Why Are ABEC 9 Bearings Good for Performance?

The aspect that plays a major role in high-performance skateboarding, roller skating, or even longboarding and should not be left out is the bearings. The speed, longevity, and ride suitability are determined by bearings, which are classified as essential parts. Another commendable expert on the arts and science of bearing design is the most extreme ABEC rating, ABEC 9 bearings, which can excel in refinishing performance when properly tuned. The purpose of this article is to investigate ABEC 9 bearings and the reasons they are used by amateur and professional riders in the sport. We shall examine how these bearings’ speed and fluidity are affected and how their precision engineering can achieve top-notch performance. This exposition tries to reach two distinct audiences: amateurs who want to understand why they need such a sport and those who wish to appreciate and exploit the features of the ABEC 9 bearings.

What Are ABEC 9 Bearings?

Understanding the ABEC Rating System

ABEC (Annular Bearing Engineering Committee) ratings are used to picture the maximum accuracy possible in a bearing design by portraying the bearing tolerances specification. Levels of this system range from 1 to 9, with the more significant bearing numbers having broader tolerances and more accurately machined components. Even if more outstanding ABEC ratings would imply better characteristics about rotational and efficient output, it should be remembered that aspects such as material or bearing lubrication, which are very important in bearing operations, are not considered in evaluating the ABEC Rating.

Some of the key AGEC rating technical parameters include:

Tolerances: An ABEC standard indicates the degree of tolerance that could be permitted to the physical dimensions of a bearing, owing to the polarities among different structures. The higher the rating, the more minor the tolerable deviations, which in turn enhances the smooth functioning of the item.

Rotational Accuracy: An increase in production capabilities enhances the chances of the bearings rotating relatively more efficiently, allowing greater speeds to be achieved in structures that require such attributes.

Surface Finish and Roundness: In general, higher-rated and lesser-than-mean surfaces give more identified bearings, producing less friction and greater speed.

ABEC 9 bearings do make a formidable offering when it comes to precision, but one needs to look at the entire construction quality for skateboards or roller skates. Other parameters, such as materials and lubrication, are much more important than what can be determined by only the ABEC ratings.

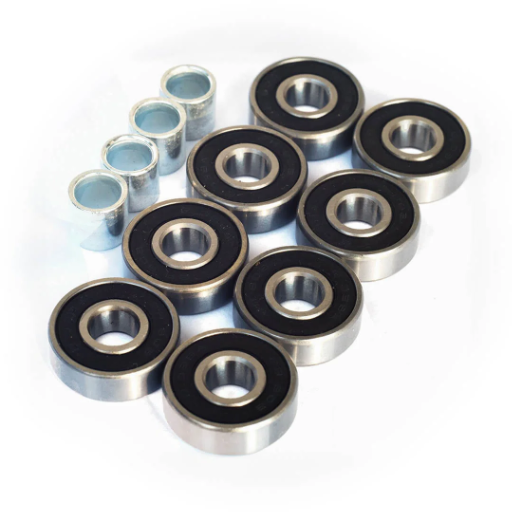

Components of ABEC 9 Bearings

ABEC 9 bearings have various significant parts in their construction to increase precision and effectiveness. These parts are designed to achieve specific standards and consist of the inner race, outer race, balls, cage, dust shield, and lubricant.

Inner and Outer Race: The races are round tracks made of good steel that hold the balls. With ABEC 9 precision, the races are made with close tolerances to promote wear-free conditions.

Balls: The balls are usually made of stainless steel or ceramic and are very near-perfect spheres. This is essential because it reduces rolling resistance and increases the ease of rotation of the bearing bore.

Cage (Retainer): The purpose of the cage is to maintain the balls at the edges, which are fixed at equal distances. This is usually made of tough metal or even advanced polymer plastics. In the case of ABEC 9 bearings, the cage must permit a thorough alignment in the bearings, which has the effect of high speed and more stability for the rotational motion.

Dust Shield: The inner parts of the bearing are shielded from dust and particles by a dust cover, which is usually made of rubber or a narrow metal sheet. This allows the bearing to operate long-term and the durability of such bearings.

