce resistance between surfaces, which will improve fuel economy.

- Additive Package Composition: Modifiers like friction and antiwear modifiers can further enable lower boundary lubrication, which increases energy expenditure.

- Oxidation Stability: A lubricant with high oxidation resistance will hold its properties for long periods which guarantees consistent efficiency and performance.

With these factors, I can select the proper lubricants that enhance vehicle performance, decrease energy consumption, and prolong the wear of vital parts.

How do lubricants contribute to energy savings in industrial machinery?

By using lubricants and other oils with desired physical attributes, I ensure that the moving parts in the machinery turn smoothly, thus ensuring minimum energy loss. Specifically crafted lubricants provide energy-efficient savings and improve the overall efficacy of the satellite’s components.

- Friction Coefficient: It further correlates with the efficiency of fuel consumption. A low-friction lubricant minimizes the operating energy needed to power components. In turn, postponing inviting mechanical load till the optimal component fuel consumption sufficiency is achieved, especially under high load condition.

- Viscosity Index (VI): Using lubricants which have high VI ensures that the optimal viscosity is maintained throughout the broad range of temperatures. Doing so guarantees that the machinery does not lose more energy especially during the start-up phases and while working on elevations of high temperatures.

- Additive Package Composition: Modifiers together with extreme pressure agents improve the performance of the additive and lessen the wear and tear over time that the lubricant experiences in challenging conditions, thus sustaining the energy effectiveness.

- Thermal Stability: Lubricants with extreme thermal stability do not degrade under high operating temperatures and thus retain efficiency, resulting in minimal downtimes for maintenance.

By carefully choosing lubricants with these characteristics, various benefits can be obtained, including maximizing energy efficiency and lowering costs while also assisting in sustainable machinery performance.

Frequently Asked Questions (FAQs)

Q: What is lubricating oil, and what are its main uses?

A: Lubricating oil is a substance used to reduce friction between moving parts in machinery. It is mainly used to lubricate various components such as bearings, pistons, and shafts in engines, compressors, and other mechanical systems. Lubricating oil is used to reduce wear, dissipate heat, and ensure smooth operation of machinery.

Q: What is the difference between lubricant and grease?

A: While both lubricant and grease serve similar purposes, the main difference lies in their consistency. Lubricating oil is a liquid that flows freely, while grease is a semi-solid substance. Grease is essentially oil mixed with thickeners, making it ideal for applications where oil might drip or run off. Lubricating oil is typically used in high-speed applications, while grease is preferred for slower-moving parts or where long-lasting lubrication is needed.

Q: How is lubricating oil produced?

A: Lubricating oil is primarily derived from crude oil through a refining process. The production typically involves vacuum distillation to separate different oil fractions. The base oil is then treated and blended with various additives to enhance its properties. Historically, the Vacuum Oil Company played an important role in developing lubricating oils. Today, synthetic lubricants are also produced using chemical processes, offering improved performance in certain applications.

Q: What are some common types of lubricating oils?

A: There are various types of lubricating oils, each designed for specific applications. Some commonly used types include motor oil for automotive engines, compressor oil for air compressors, hydraulic oil for fluid power applications, and gear oil for lubricating gearboxes. Specialized lubricants may also contain additives like PTFE or graphite for enhanced performance in specific conditions.

Q: How often should I change the lubricating oil in my equipment?

A: The frequency of oil changes depends on various factors, including the type of equipment, operating conditions, and the specific oil used. For common motor oil in passenger vehicles, changes are typically recommended every 3,000 to 7,500 miles or every 3 to 6 months. However, for industrial equipment or specialized applications, it’s best to consult the manufacturer’s guidelines or conduct an oil analysis to determine the optimal change interval.

Q: Can lubricating oil be recycled?

A: Yes, recycling lubricating oil is possible and highly encouraged for environmental reasons. Used oil can be collected, re-refined, and used to produce new lubricating oils or other petroleum products. Recycling helps conserve resources and prevent environmental contamination. Many service stations and recycling centers accept used oil for proper disposal and recycling.

Q: How do I properly apply lubricating oil to a shaft or bearing?

A: To properly lubricate a shaft or bearing, first ensure the area is clean and free of debris. Pour the oil or apply it using an appropriate applicator, ensuring even coverage. For bearings, it’s often best to apply the lubricant while the component is in motion to ensure proper distribution. Be careful not to over-lubricate, as this can lead to excessive heat generation and potential damage. Always follow the equipment manufacturer’s recommendations for the type and amount of lubricant to use.

Q: What are some signs that indicate I need to add or change lubricating oil?

A: Signs that you may need to add or change lubricating oil include increased noise or vibration from machinery, higher operating temperatures, decreased performance or efficiency, visible metal particles in the oil, or oil that appears dark and dirty. In diesel engines, excessive exhaust smoke can also indicate the need for an oil change. Regular oil level checks and following recommended maintenance schedules are crucial for optimal equipment performance.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8