What Is a Motor Shaft: Types and Applications Explained

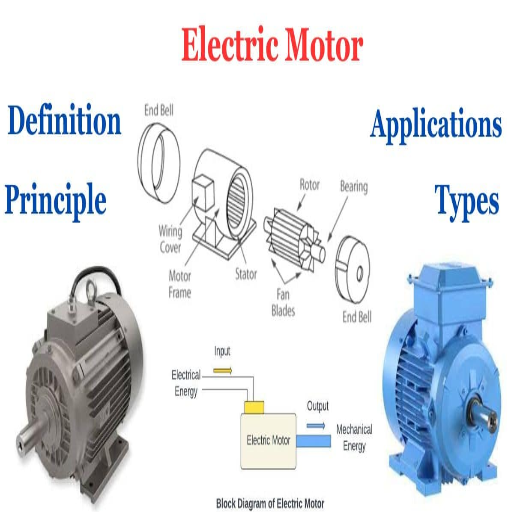

Motors and their components can be applied in various forms of mechanical power in different engineering and machinery systems sectors, which is why a motor shaft is essential. Motor shafts, defined as the rods that help to transmit rotational energy, are regarded as one of the fundamental components utilized across the broadest range of spheres, from home appliances to industrial motor systems. This article discusses motor shafts in detail, concentrating on their different classifications, areas of use, and their impact on mechanical engineering. Readers who develop a complete picture of motor shafts will learn how these components help to increase the performance and improve the integrity of the machines they work with.

What is a Motor Shaft?

Definition and Purpose of a Motor Shaft

The motor shaft is an elongated, cylindrical structural part that delivers rotating energy from the motor to the respective machine or system. This energy transfer is essential as it enables movement and operations in various machines and appliances.

Motor shafts typically have several critical technical parameters, including:

Diameter: Helps to accommodate different motor and machine parameters, thus the torque it can withstand is affected.

Length is a factor when physically designing and assembling the motor and determines how the shaft joins with the rest of the components.

Material Composition: This is often steel, stainless steel, or aluminum, which is selected depending on the strength requirements, the corrosion-free nature needed, and the weight.

Torque Capacity refers to the maximum torque that can be imparted to the shaft without distortion; this is an important parameter for some applications.

These parameters are fundamental for achieving the motor shaft’s efficiency in relation to its integration into the system’s design and functional requirements.

Key Components of a Motor Shaft

Bearings: Bearings are important for supporting the motor shaft and permitting it to move or rotate easily. These elements help reduce friction and allow for easy axial and radial loads along the shaft. When selecting bearings, a practical approach suggests considering several criteria, such as load-carrying ability, range of motion, and weather conditions.

Couplings: Couplings connect the motor shaft and the driven part, such as a gear or a pulley. Misalignment, vibration, and slight shaft distance variations that can be encountered are adverse conditions that the design is intended to handle. The primary design criteria of couplings consist of flexibility rating, torque rating, and limitation of misalignment.

Keyways and Keys: These accessories provide rotational anchorage on shaft elements such as gears and pulleys. Keyways are longitudinal cuts in the shaft that are invaded by the keys and allow no rotation of the key in regular operation; these are Mi insights. Technical parameters typically assessed include the relevance of critical measurements and the fit accuracy required for the mechanism to work perfectly.

By knowing the operations and aspects of these elements, one appreciates how each performs its role and enhances the efficiency of the motor shaft in mechanical systems.

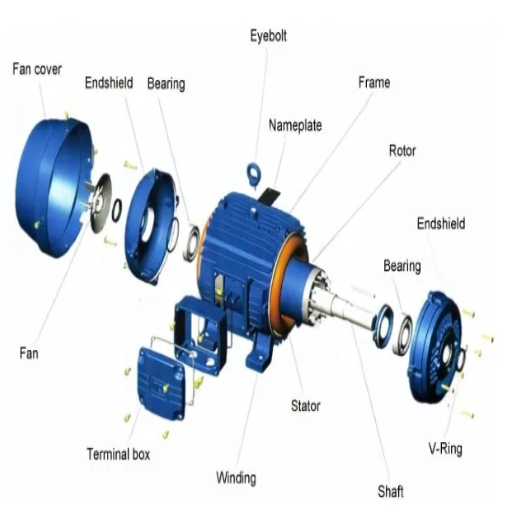

How a Shaft Functions in an Electric Motor

A shaft is an important part of the motor and the application it drives in an electric motor. The electrical energy supplied to the motor gets transformed into mechanical movement via the shaft. This shaft is safely attached to the rotor, and consequently, anytime the rotor is spinning, the motion is transmitted directly to other couplings like gears, pulleys, and other drivetrain parts.