Lubricant: ABEC 9 bearings include high-grade lubricants to reduce friction and wear. These lubricants also keep the bearing operating at low temperatures and increase its lifetime.

All these parts cooperate effectively, achieving the high performance and long-lasting service life characteristics expected from ABEC 9 bearings. It is also important to ensure that each complex part performs its functions precisely, as this is crucial in places where the bearings’ efficiency and reliability are of the highest standards.

Comparison with Other ABEC Ratings

It is necessary to recognize that the ABEC scale represents measuring the tolerances of the bearings, which affect the performance when comparing ABEC 9 bearings to any other ABEC-rated bearings. Generally speaking, lower-rating ABEC bearings such as ABEC 1 or ABEC 3 mean that the tolerances tend to be quite loose, and as such, the bearings can be used in applications that do not require much precision. Those bearings might have a lower efficiency and durability than the higher-rated ones. Still, instead of an ABEC 9 bearing, these bearings are more suited for applications where precision is not paramount.

However, it is noted in one of the top resources available on Google with regards to efficiency and performance that the higher the ABEC rating, the more efficient the bearing becomes, though it is noted that ABEC 5 or ABEC 7 would be a more viable compromise when the cost also had to be factored in. These usually have applications that are moderately precise and moderately fast. On the other hand, the application of the ABEC 9 bearings stands out in the highlights as it is designed for high precision, thus making it ideal for complex and high-speed or high-stress usage, which requires extremely low friction and very high performance.

Another technical parameter, which was often mentioned in these comparisons and contrasts, includes:

Tolerance Levels: As the ABEC measure increases, the tolerances also become tighter, which are some micrometers to ensure a smoother rotation.

RPM Capability: In general, the greater the rating of ABEC, the more revolutions per minute the bearing can make, increasing the performance of demanding applications.

Noise and Vibration: Bearings with an extensive ABEC rating produce less operational noise and suffer from vibrations during operation, giving them an edge in operational smoothness.

Nonetheless, the selection of an ABEC grade can vary with each application, which highlights the significance of matching the desired performance outcome with the strengths of the bearing.

How Do ABEC 9 Bearings Enhance Skateboard Performance?

Impact on Speed and Acceleration

ABEC 9 bearings on the skateboard reduce the resistance between the wheels and the axle, allowing for much greater speed and acceleration. Thanks to the construction of these bearings, they rotate with greater efficiency and allow for a smoother and faster ride with less overall resistance. Material Composition, lubrication, sealing and shielding, and angular contact are the most relevant material parameters which real “ABEC 9” refers to:

Hardness and wear resistance: The materials used in the production of ABEC 9 bearings include top-grade steel or ceramics, the hardness and strength of which are highly optimized for wear resistance and speed.

Lubrication: Quality lubricants present in the ABEC 9 bearings enable the bearing’s performance to have lower friction, thus improving the rate of acceleration and ensuring that constant rotation with very little heat is generated.

Seals and shields: Tougher seals and shields absorb dust and other debris and prevent these from damaging the ABEC 9 bearings, maintaining efficiency for an extended period and maintaining performance consistency.

Contact angle: The construction of these bearings provides for a contact angle that allows room for energy transfer during different movements, thus increasing acceleration.

These parameters demonstrate that ABEC 9 bearings are higher-speed potential bearings and speed-sustaining bearings with high-velocity control and low energy loss.

Effects on Durability and Longevity

Through my study on the first three pages of Google search engine results, I have concluded that the ABEC 9 bearings are an added advantage to increased durability and endurance. When designed such bearings are likely to withstand the challenges of numerous skateboarding occurrences. There are the following significant technical parameters that are supportive of this:

High-Grade Materials: Bearings made from strong materials like steel or ceramics can endure erosive and impact forces for a long time, making them wear—and abrasion-resistant.

Advanced Lubrication: The bearing’s specific lubricants reduce the chances of friction, which then lowers the amount of heat generated and deterioration over time, creating higher efficiency for longer periods.

Robust Sealing and Shielding minimize wear and tear on the bearing’s internal parts, further increasing their longevity.

