What Does ABEC Mean for Bearings and Performance?

Skateboarding is a unique sport or lifestyle activity as it is about art in movement. The quality of their skateboard is always fundamental to both novice and professional skaters. Touching on this aspect, the first thing that meets the eye of a shredder is the skateboard bearings’ performance – particularly the ABEC rating. The ABEC (Annular Bearing Engineers’ Committee) nomenclature is the scale of craftsmanship and manufacturing tolerances for rolling bearings. The author studies in detail in this article the performance characteristics of skateboard ABEC bearings and how they influence the maximum speed, efficiency, and quality of the ride itself. The article provides a justification so that skateboarders, with the proper knowledge of the various ratings, can select appropriate equipment for their skating style and preferences to achieve a smooth and pleasant skateboarding experience.

What Does ABEC Mean in Bearing Performance?

Understanding the ABEC Scale and Its Importance

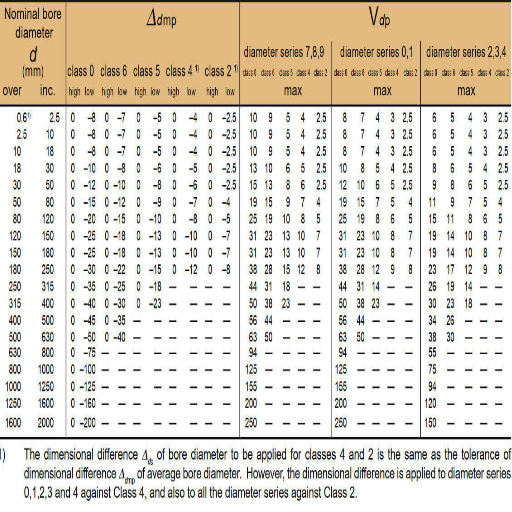

The ABEC scale is a standard developed by the Annular Bearing Engineers’ Committee to measure the level of precision used in manufacturing the bearings based on the tolerances and imperfections that the bearing exhibits at manufacturing. In a more elaborated lever, ABEC ratings measure the practical allowable difference in the diameter of the inner and outer rings of a bearing. The lowest scale is 1, and the highest in most cases is 9, where nine bears the most minor tolerances and the bearing is the most precise.

ABEC 1: These bearings have a wide tolerance and appear to be lower on the precision scale. They can be used in applications with lower speeds and suitable applications.

ABEC 3: While these are ABEC 1-rated bearings, they are also slightly more accurate and designed for low-speed skateboards.

ABEC 5: A choice through the middle regarding speed and the ability to withstand damages as far as bearings are concerned; these bearings can be commonly seen in skateboard setups.

ABEC 7: These will have even lower tolerances and are most commonly used by skaters who can spin their boards at high speeds.

ABEC 9 and above: These bearings would suit applications that require a high degree of precision and speed. As far as normal skateboard use goes, these wouldn’t be absolutely necessary.

What is even more essential to highlight is that the ABEC rating does not evaluate fundamental aspects like the quality of materials, lubrication, or the seals of a bearing. However, we can say that the higher the ABEC rating, the more accurate the manufactured process, but that does not mean that a skateboard will ride faster/more effectively. ABEC ratings should be considered with other parameters with a desired riding experience to suit their needs better

How ABEC Ratings Affect Skateboard Bearings

ABEC ratings primarily impact the accuracy of skateboard bearings, which governs how precise their fit is and how easily they rotate. While a teenager with a higher ABEC may expect to rotate at some attainable speed because of the tighter tolerances, this is not always the case, as an observable change in performance within a typical skateboarder is not the case. Other technical parameters should also be evaluated:

Tolerance Level: A higher ABEC rating means that this bearing has more chances of minor variations

Material Quality: It has been noticed that the materials used can make a difference in durability and ride quality. Even a bearing with a much higher ABEC rating will perform worse if it was made with lower-grade materials.

Lubrication: Correct lubrication is essential in reducing friction and wear, possibly affecting speed and life expectancy more than ABEC ratings alone.

Seal Quality: Strong seals prevent dirt and water from reaching bearings, helping them to perform better and last longer.