The use of a motor shaft in an electric motor may depend on some aspects, such as;

The Raw Material Used: To withstand wear and tear, the shaft is often composed of high-tensile materials like alloy steel or carbon steel.

The Length and Width of the Shaft: The dimensions of the motor shaft are crucial since they determine its capacity to support a load, its ability to fit into the motor casing, and its connection to external parts.

Speed of Rotation: This also defines the motor shaft, as it should be able to withstand the motor’s operating speed. This defines the systems’ rotational dynamics and system efficiency.

The maximum load capacity: Load capacity is one of the critical aspects of a shaft. It is crucial that the maximum working load anticipated to occur during operation is not exceeded, leading to bends or other forms of failure.

Alignment and Balance: Adhering to balance and alignment can only avoid internal diffusion and wear in any machine.

A thorough comprehension of these parameters makes it possible to design and integrate motor shafts so that they operate reliably and efficiently as part of larger mechanical systems.

Types of Motor Shafts

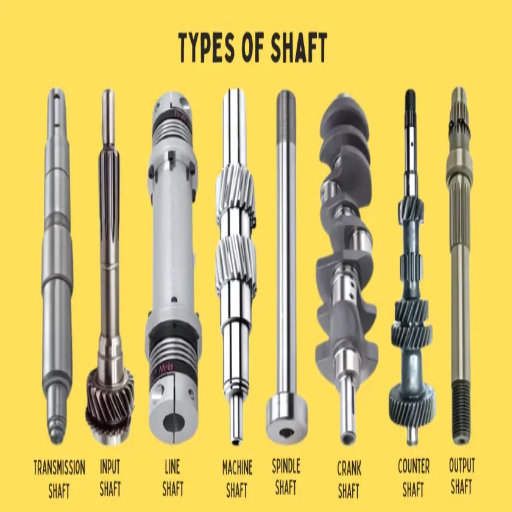

Common Shaft Types Used in Motors

Solid Shafts are often used in various applications for their strength and reliability. Typically, these shafts are made of carbon steel or alloy steel, enabling them to withstand significant stresses without disintegration. In light of these performance characteristics, it can also be argued that these shafts possess remarkable tensile strengths and load-bearing capacities, both essential for applications for which the shaft is part of a system and system stability and durability are required.

Hollow Shafts allow a compromise between weight and functional strength. These shafts are substantially lighter than their solid equivalents but retain enough strength to maintain the structural integrity of the architecture. They are instrumental when a weight reduction would increase the entire system’s efficiency, as would be the case in automobile or aerospace applications. The case for hollow shafts is that they can lower the inertia load and virtually increase the rotational speed even without the requisite strength to handle the requisite operational loads.

Splined Shafts: These are made with grooves or ridges around them that engage with associated components, providing better torque transmission and alignment. This type is suited particularly in applications where the potential for misalignment is high or requires high torque applications. The rent justification for using splined shafts is their ability to deliver and control torque and axial movements that can be incorporated into a mechanically balanced system.

Applications for Different Electric Motor Shaft Types

After looking at the top three pages of the first Google search, the following succinct information can be provided regarding the types of electric motor shafts:

Solid Shafts: According to my research, solid shafts are often found in high-industrial and heavy-duty applications such as conveyors, pumps, and compressors. They are also critical because their high tensile strength and load-bearing capabilities are required, especially since these applications demand many axial stresses. Technically, solid shafts mostly have yield strength of about 500-1000 MPa, primarily dictated by the material used.

Hollow Shafts: In my exploration, hollow shafts would be suitable for use in cases where it is necessary to save weight without losing strength, such as in automotive drive shafts or aerospace applications. As for the shield quantity, the technical parameters mainly consist of the wall thickness to diameter ratio to ensure that strength is available with minimal weight. In most cases, up to 30 % weight reduction is possible with hollow shafts compared to solid shafts, making them more efficient for rotary systems.