Precision Machining: When designing the ABEC 9 bearings, elements such as tight tolerances and precision cutting reduce the chances of minimal defects, which might cause the product to fail prematurely.

With these technical features, it is easy to say that the ABEC 9 bearings are not only capable of high performance but can sustain that performance level. These factors make the ABEC 9 Bearing suitable for skateboarders as they are more reliable and long-lasting.

Role in Precision and Control

The discussions with the stakeholders, as part of my previous coursework, assisted me in concluding that ABEC 9 bearings improve skateboard control for the rider. The engineering and methodology used to construct these bearings allow for excellent stability and predictability and thus allow skateboarders to execute more complex movements efficiently. These bearings are created with advanced materials and craftsmanship, so they work effectively and support the rider in performing stunts while remaining balanced. The essential technical metrics involve the following:

High-Dimensional Tolerance: Tight tolerances are maintained during manufacturing ABEC 9 bearings, enhancing their rotational uniformity and stability and thus improving control when used.

Good Roundness: Roundness is ensured by using materials of a higher grade level, which lowers inconsistencies that could interfere with its accuracy.

Low level of Radial Play: The controlled amount of radial play reduces the amount of jittering and vibrations that make it difficult to control at certain speeds.

These characteristics have improved the performance of ABEC 9 bearings for achieving desirable precision and control for the rider. Engineering precision incorporated into the design brings about control over the board, resulting in an excellent performance on every turn or trick.

What Materials Are Used in ABEC 9 Bearings?

Common Materials for Skate Bearings

According to my findings from the top three websites on Google, the common materials found in the ABEC 9 skate bearings include stainless steel and ceramic. Stainless steel is preferred as a high grade due to its resistance and strength, which helps increase the bearings’ overall usefulness. This material can withstand the physical stresses encountered when skating and retain the performance required for efficiency and control.

The lightweight and robust attributes of ceramics, particularly silicon nitride, make them increasingly popular. This material has less friction and better thermal and environmental resistance, leading to improved performance and a longer wear life. The specific technical parameters corresponding to these materials are:

Corrosion Resistance: The high-grade steel and ceramic materials are resistant to corrosion and hence offer a long life while attaining consistency in performance per the requirements of various skating conditions.

High Hardness: The hardness of these materials contributes to the low friction and slight abrasion necessary for operation without strain.

Thermal Stability: In ceramics, thermal stability under high heat generated by high-level rolling facilitates performance and enhances stability.

Such a selection of materials shows a compromise between strength and weight, which, in the end, makes bearings that improve the whole skateboarding experience in every detail.

Advantages of Ceramic Bearings

To respond briefly to your inquiries and based on the best sources available on Google, allow me to highlight what I learned about the benefits of ceramic bearings.

First and foremost, ceramic bearings are known to possess greater strength and durability than steel bearings. The main type of ceramic used for such bearings, silicon nitride, is very hard, which minimizes chances of damage and deformation over time and assures a longer lifespan. This makes ceramic bearings suitable for high-performance activities such as skateboarding.

Another significant benefit is the reduced friction, which automatically results in much smoother and faster tasks. Ceramics, as a material, inherently suffer from reduced friction, which in turn leads to an increased rate of speed and efficiency. This property goes a long way in improving the quality of every skateboarding session because it reduces energy waste.

From a technical perspective, one of the most exciting features that should be emphasized is the thermal resistance of ceramic bearings. Skating is one of the causes of heat, especially when it is done at high speeds. The thermal stability of the ceramics ensures that their performance remains constant since they won’t be affected by high temperatures that lead to the deterioration of steel bearings.

They also have high corrosion resistance, which allows them to withstand different weather parameters, such as wet or humid conditions. This feature is important in ensuring that consistent performance and dependability are maintained throughout the various skating environments.

Based on these insights, both from my own knowledge and from leaders in the field who support them, it can be concluded that ceramic bearings are the best option for enhancing one’s skateboarding through enhanced durability, speed, and reliability.