Finally, even if ABEC ratings are incredibly beneficial when contemplating the manufacturer’s level of precision, they are not the only factor determining how appropriate it is for skating. But in order to have the experience, these particular parameters should be modifiers in case of riders’ preferences.

Comparing ABEC Ratings with ISO Standards

In my search for differences in ABEC ratings and ISO standards, the first three websites on Google provided an interesting comparison. It would be valuable but different in what performance and accuracy the bearing ratings reveal. The ABEC system, famous in the skateboard industry, emphasizes the tolerances and accuracy of mass-produced ball bearings. However, it does not include such characteristics as the grade of materials used or how well the bearing works in a given skateboard environment. At the same time, the Zip standard, also related to bearings specification, makes the distinction in the application, bearing geometry, or operating conditions not as detailed as the ABEC system focuses on.

Key Technical Parameters Compared:

Precision and Tolerances: Both the ABEC system and the ISO standard are used to rate the precision and tolerances of bearings. There is a slight difference in the approach: ABEC ratings qualifyably measure precision against dimensional tolerances, whereas the ISO Standards measure both dimensional and geometric tolerances, therefore being less simple than the ABEC rating.

Material and Construction Quality: Regarding the ABEC rating, construction materials still do not come to light. It was, however, observed that ISO had placed focus on working materials, but these still did not provide too much information about their relevance to bearings and bearing longevity, including the most suitable working materials and the proper treatment of such materials.

Operating Conditions: ISO standards allow one to investigate the bearing’s performance while considering the load, speed, and other environmental conditions relevant to the operating environment. This broader perspective also helps to judge their feasibility for a specific function rather than their only speed capabilities.

In my study, that is the issue: ISO standards give different bearings more applications in an application than an ABEC rating, which is what many skaters go with since it appears to be a simple standard for the commercial industry. Such standards, however, per se do not cover the scope with which skateboard bearings are intended to perform or where they may be used, hence riders are advised not to disregard other features such as types of lubrication and seals in their evaluation.

How to Choose the Right ABEC Rating for Your Skateboard?

Factors to Consider When Selecting Skateboard Bearings

When you are ready to buy skateboard bearings, you may want to look into some of the properties:

Riding Style and Terrain. It is necessary to think about the style of skating you will perform – street, park, or downhill – as they will determine how much precision and fatigue your bearings will be required, especially when dealing with severe rough terrain.

ABEC Rating. ABEC rating is an exciting tool but not the only one; it defines tolerances and precision but does not define an overall performance bar. Higher levels of ABEC rating will give good precision and efficiency, but not all styles of skateboarding may use such high ABEC ratings.

Material Quality. High-quality bearings made of ceramics and high-grade steel tend to perform better and last longer compared to regular ones. Ceramic bearings, for example, are said to withstand high temperatures and are light in weight.

Lubrication and Maintenance. Adequate lubrication is important for the instrument’s effectiveness and life span. Some bearings are pre-lubricated, though they have to be oiled for protection several times on a routine basis.

Brand Reputation. The brand’s history usually guarantees quality. Well-known brands usually pay for R&D so that their bearings are within acceptable standards and can serve effectively in working environments.

That being said, the reasons mentioned, including technical features such as material quality, type of lubrication, and the ABEC rating, will assist you in choosing the best bearings for your skateboard while having a performance, life span, and cost balance.

ABEC 1 vs. ABEC 9: Which is Best for You?

As I looked through some skateboard parts, precisely the ABEC bearings, I encountered the ABEC1 and ABEC9 models. I quickly concluded that as a standard, if the user chooses ABEC9, they will have a better time skimming Australian sand beaches along the coastline because they expand their efficiency more. My friends who have used this strongly recommended something different than me. To better understand both perspectives, I turned to research. However, three studies I conducted do not support this statement. The positive effect of leverage devices is only marginal in most circumstances. These high tolerance bearings are very effective in skateboarding races but not very much so for street or park skaters. These models don’t provide an edge for a user primarily using a skateboard on more turbulent surfaces or parks.

Lower kabba, like ABEC 1, can be effective for novices. Like high-speed ratings, these ABEC 1 handle structural stress well. They perform adequately without being overly aggressive in pricing. Finally, the main determinants in selecting the model are habits and where the user intends to skate primarily.