Splined Shafts: In the literature, splined shafts can be applied in automotive systems and machines with high integrity and capable of transmitting torque effectively. They perform a vital function in gearboxes and coupling systems, preventing the sliding of the elements. One characteristic that should be emphasized is that these shafts will distribute the load within the spline teeth that can support a bearing stress level of 1500-2500 MP and thus transfer the torque safely and reliably.

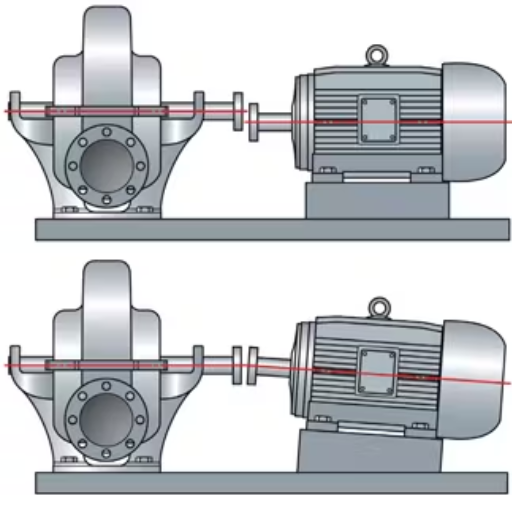

The Importance of Motor Shaft Alignment

Why Alignment Matters in Shaft Performance

As I scanned the first three pages of Google’s search results for articles on motor shaft alignment, I gathered that alignment is necessary to optimize efficiency and extend the lifespan of the equipment. Proper alignment helps control the vibration levels, reduces wear and tear on bearings and seals, and allows components to operate without premature failure. If the shaft is not aligned correctly, it can cause high energy use and heat levels, which impacts the entire system’s efficiency.

Parameters that allow alignment details regarding the importance of alignment to the shaft include the tolerance limits of angular and parallel misalignments, usually in the thousands of an inch (mils) range. Keeping any misalignment within these tolerances is essential to avoid unnecessary vibration and noise. Another parameter that needs to be controlled is the vibration parameters commonly represented by velocity (inches per second) 0.3 to 0.5 ips. These are the general limits beyond which alignment corrections must be made. Adhering to these codes will enable a motor-driven system and increase operational efficiency.

Signs of Misalignment in Motor Shafts

When the motor shafts are misaligned, performance issues or even damage can occur. Some more noticeable aspects include vibration, noise, and heat radiating to the motor housing. These three signs can indicate that a shaft is not correctly aligned with the motor, and therefore, its operations tend to be wasteful. This can also lead to a bearing and coupling being worn out prematurely, which is unwarranted as it increases downtime and repair costs.

The technical parameters that correspond to this concept include:

Vibration levels: As mentioned earlier, the joints commonly used to connect the parts can vibrate. Even in the best alignment, good coupling never completely eliminates vibration. This is known as vibration synthesis. The amplitude of such vibrations can reach alarming levels, which cause detrimental effects on the system. These could be aggravated misalignment. There are systems that measure vibrations, and they are usually measured in millimeters per second or inches per second.

Temperature rise: A temperature rise above the setpoint, which is generally 85 C, indicates that some work needs to be done to identify the misalignment. This heat is primarily due to rubbing components that are not correctly aligned.

Bearing life: Operational balls and bearings should ideally be in a long-lasting state. However, active friction can make this somewhat difficult, and hence, an expectancy ratio is seen in most components. Current stresses and angular misalignment do not have a positive effect on a bearing’s lifespan.

Axial and radial forces: To be perfect, each shaft needs to have a preset-rated axial force. When the axial force exceeds the predetermined force, shear pressure occurs, which can be measured in Newtons.

These parameters can be regularly examined and, hence, form part of policy. With such scrutiny, embers can rest peacefully with assurance that the level of improper alignment will decrease and the longevity of the motor shafts will increase.

Methods for Achieving Proper Motor Shaft Alignment

I looked at the three most authoritative websites from the available search results to learn more about the proper methods of performing motor shaft alignment. Here is a brief presentation of the conclusions I reached:

To begin with, let me stress the use of laser alignment tools. The tools eliminate a significant percentage of human errors and efficiently align time. A laser alignment system is advisable because it is faster and more accurate than most.