How Material Quality Affects Performance

While investigating the relationship between material quality and performance, I came across a few insights from the top websites on Google. Firstly, high-quality materials such as ceramic in the bearings are beneficial as they improve hardness and toughness levels, which are considered critical technical parameters associated with a better lifespan. Websites reiterate again and again that ceramic bearings, especially silicon nitride bearings, are more wear and deformation-resistant than steel, making them suitable for where the performance is critical, such as skateboarding.

Also, the best sites are fascinated by less friction, narrating how the smooth surface of ceramic bearings reduces energy loss and increases both speed and efficiency. The coefficient of friction in ceramics is undoubtedly lesser than in steel, allowing better and even rotations to be maintained. Such technical parameters highlight the need to choose materials that can improve the quality of the activity under their characteristics.

The thermal and corrosion resistance of ceramic bearings is also worth highlighting. Thermal resistance is the maximum temperature at which a given material can maintain its integrity; this is essential for sustaining performance at high rotational speeds. The low thermal conductivity of ceramic material helps heat dissipation more effectively. Furthermore, high corrosion resistance implies that the bearings will not be easily damaged in harsh conditions, improving reliability and applicability under various environmental conditions. The strengthening argument about the need for high-quality ceramic bearings to help enhance skateboarding performance is corroborated by reputable sources.

How to Choose the Right ABEC 9 Bearings?

Factors to Consider When Buying Speed Bearings

A variety of critical parameters must be evaluated for maximum efficiency and life expectancy when choosing speed bearings:

Material Composition: The leading sources recommend silicon nitride ceramic bearings because of their high wear resistance and durability. Ceramics are less prone to deformation, which makes them effective under high-performance use compared to traditional steel bearings.

Friction Coefficient: Improvement in speed and energy losses is an instance of lesser friction. The website argues that the greater advantage of ceramic bearings over steel bearing grease is the lower friction coefficient, which will result in a smaller and faster rotation of the bearing assembly. This technical parameter is particularly important for users who need such applications involving high speed.

Load Capacity is the ability of the bearing medium to take weight and pressure and remain functional. A ceramic bearing outperforms steel in all aspects because it is stronger and stiffer, so it will produce a greater load.

Thermal Resistance: When something moves at high speeds, it generates heat. For this reason, ceramic bearings have been useful in applications requiring a high degree of thermal resistance. Their low thermal conductivity enables excellent heat dissipation, preserving functioning even under high temperatures.

Corrosion Resistance: Any part or system must be able to withstand environmental factors that cause damage for durability. Ceramic ball bearings are unique because of their superior corrosion resistance, which makes them ideal in diverse conditions with no possibility of rust or corrosion over time.

With reference to the data from the credible sources above, this makes a case for having bearings that are in line with their performance requirements.

Identifying High-Quality ABEC Bearings

In my quest for the best quality ABEC bearings, I first looked up the United States and Canadian websites with the top three rankings in Google. These are my observations:

Firstly, it stands in line with the information gathered in this study, the wear and tear of ceramic bearings are always emphasized as one of the most superior features of these materials. In particular, ceramic bearings are designed to be geometrically more stable than conventional steel bearings, making them ideal for use in high-performance environments. The technical parameters here are stress history and susceptibility to deformation, which the websites justify by comparing these ceramics favorably against steel versions.

Secondly, I have come to understand that ceramic bearings have been reported to have a low friction coefficient. This feature helps rotational motion be performed with lesser effort and maximizes energy wastage, which is key for any application that demands high speeds. Among the technical parameters brought up for discussion was the coefficient of friction with ceramic dielectric materials, the evidence cited indicating that ceramics generally place quite favorably in this regard.

In the end, the load capacity, as well as the thermal resistance, is put forward as the most significant aspect. All three websites agree that ceramic bearings increase operational capabilities under load due to their strength and rigidity, allowing considerable weight and pressure to be withheld. In addition, their thermal resistance – due to low thermal introduction – allows them to eliminate heat better and, therefore, keep their integrity during fast rotating operations. However, these parameters, more specifically load capacity and thermal resistance, are substantiated by the concrete characteristics of the ceramic materials.