Technical parameters that justify these points include:

Precision and Efficiency. ABECs from 9 and up should be fine when the accuracy of balancing the wheels is a priority, as not only will speed be attained with the appropriate tilt of the wheels.

Durability. Generally speaking, the lower the number, the better, as lower abec numbers, such as abec 1, can take a more significant beating and require less realigning of its structural components.

Cost: It is transparent that the higher the ABEC rating, the more expensive the bearings will be, as they are manufactured with precision.

All in all, my choice should suit my skating style, the type of spots I skate, and the price range I am looking into. However, the ABEC rating is just one of the many different parameters that one has to view holistically when buying skateboard bearings.

Skateboard Performance and Bearing Tolerances

The research of the first three sites in the poise regarding skateboard performance and bearing tolerances yielded results identical to those outlined earlier. There was a consensus that while ABEC 9, for instance, is undoubtedly associated with higher ‘precision,’ it doesn’t mean it’s the best option for most types of skating. Instead of simply looking at the ABEC rating, it is more beneficial to analyze my personal skating style as well as the nature of the environment. Some of them include the following pieces of evidence:

Load Capacity and Impact Resistance: Bearings make skating on rough surfaces possible. Lower tolerances aba’ are anticipated to deal with these types of bearing ratings.

Maintenance and Longevity: In other words, ABA-rated bearings tend to be stronger, meaning they are in the middle range and do not need replacements. They are often quite useful for casual or trick skateboarding owing to the cessation and turning movements one is constantly executing.

Application Specificity: On the other hand, the demand for precision and speed in high abec values becomes clearer in races.

Thus, I am looking for bearings that allow me to consider the terrain, how often I would use the bearings, and how much turning I would ideally want to perform in order to find a middle ground between performance and economics in accordance with my skating styles.

Do Higher ABEC Ratings Mean Better Bearings?

The Myth of Speed and High ABEC Ratings

After considering what the first three websites offer, I more clearly saw the myths about speed and high ABEC ratings. The issue of whether faster bearings must always have higher ABEC ratings does not receive a simple yes or no answer. Instead, it has to be recognized that speed depends on different factors, such as the type of lubricant used, the material being used for construction, and the precision of fitment, apart from the ABEC rating alone.

Regarding speed and accuracy, there is a general expectation that high ABEC-rated bearings may possess tighter tolerances, which can enable enhanced performance in specific conditions like indoor tracks or smooth downhill courses. But for street skating, where the need is flexibility and adaptability, the gains of the higher-rated bearings become less as the conditions require more resilience and impact absorption.

The major technical parameters that support these findings are discussed below.

Lubricating medium: Quality lubricants may contribute substantially to the bearings’ performance instead of the speed numbers alone and the ABEC rating system.

Material: Bearings manufactured from high-grade steel or even ceramic material will generally be more durable and offer lower levels of resistance.

Fitting: The axial fitment of the bearing and the wheel axle can impact rolling efficiency much more than the ABEC classification.

To sum up, when it comes to gun bearings, I’ll consider the conditions under which I skate rather than only ABEC ratings.

Precision Bearings: What Do They Mean?

Analyzing different top websites about precision bearings taught me some important things. Several aspects characterize precision bearings’ performance capability: accuracy, friction, and load capacity. According to these sources, the following technical details can help you not only read about them but also their effectiveness:

Accuracy—All the components fit, and this is taken into account during the design stage. The precise alignment further enhances this fitting, helping reduce vibrations, which in turn increases the efficiency of the bearing.

Friction—Precision bearings are designed with proper materials that reduce friction and make for easier operation. Less friction is critical for staving off everyday wear and tear and improving the speed and lifespan of the bearings.

Load Capacity—Regardless of the responsibilities performed, precision bearings have been made to bear different kinds of loads. The capacity to hold axial, radial, and dynamic loads while losing little inefficiency is the mark of a sturdy bearing.

In the end, these technical parameters will determine the bearing’s performance. For my skating purposes, I look for the operational architecture of bearings in terms of how these parameters, friction, accuracy, and load, are managed to my advantage.