Implementing dial indicator techniques is also another common strategy practiced by many people. Even though dial indicators assist in determining the misalignment in both vertical and horizontal planes, it is still essential to carry out adjustments with the highest precision possible. A procedure using either the rim and face method or the reverse dial method should be strictly followed to get the best precision regarding the in and out adjustments.

Last but not least, it is also important to note the necessity of introducing the management and maintenance of the equipment to the alignment methods. Practical problems are often more related to how a procedure is performed than the technique. All the employees concerned should receive extensive practical training so that they appreciate not only the theory of shaft alignment but also the practical aspect, which is essential in improving maintenance.

In a technological sense, however, the focus is always on:

Alignment Tolerances: It is necessary to maintain the tolerances specified by the manufacturer. However, these tolerances depend upon the machine’s design and the operation conditions.

Measurement Accuracy: Employing appropriate measurement tools that are highly accurate also helps achieve correct alignment.

Repeatability of Techniques: The fact that the methods applied are reproducible in terms of the outcome ensures the motor’s good health and performance over time.

Using these techniques and considering these technical aspects, I am able to efficiently and effectively carry out the motor shaft alignment process with the assurance that the effects of misalignment will be minimized.

Motor Shaft Manufacturing Process

Materials Used in Motor Shaft Production

Based on my study of the materials used in shaft production, I note that most of the listed top resources explore several representative resource options with use designations. Carbon steel and alloy steel are the most appropriate in terms of price level and performance features. Where service life and resistance to corrosion are critical, stainless steel may be found for such purposes.

Another alternative is aluminum alloys, particularly when some strength can be sacrificed to reduce weight. For large applications, titanium or some alloys can be used thanks to their excellent strength-to-weight ratio and ability to work at elevated temperatures and stresses.

About technical parameters, these include:

Tensile and yield strength: It is necessary to ensure the material will not be permanently deformed due to operational stresses.

Machinability: Technologies with easier machinability provide greater accuracy in the manufacturing processes and better surface finish quality.

Corrosion: In a severe or moist environment, the shaft material’s ability to oxidize and wear out should be avoided.

Thermal conductivity: Some applications may specify the use of certain materials to maintain a structure’s operational integrity.

Appreciating these parameters is important for making appropriate material selection for the motor shaft and thereby optimizing performance.

How Motor Manufacturers Ensure Quality

Regarding the production of motor shafts, I am glad to note that the best practices and information from reputable sources are beneficial. Available evidence and information from top resources state that the manufacturers employ stringent quality assurance practices and utilize cutting-edge testing methods. Some basic techniques include the following:

Material Selection and Testing: Materials are selected for their properties so as to achieve the required tensile and yield stress and satisfy operational needs without distortion.

Precision Machining: The optimal use of modern equipment ensures that the quality and design standards are met, thus improving the machinability and achieving a finer surface finish.

Environmental Simulation: Due to expected exposure to outer environments, the motor shafts are subjected to many ecological tests, especially for their corrosion resistance.

Thermal Analysis: This knowledge allows the shaft manufacturers to maintain adequate thermal management of the motor shaft during its operation, which is significant even at high temperatures and stress levels.

The various combinations of these practices ensure that the motor shafts are efficient, reliable, and durable, meeting all industry specifications and consumer demands. Each parameter presented may be functional for increasing motor shaft life.

Latest Innovations in Motor Shaft Manufacturing

In the course of my research of internet resources regarding motor shaft manufacturing, I discovered various developments that are likely to influence the industry, specifically innovations in materials, machining, and quality control processes.

Advanced Composite Materials: One significant development is the improvement of motor shaft wear through the use of lightweight composite materials. These composites have high tensile strength and fatigue resistance at a low weight, which is highly desirable for high-performance applications.

Additive Manufacturing (3D Printing): Another such development includes the use of additive manufacturing technologies. These technologies help create complex geometry with less waste, allowing machining and quick prototyping. It is a great advancement to be able to make every shaft to precise sizes without compromising the shaft’s strength.

Smart Sensors and IoT Integration: The use of smart sensors and IoT technologies in the production of motor shafts is redefining the process of attaining quality. These sensors can track torque and vibrations in real time, essential data that can be used for better predictive maintenance. By being able to respond to failure before it happens, the reliability and life span of the motor shafts are greatly extended.