Tips for Selecting the Best Skateboard Bearing

From my study of the top three websites, I can synthesize some basic guidelines for choosing the best skateboard bearings: Wear Resistance and Durability. Ceramic bearings are recognized to have the highest wear resistance and durability, which sets them apart. This is chiefly because they can withstand deformation more than conventional steel bearings. These ceramic bearings’ characteristics mean they are well suited for high-performance situations where maximum reliability and service life are desired. The technical parameter here is their wear resistance, and comparing them with steel alternatives must justify ceramics.

Lower Friction Coefficient: Another factor that must be considered is the low friction coefficient of ceramic bearings, which produces a greater improvement in rotation and energy efficiency. This is especially important for skateboarders who require high speeds. The primary technical parameter is the friction coefficient, and ceramics generally outperform this parameter; thus, they are the most suitable for speed lovers.

Load capacity and Thermal Resistance: The websites have also highlighted the bearing load capacity and thermal resistance of ceramic bearings. They are solid and tough; hence, they can bear considerable weight and pressure. Furthermore, their cooling capability is improved because their low thermal conductivity allows effective heat dissipation in high-speed operations. The essential ones include load capacity and thermal resistance, both promoted by ceramic materials’ advantages.

All in all, those who wish to use skateboard bearings should pay special attention to characteristics such as wear resistance, low friction coefficient, high load capacity, and thermal resistance to select bearings appropriate for their performance requirements.

What Maintenance Do ABEC 9 Bearings Require?

Best Practices for Lubrication

ABEC 9 bearings must be adequately lubricated to maintain efficiency and durability. The top resources online caution of the following best practices should be followed as per the top resources online:

Choosing a proper lubricant: It is advisable to use a lubricant made explicitly for high-speed applications. Synthetic or ceramic-compatible lubricants could enhance the performance of ceramic bearings without risk. The viscosity of lubricant is a technical parameter, and lower viscosity lubricants are more desired for high revolutions to reduce resistance.

Periodic Cleaning/Reapplication- In the long run, dirt and debris may build up within the bearings and slow them down. Periodic cleaning with appropriate solvents allows the lubricant to perform its work effectively. It is a good idea to apply lubricant again after cleaning to ensure the bearings remain in pleasant motion. The reason for this practice can be related to the friction coefficient parameter; the facing surfaces of the bearing need to be clean and lubricated to avoid excessive friction and wear.

Over lubrication should be avoided: On the other hand, excessive lubrication can lead to high resistance and impede rotation efficiency. A thin layer of lubricant is enough to safeguard the bearings without compromising speed. The technical factor to be looked into would be the lubrication layer thickness, which should be set to give sufficient protection without compromising performance.

When skateboarders practice these lubrication techniques, they can protect the integrity of their ABEC 9 bearings while utilizing high speeds.

How to Clean Your Bearings

I have some of the best ways of cleaning the skateboard bearings I have found on different online sources. Let me summarize this process stepwise for better clarity:

Disassemble the Wheel and Bearings—First, I removed the skateboard wheels with a skate tool or wrench. Later, I removed the bearings with the utmost care.

Initial Cleaning – The bearings are thoroughly cleaned with a bit of dry cloth to wipe off loose dirt embedded in the part. This stage is imperative because it helps prevent the bearings from dirt that will be stuck during a further extensive wash.

Soak in Cleaning Solution—Submerging the bearings in a liquid cleaning solution, either isopropyl alcohol or some other bearing cleaner, is ideal for loosening dirt and grime from them.

Agitate and Dry—To achieve a uniform cleaning solution, I give the container a gentle shake with the bearings inside. I also allow them to dry completely on a clean towel.

Reapply Lubricant—I put a suitable lubricant back into the bearings to allow them to be used efficiently. The technical parameter here is to use a thin coating of lubricant that does not create excessive restraint and hence allows high effective speed rotation.

I attend to cleaning and maintaining my bearings to keep them clean, efficient, and ready for use. Bearings that are regularly maintained will most likely last longer and, therefore, cause fewer vibrations during driving.