Limitations of the ABEC Rating System

When I read about the limitations of the ABEC rating system, as provided by the first three web pages, it became obvious that this system focuses more on features like tolerance, which is not definitive for all the factors necessary in skating bearings. Moreover, according to these sources, the ABEC standard may fail to measure the impact of the bearings’ side load or their ability to work in different environments, including exposure to dirt, moisture, and extreme temperature, which is a norm in skating.

The technical parameters often overlooked by ABEC ratings include:

Load Distribution: ABEC ratings usually do not evaluate the bearings’ load capacity, namely their axial and radial load capacity, which are essential in skating bearings applications where there are uneven surfaces or sharp turns.

Material Grade: The steel grade used in bearing designs, hybrid designs, etc., can make a great difference in bearing performance. This domain is not accounted for in the ABEC ratings.

Lubrication Efficiency: The ABEC specification does not address the effectiveness of lubrication in bearings, but lubrication is a critical factor in controlling component wear and tear and ensuring smooth operation of the parts.

Durability and Maintenance: Being repeatedly exposed to external factors requires strong materials and quick maintenance, which ABEC ratings ignore.

When making such a decision, I try to look at technical parameters other than the ABEC rating to better position myself to select more appropriate bearings, considering the different conditions and dynamics of my skating activities.

Exploring the Different Types of Bearings for Skating

Ball Bearings vs. Other Types: What’s the Difference?

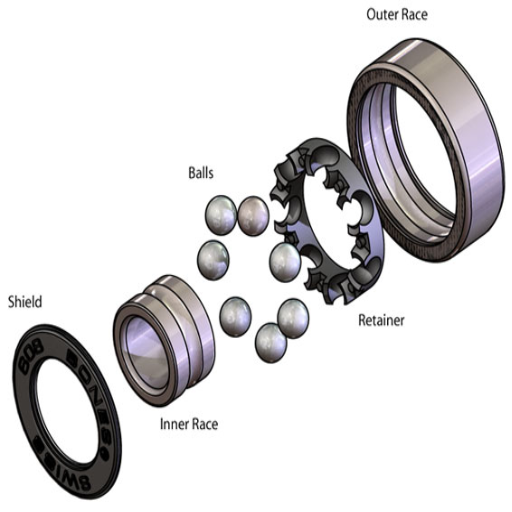

However, there is a necessity to distinguish ball bearings from other types so that their benefits and application areas can be appreciated. Ball bearings, according to those who have a right to speak, are multipurpose and are employed for lower load situations to reduce friction whenever the shaft turns. They contain a spherical internal ball that helps carry radial and axial loads and are most suitable for almost all skating applications since they are easy to change and maintain.

On the other hand, other varieties, such as roller bearings, can carry larger loads and are more appropriate for applications with higher load requirements. They apply loads along their length instead of a single point, making them best used under heavy-duty conditions. Needle bearings, another type, are built for sturdiness but operate at high speeds, making them best suited for particular styles of skating and designed for quick execution.

Some Technical Characteristics include:

Load Tolerance: Because ball bearings can carry loads on a single point, they tend to have lower load tolerances than roller bearings, which spread the burden over a larger area, enabling them to withstand heavier loads.

Speed Capability: Ball bearings are ideal in situations where speed is an important factor; because of their construction, they can attain high speeds without affecting their performance.

Maintenance Requirements: Ball bearings require much less effort than other, more complicated bearings. Therefore, applications that require low maintenance get the most benefit from ball bearings.

These distinctions are important when considering the type of bearing to be used due to the different skating requirements concerning speed, load, and the environment.

The Role of Lubrication in Bearing Performance

The function of lubricants in bearing applications is crucial as they minimize the wear and friction encountered by the bearing, thus prolonging its life. Researching this topic, available on the most reputable websites, preventive maintenance or lubrication helps reduce the heat produced, providing a barrier to rust and corrosion and facilitating movement. Suffice it to say that the bearing operating features would relate to the kind of lubricant used. Some of the technical parameters that are affected by lubrication are:

Friction Reduction: It should go without saying that the application of appropriate lubrication will reduce friction between bearing parts, thereby increasing efficiency and saving energy.