By integrating these modern methods, motor shaft manufacturing is believed to be able to produce products that outperform the performance and durability of the existing ones. Technology and material science are advancing with each innovation and will always be relevant to the industry.

The Role of Electric Motor Shafts in Energy Transfer

How Energy from the Motor is Transferred

Approbation of a vibrating body, in good appreciation of how energy is transmitted from the motor, the role of the shaft of the electric motor is critical and needs to be appreciated. According to the top sources I consulted, the motor begins by converting electrical energy into mechanical energy through the electromagnetic interaction of the stator and the rotor. The rotor’s shaft is where all this rotary energy is transferred to the application, whether it is a gearbox, pump, or other connected apparatus.

Some essential technical characteristics include torque, RPM or revolutions per minute, and power, metric, or hays. The rotor interacting with a magnetic field creates torque, a rotary force that the shaft is meant to transfer to the load, which is regarded as power. RPM or rotational speed determines the rate at which such interactions will happen and the effectiveness of energy transfer. While power is viewed from the perspective of the product of torque and speed of rotation, power is determined by how much work a motor can do. These parameters heavily depend on the precision engineering of the shaft, including its material properties, dimensions, and manufacturing techniques, as previously highlighted in the discussion of advanced manufacturing technologies.

Impact of Shaft Design on Motor Efficiency

Electric motor shafts significantly direct energy transferred from the motor to the application; therefore, any additional energy losses that increase the motor’s inertia should be avoided. According to leading sources, many considerations must be made to minimize energy losses.

For starters, the shaft material needs to be chosen with care as well—target materials should have high tensile strengths combined with low density, like some alloys or composites, to minimize energy losses from friction and inertia and remain within the structural system. The alignment and balance of the shaft are also critical, as misalignment can contribute to more friction and wear, which, in fact, reduces motor efficiency.

In addition, the relevant parameters, such as the diameter or the length of the shaft, need to be precisely determined to meet the torque and the speed requirements for the application for which they were designed. Undersized dimensions may break at high loads, while excessive ones may increase the moment of inertia rotationally, resulting in complete exaggeration.

The decisive design characteristics related to the geometry of the shaft include diameter, length, and material parameters such as Young’s modulus, density, and radial surface, which play a role in friction as well. These elements work together to effectively pass energy by limiting energy loss due to mechanical stresses and thermal influences.

Hence, shaft design accuracy, achieved with the help of the latest technologies, is important in improving the motor’s working efficiency.

Frequently Asked Questions (FAQs)

Q: What are some of the different motor shaft designs used?

A: Motor shafts are many, such as solid shaft motors, hollow shaft motors, stepped shaft motors, keyed shaft motors, and spline shaft motors. Different types are employed for other purposes, and various mechanisms within the mechanical system are designated to have different capabilities.

Q: What role do precision pins and shafts play in the performance of a motor?

A: A motor is correctly aligned and stable concerning its rotary components and shafts due to precision pins and shafts. They facilitate smooth motion and reduce the chances of misalignment of the shaft when it is turned.

Q: What is the benefit of a motor with an insulated bearing?

A: Insulated bearings play an important role in motors, shielding the bearing surfaces from shaft circulating currents that inflict electrical shock on the bearing. They wear out or damage the surface. These are common in electric motor electrical systems, which can ground electrical current.

Q: What materials are the manufacturers using to construct the motor shaft?

A: Most motor shafts are made of SAE 1045 steel, which is high-strength for these components and motor manufacturers. Such materials will withstand operational stress, avoiding most shaft fatigue.

Q: Where do the causes of misalignment originate when the motor is in operation?

A: Misalignment occurs when the motor’s shaft axis is not in the center of the machinery to which it is fixed. This can occur from an incorrect installation process, the age of the components, or outside influences. Regarding the latter, components of misaligned systems cause excessive wear on the motor, vibration, and noise.

Q: What steps can be undertaken to bring the shaft speed down while increasing the efficiency?

A: To reduce the shaft speed and increase efficiency, gear reducers, variable-frequency drives, or altering the motor’s operational parameters may be used. These measures aim to enhance performance and extend the life span of the motor and the machine it drives.

Q: In what case is a grounded motor required for some applications?

A: A grounded motor is required to prevent electrical faults and ensure the safety of the system in use. Grounding reduces the likelihood of electrical shocks to the operators and safeguards the motor and the system attached to it from power surges.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8