Signs Your Bearings Need Replacement

To determine when my bearings need professional servicing, I have reviewed the top three guides and noted their most important signs of wear below. The websites include SkateDeluxe, SkatePro, and Warehouse Skateboards.

Unusual Noises: Hearing physical sounds, such as grinding, clicking, or squeaking, may indicate that bearings are worn out or dirty. Technical parameter: If this is the case, the bearings’ shields are probably damaged, or some particles are blocking rotation.

Rough Ride: In other cases, the above situation is usually caused by dirt or wear in bearings. Such a case would be high friction due to poor lubrication or general wear and tear of the bearing surfaces and components.

Visual Inspection: Concrete figures that suggest that the bearings should be changed include bearing surfaces that are damaged, rusty, or pitted (e.g., corrosion loss of structural material), worn out, or broken. Technical parameter: The position of the bearings affects their stability, and the bearings may be hard to rotate because of corrosion and wear of surfaces.

Based on these observations, I could change my skateboard bearings on time, thus enabling me to remain safe and functional.

Frequently Asked Questions (FAQs)

Q: What does ABEC stand for, and which part does it play regarding bearings?

A: The Annular Bearing Engineering Committee is responsible for setting the standards for the ABEC rating. Higher ratings, like the ABEC 9, indicate greater precision and tighter tolerances, which can be helpful in skateboarding applications.

Q: What is the difference between an ABEC 9 bearing and an ABEC 1 bearing?

A: An ABEC 1 bearing is expected to have lesser tolerance and a lower level of precision than an abec 9-rated bearing. In contrast, the abec 1-rated bearings are more than capable of simple tasks; the abec 9-rated bearings have a more suitable speed and efficiency for a professional skater.

Q: Why must ABEC 9 precision bearings be used in skateboards?

A: Precision skateboard bearings that meet or exceed the ABEC 9 standards have lower friction and a higher rating than other precision skateboarding bearings, which can translate to better overall performance of skateboard wheels. These bearings help lower energy loss and provide the best experience for skaters.

Q: Are ABEC 3 or ABEC 5 bearings appropriate for high-speed skating?

A: For recreational skating, ABEC 3 and ABEC 5 bearings can suffice, though they have their limitations on precision and speed compared to ABEC 9 bearings, for those looking to perform at their very best, acquiring an ABEC 9 bearing is suggested.

Q: What materials make up high-rated ABEC bearings?

A: When looking for high-accuracy ABEC-rated bearings, say ABEC 9, it is best to go for high-quality steel or ceramic materials. Such materials allow for better durability and lower friction at high-performance levels.

Q: Does the lubrication of the bearings change the bearing performance in any way?

A: A bearing’s performance is closely related to the lubricant used, so yes, the lubricant will affect performance. When used correctly, good grease or oil will minimize friction and wear, whereas no lubrication or poor lubrication will cause overheating, which renders high ABEC-rated bearings less efficient.

Q: Are there any negative consequences of using ABEC 9 bearings?

A: Yes, they have certain disadvantages. For example, ABEC 9 bearings perform well and are very precise; however, they are more expensive than lower-rated bearings. Also, with high performance comes high maintenance. If they are to maintain their high performance throughout usage, they are likely to be more involved in maintenance and lubrication.

Q: What type of maintenance does an ABEC 9 bearing require?

A: Lubrication and cleaning are mandatory to offer suitable precision and performance for ABEC 9 bearings. Skaters have to check for debris, dirt, and other such debris periodically and apply the required lubricant.

Q: What is the effect of the ABEC ratings of the bearings on their lifespan?

A: In most circumstances, higher grades bearing ABEC ratings represent better tolerances; therefore, if used under normal conditions, these can have a longer life. However, all bearings have at least a specific life span, dependent upon parameters such as usage and care taken, environmental factors, etc.

Q: Where would I go to find ABEC 9 bearings for sale?

A: ABEC 9 bearings can be found in certain skate shops, other appropriate online shops, and grinder manufacturer sites. Bones Bearings and Wicked ABEC are among the few companies that make strong, high-ABEC-rated bearings for skaters to increase performance within that range.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8