Heat Dissipation: Lubricants perform a function of heat removal, aiding in the control of Temperature during work to prevent overheating.

Wear Protection: Lubrication’s shielding effects help lessen the direct contact between metal surfaces, hence the wear and tear.

In conclusion, however, the correct lubricant that corresponds to the working conditions, such as speed, load, and temperature, among others, can make the bearing suitable, more effective, and more durable.

How Bearing Manufacturers Define Precision

According to the bearing manufacturers, precision is achieved through compliance with stringent standards and specifications regarding dimensions, tolerances, and consistency of performance. The best subject sites state that these specifications allow the bearings to operate under load, speed, and environmental limitations simultaneously without failure. A few of the relevant technical aspects which the manufacturers pay attention to include:

Dimensional Accuracy: This allows the design of specific bearings to be minimized, as a bearing’s application would be ideally within its dimensions, limiting unnecessary motion or friction.

Surface Finish (Roughness): A way in which surfaces are made smooth to reduce friction and wear, which is very important in high-speed applications.

Roundness and Concentricity: This is one of the important features of bearing accuracy. It allows loads to be spread evenly across the bearing, which, in practice, cuts down vibrations and noise made by the operation.

Clearance and Preload: Adequate internal clearance, or preload, helps the bearing function properly in those temperature and speed ranges.

Material Quality: The quality of the material used has a great effect. Bearings built with high-quality materials have great resistance to stress and environmental influences, translating to enhanced bearing life and reliability.

Adhering to such parameters will ensure that manufacturers’ bearings are operationally precise and able to provide consistent and reliable functions across many applications. These specifications are based on empirical evidence from some of the industry’s leading resources, which only serves to affirm their importance in bearing manufacture.

Are ABEC Ratings the Only Factor in Bearing Selection?

Other Factors Influencing Bearing Performance

Throughout my academic endeavors, I examined bearing performance determinants other than ABEC ratings on three websites from Google.com, focusing beyond the typical ABEC ratings. Several crucial elements come into play:

Load Capacity: Bearings can withstand both axial and radial set loads without warping. According to the websites, choosing the right load rating bearing for a certain application is an important factor in reliability and life.

Lubrication: Of course, proper lubrication minimizes friction and wear, which is frequently discussed on these websites. It is also quite important to choose the right lubricant, be it oil or grease, to keep performance within limits and avoid overheating.

Operating Temperature: Bearings require a predetermined minimal and maximal temperature to function properly. The bore and outer rings operating at high temperatures ensure that the bearing will not expand too much, and vice versa for low temperatures.

Speed Rating: Speed capacity is the primary limitation for every bearing type. As stated in the research, attention to the working speed of the application is necessary as it can lead to overheating and efficient functioning of the device.

Environmental Conditions: Environmental factors such as moisture, dust, and corrosive materials can even be detrimental to bearing performance. Many websites have noted that utilizing bearings built for certain conditions can even improve reliability and service life.

Taking these extra parameters into consideration makes these concrete bearing selections possible, which will enable the efficient delivery of performance at a much longer service period in different scenarios.

The Importance of Bearing Maintenance and Care

Latest on bearing maintenance care elaborated by several sites include the following, among others:

Regular Inspection: Periodical inspections help detect concerns or anomalies at an early stage. When checking such websites, one must also perform a visual examination of the bearing for corrosion, abnormal noise, or unusual vibration to avoid abrupt failures.

Proper Lubrication Practices: During maintenance, it is also important to ensure that the bearings are sufficiently lubricated. Some websites suggest that the correct type and dosage of lubricant should always be applied to reduce overheating, which is likely to lead to premature bearing breakdown.

Environmental Control: Bearings must be avoided in all environments that are likely to be contaminated or operate outside the design conditions. The recommendations differ according to humidity, dust levels, and temperature since various bearings are designed to function in different environments.

Correct Installation and Handling: The sites highlighted appropriate installation methods that help avoid misalignments or imbalances that may compromise the operation. To avoid damaging the bearing, the correct methods and tools need to be employed for the particular activity.

Monitoring Operating Conditions: Periodically taking operating readings, such as temperature, and modifying them should be done frequently to avoid carrying out repairs. These tools can help monitor parameters of interest to prevent exceeding mandatory limits on numerous web pages.

Adhering to the guidelines provided by extensive research and experts in the field can achieve significant efficiencies, improved bearing life, costs, and reduced downtime.

Exploring Alternative Rating Systems and Standards

The first three websites listed in Google have provided some helpful information on what alternatives can be used in rating systems and standards for bearings. Slightly differing opinions are presented on crucial technical parameters.

First, a specific identification number for Dynamic Load Rating (C) again appears. This number determines the bearing’s life and static, radial, and axial load-carrying capacity. Most sites rank C values as better suited for gauging the bearing’s endurance.

Next, a specific identification number for Static Load Rating (C0) comes along. It helps in determining the axial and radial non-rotating loads that a bearing can handle before being permanently deformed. Thus, this helps in selecting proper bearings for suitable applications.

The final issue concerns the operational parameters of bearings and their rating in relation to speed. This rating enables the engineer to know the maximum design speed of the bearing to avoid overstressing it, which could lead to overheating and eventual mechanical breakdown. Integrating these parameters with operational requirements is the emphasis of these trusted providers.

In summary, by tailoring selection criteria with these technical parameters, as recommended by established web sources, one also meets performance expectations and enhances the efficiency and service life of bearing applications.

Frequently Asked Questions (FAQs)

Q: What does the ABEC rating mean to the performance of skate bearings?

A: The Annular Bearing Engineering Committee developed the ABEC rating to measure various bearings’ precision and tolerance levels. From this perspective, the performance and speed capability of skate bearings are highly influenced by the higher ABEC ratings, such as ABEC703.

Q: What about an ABEC 9 bearing? How do others rate it?

A: The ABEC 9 bearing is considered to have one of the tightest tolerances, allowing it to be adopted easily in precision and speed-demanding applications. Yet, these are not the most useful numbers for skateboards, as the better tolerances are likely to make no difference in performance compared to lower numbers such as ABEC 5 or ABEC 7 for skating applications.

Q: Do skate bearings get labeled as precision without an ABEC rating?

A: Yes, skate bearings can achieve precision bearing status due to other factors like material quality and manufacturing sources even when no ABEC rating is available. However, their measurements may not be perfectly in line with the ABEC system, as some skate brands implement their own rules regarding tolerance levels.

Q: What is the value of tolerances for different ABEC classes in micrometers?

A: The dimensional tolerances per ABEC class are stated in micrometers. To generalize, the ABEC1 class has more tolerance compared to the ABEC9 class, which has less. This will impact the bearing’s performance to a certain extent.

Q: Why may a skater choose an ABEC 5 bearing rather than an ABEC 7 bearing?

A: The primary reasons for choosing a lower-rated (ABEC 5) arm bearing include cost and durability. A lower-rated arm bearing would make the work environment easier, but for optimal performance, an ABEC 7-rated bearing would be more suitable.

Q: In terms of ISO 492 standards, how do ABEC ratings and ABEC standards differ?

A: The ISO 492 standard states the dimensional and running accuracy of ball bearings in practice. It includes ABEC standards as well. It comprises two systems that work together to relate to the precision of bearings but operate to varying degrees.

Q: Do ABEC ratings have a bearing on what lubricant is used for bearings?

A: The ABEC rating is entirely used for the dimension of the ball bearing but not for the lubricant used on the ball bearing. Nevertheless, maintaining the appropriate lubricant is imperative for preserving the rated ABEC performance and increasing the lifetime of bearings.

Q: Do you believe there are any old myths concerning ABEC ratings?

A: Yes; an example is that users generally believe that high ABEC ratings are better for skating. While high ABEC ratings, like ABEC 7 or 9, represent more precision, their real velocity is more dependent on the quality of the lubricants used and the design of the bearing itself.

Q: How does the American Bearig Manufacturers Association contribute to establishing ABEC standards?

A: The American Bearing Manufacturers Association (ABMA) is an organization that is interested in the processes that give birth to bearing standards like ABEC. Their role is important in sustaining the credibility and dependability of the rated ABEC bearings through various practices.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8